Whether they are flours, liquid raw materials or fruit fillings and other miscellaneous goods, when raw materials are received into the production unit, sensors in the warehouse, in the silo or at goods inward determine whether they are of the quality that is required and was ordered. The system reports the results together with concrete handling instructions to the production manager and to Quality Assurance. After that, based on the collected data and supplemented by their own sensors, kneaders or mixers ensure that the plants stop automatically when the dough or batter has reached its optimum. All of this happens in real time, and the operator and/or line manager know(s) exactly what is happening on the entire plant. Artificial intelligence informs people about recommended actions, but in principle the plant controls and regulates itself, and purposefully influences the quality of the dough and thus of the finished baked article. The condition of the batter or dough is constantly recorded, accurate traceability is ensured through digitization, and as Dr. Mario Jekle of the Technische Universität München once remarked: the dough determines its pathway through the production operation. The product searches for it itself – whether it’s the right proofer with its temperature or air humidity, what is optimum for a decorative cut, or the baking time and steam input in the oven.

In the “Production facility of the future”, the optimum will be summoned from the corresponding raw materials without the personnel’s specialist knowledge. The required quality – whether it’s a baguette with particularly fine pores or a ciabatta with an artisan visual appearance, a high dough yield and an open pore pattern – the system can predict whether it’s possible, and can to some extent determine, influence and optimize. Various robotic systems also clean the plant and production facility automatically. Perhaps in the “State-of-the-art production unit”, delivery of the finished product to the customer will also be automatic – driverless logistics systems are already in use nowadays, e.g. to distribute goods within a factory.

At the same time, all the plants in the production operation are highly flexible to enable them to respond quickly to new customers’ requirements and product changes. Machines also communicate with one another and the proportion of reject goods is reduced, since the required baked products always leave at the end of the production line. The baked products always have the desired visual appearance, the required dimensions and desired weight, and the previously specified degree of browning.

It all sounds like pie in the sky – but a couple of systems like this have already been partly implemented today. Science and research, as well as the plant constructors, are already working on it, and the corresponding data is being collected and projects brought to life or have already been completed. However, there is certainly still a long way to go before we are at all able to fulfill the technical requirements.

Everyone knows that the baking sector operates using natural raw materials that are to some extent subject to large fluctuations. In the production facility of the future, however, human beings will play an ever-decreasing role, which will introduce enormous social challenges.

Regards,

Ours knows a good deal. Industry-specific processes, integration of machines and systems, monitoring and reporting, traceability, quality management and much more.

The CSB-System is the business software for the bread and bakery goods industry. The end-to-end solution encompasses ERP, FACTORY ERP and MES. And best-practice standards come as part of the package.

Would you like to know exactly why industry leaders count on CSB?

Production

08 Mecatherm: A unique oven for a changing world

12 Haas-Meincke: Diversity with a common denominator

21 Bundy Baking Solutions: Several new designs

24 Sancassiano: Hardware and software under one roof

26 Vandemoortele: Continuous investments

30 Zeppelin-Systems: A new CODOS and more

34 RONDO: Industrial bread line for artisan products 38 Tecnopool Group: From transport to process engineering 40 Handtmann: The next step

42 Reading Bakery Systems: Innovative baking technologies

94 Topos Mondial: New equipment is designed

iba

52 World trade fair: Innovations in Munich

Interview

16 Luis Videla: Pizza around the clock

92 Pierre Escarbelt: More baking cycles and higher temperature

96 Christian Tomasch: Europeanization at all levels

Raw materials handling

22 Cepi SpA: Automation and fermentation

44 Agriflex: From Trevira silos to tailor-made raw materials management

Packaging

32 Kwik Lok: Focus on food safety 86 Brevetti Gasparin: Specialists in slicing and packaging 95 Bettendorf Stanford: High speed slicing and bagging

Trays and pans

46 acs Coating Systems: New: HIFFICIENCY ® baking and roasting accessories 84 Precisma: Compact, efficient and universal Hygiene

48 Colussi: The de-luxe class from Northern Italy Refrigeration technology 78 Koma: Natural refrigerant

Inserts:

+ König Maschinen Gesellschaft m.b.H., 8045 Graz/Austria, + Kwik Lok Corp., UNION GAP, WA 98903, USA

+ MECATHERM S.A., 67130 Barembach, France

PUBLISHING COMPANY

f2m food multimedia gmbh Ehrenbergstr. 33

22767 Hamburg, Germany

+49 40 39 90 12 27 www.foodmultimedia.de

PUBLISHER

Hildegard M. Keil

+49 40 380 94 82 keil@foodmultimedia.de

EDITOR-IN-CHIEF

Bastian Borchfeld

+49 40 39 90 12 28 borchfeld@foodmultimedia.de

EDITORIAL STAFF

Helga Baumfalk

+49 40 39 60 30 61 baumfalk@foodmultimedia.de

ADVERTISING DEPT.

International sales director Dirk Dixon +44 14 35 87 20 09 dixon@foodmultimedia.de

Advertisement administration

Wilfried Krause

+49 40 38 61 67 94 krause@foodmultimedia.de

DISTRIBUTION

+49 40 39 90 12 27 vertrieb@foodmultimedia.de

TRANSLATION

Skript Fachübersetzungen Gerd Röser info@skript-translations.de

TYPESETTING

LANDMAGD in der Heide

Linda Langhagen; design@landmagd.de

PRINTED BY Leinebergland Druck GmbH & Co. KG Industriestr. 2a, 31061 Alfeld (Leine), Germany

BAKING+BISCUIT INTERNATIONAL is published six times a year. Single copies may be purchased for EUR 15.– per copy. Subscription rates are EUR 75.– for one year. Students (with valid certification of student status) will pay EUR 40.– (all rates including postage and handling, but without VAT).

Cancellation of subscription must be presented three month prior to the end of the subscription period in writing to the publishing company. Address subscriptions to the above stated distribution department.

No claims will be accepted for not received or lost copies due to reasons being outside the responsibility of the publishing company. This magazine, including all articles and illustrations, is copyright protected. Any utilization beyond the tight limit set by the copyright act is subject to the publisher’s approval.

Online dispute resolution in accordance with Article 14 Para. 1 of the ODR-VO (European Online Dispute Resolution Regulation): The European Commission provides a platform for Online Dispute Resolution (OS), which you can find at http://ec.europa.eu/consumers/odr

Valid advertising price list: 2018

cover photo: © xxx Titlephoto: © Burford

Want superior hydration without adding excess heat to your dough? New Hydrobond technology delivers. Not only does it blend dry and wet ingredients with unmatched efficiency, it also:

• Requires no additional floor space

• Reduces your total mixing time

• Cleans quickly and easily

• Reduces heat attributed to mixing energy

• Allows you to mix more dough with same size continuous mixer

BY READING BAKERY SYSTEMS

BY READING BAKERY SYSTEMS

producing company founded by the Mauri brothers on the one hand, together with Burns Philp Yeast & Bakery Ingredients there on the other. AB Mauri in its present-day form was founded in 2004 and belongs to Associated British Foods (ABF) The Group also owns the former DSM in the Netherlands and a shareholding in the German Uniferm company.

The instore oven manufacturer Wiesheu’s new Management Board consists of Marcus Gansloser (CEO) and Alexander Herz (COO). As CFO, Harald Schrode will be responsible for the areas of Finance/Controlling. Volker Groos and Dieter Tacke have left Wiesheu’s Management Board with effect as of 1 July. Explaining the change, Marcus Gansloser said “It is very important to me that we continue to further our company’s development, and constantly improve the internal communications and collaboration of and with all employees to that end. All the staff are urged to play their part to enable our performance promises to be fulfilled. To allow this to be tackled with utmost emphasis, we have set a new course in the Management Board.” +++

According to the study “Project Iced Beverages 2018” in the Allegra World Coffee portal, cold coffee is a rising trend in the British coffee shop sector. A report in the online portal Food Service says the Study sheds light on the proportion of “Iced and Blended Beverages” in the British out-of-house market of the coffee chains established in that country. According to the Study, sales revenues from “Iced Beverages” last year amounted to 370 million British pounds (GBP, about EUR 417 million). Moreover, the Study is also said to predict strong growth: the analysts expect sales revenues exceeding GBP 421 million (around EUR 475 million) in 2018, and as much as GBP 660 million (EUR 745 million) by 2022. These drinks are said to be very popular with the young generation of millennials and generation Z. According to the survey questionnaire, the most popular brands for the consumption of “Iced Beverages” are Starbucks (29%), Costa (26%) and Caffè Nero (7%). For the study, Allegra carried out more than 50 expert interviews with representatives of industry and assessed more than 2,000 online questionnaires.

+++

A second heavyweight in the yeast and fermentation industry is also acquiring further purchases. AB Mauri recently announced the takeover of two companies from the Rank Hovis milling group. Holgran, headquartered in Gainsborough, Lincolnshire, supplies malt products, seeds and various blends to the British baking industry. Edinburgh-based Fleming Howden, on the other hand, manufactures baking agents and yeasts. In January this year, AB Mauri had already taken over Specialty Blending Co., LLC in Cedar Rapids, which produces baking mixes. AB Mauri operates 50 production sites in 32 countries worldwide, and sales offices in more than 90. The nucleus was Fleischmann’s Yeast founded in the USA in 1868 and the Australian baking ingredients

FRITSCH Holding AG announced a change in the chairmanship of the Management Board at the start of the second half-year: Kirsten Lange takes over at the company’s head. According to a communiqué, she already knows the Group through her Supervisory Board work, and looks forward to taking over responsibility for the family business on a temporary basis until a suitable long-term board member has been found. Lange’s most recent post was as a member of the executive board of Voith Hydro Holding, where she was responsible for the service, automation and digitization areas. Prior to that, she worked for 22 years in the Boston Consulting Group in Germany, the USA and China, and has advised more than 20 companies in the mechanical engineering industry. She is currently a member of the supervisory boards of Heidelberger Druckmaschinen AG and ATS Automation. She studied Journalism, Politics and Philosophy to degree level in Munich, and gained an MBA at the INSEAD in France. +++

Anna-Maria Fritsch is the new President of FRITSCH USA Inc. Anna-Maria Fritsch studied “International Business” and worked in management consultancy companies for several years before joining the FRITSCH family business. She has comprehensively broadened her technical and technological knowledge and experience since that time. Fritsch has been responsible for the Marketing and Process Management departments during the past two years. In this function she focused her main emphasis on implementing strategic marketing processes and forming partnerships with reference clients. The CEO will move her residence to New Jersey next year, to be as close as possible to clients in the North American market. +++

Mecatherm will present an entirely newly designed oven at the iba trade fair. Key advertised features include precision and flexibility.

+The French bakery machine constructor Mecatherm has its production facilities in Barembach near Strasbourg. However, drumbeats from the Vosges Mountains will be heard at the iba trade fair. One of these announces an entirely newly designed modular tunnel oven with which Mecatherm is spe cifically targeting medium-sized bakeries. The businesses in focus are those wanting to process a diverse range of products flexibly but without relinquishing a differentiated heat transfer profile consisting of radiant and convection heat matched to the respective baked goods. The engineers also promise efficient processes and precise control.

This oven is aimed mainly at major chain store businesses and specialty manufacturers in industrialized countries. Here in particular, according to Mecatherm President Olivier Sergent, there has been a large growth in the demand for high-quality variety. He says this is forcing companies towards a more complex, multi-faceted production organization and correspondingly modifiable technology, especially in the baking step of the production process. It is said to be still rather a niche activity at present in other countries, but a thoroughly attractive market due to the purchasing power existing in the middle classes. However, no matter how greatly diversity and an artisan visual appearance are valued in both markets, consumers nowadays are equally unwilling to give up adherence to their quality standards.

The company’s engineers are therefore said to have been given the task of developing an oven that guarantees excellent baking quality, is precisely controllable, and can be switched over from one product to another very quickly. The design of

operability and monitoring should be as simple and efficient as possible.

The outcome is an oven that not only looks markedly different to previous ovens from Barembach – including a contribution to better hygiene – but is also a kind of heating technology all-rounder.

To understand this, one must take a look into the modularly constructed oven in which each module allows a variety of heat transfer options from above and below.

A thick perforated plate heated by a stream of hot air is suspended in the baking chamber above the baked goods, and can emit radiant heat downwards. On the other hand, blowing warm air through the holes in this plate creates an air movement that carries heat to the products being baked,

+ Convection from above and below

+ Convection from above, radiant heat from below

+ Radiant heat from above and below, hot air brings heat to the products

+ Radiant heat only from above and below

+ Radiation and convention from above, and only radiation from below

+ Radiation and convection from above, and only convection from below

i.e. via convection. The two principles can also be used in combination. In the case of the bottom heat, on the other hand, Thanks to the new patented „mobile hearth system one can decide between radiant and convection. This yields a total of six different heat transfer possibilities, and thus the right baking program for almost every product at any point in time.

The oven is divided up into heating zones with a maximum baking area of 25 m2 each. Each zone can consist of a different number of modules. The most compact oven of this kind is 17 m long, including the entry and exit zone, offers three different heating zones controllable independently of one another, and provides up to 32 m 2 of baking area, depending on the oven width.

Heating is either direct using gas burners mounted above the baking chamber, or indirectly via heat exchangers and in that case with gas or oil, depending on the customer’s preference, or electrically.

Because not only can the type of heat transfer in each heating zone be regulated independently, but also the upper and lower heat can be heated by separate air flows, a fast response is possible and the oven can be operated with extremely productspecific baking profiles. The separate control over how and where the heat is brought to the product, to what extent and whether using radiation or air movement, gives the oven extremely fast mobility and reaction, especially as the burners are correspondingly dimensioned and deliver up to 80 kW/m2 According to Mecatherm, this avoids unproductive pauses between different products. Increasing the temperature by 100°C takes just 20 minutes, and a reduction of 100°C only 30 minutes.

Zeppelin Systems GmbH

Messenhäuser Straße 37-45

63322 Rödermark, Germany

Tel. +49 6074 691 - 0

foodtechnology@zeppelin.com

www.zeppelin-systems.com

Plant engineering redesigned: We offer you the choice rather than ready-made kits – because we integrate processes, not just parts –for more efficiency, flexibility and security. Innovative plant designs from the plant architects. For a perfect dough all along the line.

Baking takes place optionally on a wire loop belt or a rod belt. Anyone who prefers to bake directly on the belt can on request have a belt preheating system to ensure that sufficient power is immediately available from below.

Each module comes with a steam inlet. For the air and steam extractors, the engineers placed value on the fact that no non-uniformity in the baking result occurs across the whole width of the oven.

Of course, even in this oven it is impossible to completely avoid a drop in temperature directly after loading the oven. But the combination of the use of a modulating burner that adapts precisely its operating rate and the rapid air change in the baking chamber ( 20 000 m3/H) permit a quasi immediate adaptation of the oven to the product load, and a very homogeneous baking even in case of partial loading;

An air management system ensures that equilibrium prevails between the air removed and the volume of inflowing air.

This is done thanks to seven regulators in total, four to extract air and steam and three for the air inflow. The automatic regulation system of the stack valve avoids both a downdraught of cold air through the flue and the blowing out of hot air into the production rooms. It goes without saying that the oven’s controller has provision for programming product-specific baking curves. The program runs at the press of a button, without the need to change slide valves or switches, which is beneficial to homogeneity when employing operators without much specialist training. To monitor the baking process, not only do the usual windows provide a view of the products being baked in the oven, but also anyone who wants to can arrange for this process to be relayed by camera to the controller’s monitor screen.

The engineers also thought it worthwhile to think about accessibility for cleaning and repairs. All the external panels can be dismantled without tools, allowing quick easy access to the baking chamber, and so can the belt drives at the be

ginning and end. +++

The competence of Haas-Meincke A/S extends from cookies to croissants – the common denominator being the ovens, especially the re-engineered IFC.

Haas-Meincke must simply love cookie monsters, since hardly anyone works so unstintingly as the engineers in Skovlunde just outside of Copenhagen on the question of how to manufacture particularly large numbers of cookies quickly and efficiently. They shape batters – even multicolored ones – on belts, cut hard cookies from laminated dough sheets, or use shiny molding rollers to give soft doughs the special appearance by which cookie enthusiasts recognize their favorite goodies. And they ensure that copious replenishments roll off the belt. Whereas in the past molded cookie lines had working widths only just reaching 1000 to 1200 mm, Meincke now offers plants with working widths up to 1800 mm, and even 2000 mm are no longer far off. With high speed, of course, the very latest hygiene designs and almost a flying product change, because in the cookie industry the combination of high line availability, perfect hygiene and simple control are also what decide a line’s efficiency.

The cracker lines are the second main pillar at Haas-Meincke. Sheeting lines, gauge rollers, cutters, recycling conveyors –and off they go like the cookies, off into the oven and, if required, after that into equipmentthat turns them into little sandwiches and/or decorates them. At the last Interpack Meincke showed a new „Jumbo line“: a very high-end equipment with massive production output (up to 6000 kg/hour) and the highest degree of sanitation and operability (open design/quick change over/on-the-fly set-ups).

But the product field for which Haas-Meincke works expanded long ago. Macaroons, soft sponge cakes, cupcakes and sponge cake rolls in all sizes are just as much their topics as crunchy cereal snacks, and they have already even helped a

The Danish company Meincke was founded in Skovlunde near Copenhagen in 1953 and has belonged to the Austrian Haas Group’s “Biscuit” division since 2009. Haas was in turn taken over by the Swiss Bühler Group in 2017. Haas brings together in this division the parts of the company dealing with cookies, crackers and cakes. Haas-Meincke produces industrial plants to manufacture soft and hard cookies, pizza, crackers, sponge cake rolls, bread, cereal products and fine pastries in Skovlunde near Copenhagen. The ovens are made in Rødkærsbro on the mainland of Jutland. The “Biscuit” division comprises two other factories in Leobendorf near Vienna and Etten-Leur in the Netherlands. The division’s sales in 2016 were approx. EUR 107 million, and it employed around 300 staff. The division builds and installs around 100 projects each year. More than 1,500 of the division’s production lines are operating worldwide today. There are subsidiary production works in Brazil, China and India.

few bread products and bread-like products into a production line, regardless of whether it’s crispbread, cinnamon buns or bagels.

Their primary common denominator is their range of ovens, consisting of indirectly heated convection ovens (IFC) and all combination of hybrid ovens using directly gas fired and/or radiant sections in the first sections.

A fully newly re-engineered version of the IFC oven will be on show at the iba trade fair in Munich. The baking chamber’s insulation is reinforced by a layer of air, which ensures that the oven’s outer skin stays completely cold. Together with Copenhagen Technical University, they have also developed a new heat exchanger whose air dampers can now be adjusted independently of one another, thus allowing very efficient air flow control, which in turn considerably improves heat exchange.

All the ovens are supplied in working widths of 800 to 4400 mm and subdivided into sections two meters long. As a rule, a heating zone consists of several such sections. A blower draws air out of the oven to achieve a uniform distribution of heat in the oven. The exchange of air is in turn controlled via holes above and below the belt carrying the products, thus achieving a uniform baking result across the whole width of the oven. Fast temperature change and adjustment and thus efficient heat transfer is possible because air is blown directly onto the products. Haas-Meincke also offers a facility to control the air humidity in the oven as an option for all oven types.

Each 2-meter section is fitted with a large door for inspection, cleaning and servicing, and these are on both sides of the

oven at an oven width of 1500 mm and above. Depending on the customer’s preference, the oven’s cabling is either integrated into the oven or mounted externally.

For improved cleanability, the baking compartment height has been enlarged by 50 mm, thus creating more space under the belt. There’s no longer any need for anyone to suffer a dislocation to remove product residues that have fallen down and would otherwise be a fire risk. There is also a wash-down model of the oven, mainly for the US market.

The purpose of the gap control, an option available for all Haas-Meincke’s ovens, at the start of the oven is to raise the efficiency of the line (less waste and energy-saving). If the measuring instrument detects that there is no product currently running through the oven, all the flap valves are for example shut tight and are not opened again until product is on its way in. The energy recovery concept pursues a similar goal, including by ensuring that moisture leaving the oven with the hot air does not simply escape through the flue. Instead, the heat is transferred via a heat exchanger and into the incoming fresh air supply.

Again at the iba trade fair in Munich, Haas-Meincke is showing a high-speed wire-cut system that is not only able to process heavy doughs, but also leaves intact lumpy inclusions such as nuts or chocolate chips. The machine’s top, usually a fixed installation, is fully demountable on this machine and can be pushed onto a so-called roll-on-roll-off stand. This allows either a complete exchange or removal for cleaning to take place at lightning speed, which is an aspect that is important especially to safeguard against cross-contamination during a product change. With a 2-meter working width and 300 strokes/ minute, the 6110 is in the high-performance class among wire-cutters.

The subject of protection against unintended input of allergens is at the very top of the priority list in the cookie and cake sector, which is why some of the machines in Haas-Meincke’s pilot plant look as though they are still incomplete. But that’s not the case at all. In fact, when ordering a plant, a number of customers immediately include an extensive specification sheet dealing with sanitary design, and often this includes omitting covers and claddings that make no sense from the safety point of view. Visibility and accessibility for cleaning also top the priority list, and sometimes it’s even necessary to install transparent plastic or safety glass instead of steel doors and claddings. Then the easier accessibility frequently also has a beneficial effect during a product change, because now only complete assemblies are swapped. With the new GF3 rotary molder, a full changeover of the web can be completed in only 13 minutes, where 30 minutes is usually the „good benchmark“ level“. +++

Brevetti Gasparin designs and manufactures systems for the SLICING and PACKAGING of baking products, with the purpose to satisfy and answer specifically to the customers needs to optimize production processes of end of line with reliable, functional and guaranteed solutions.

The company produces single machines and automatic industrial lines tailored and able to meet all market segments thanks to the personalization and customization of the systems according to the highest productive standards.

Founded in 1960, Brevetti Gasparin has matured on its over 50 years of experience a deep knowledge of the market able to guarantee for each product typology the right technique of slicing and packaging for an excellent result on the final product, with the interest in a continuous improvement abreast of the customer needs and the market evolution.

The study and design of specific solutions and the ability to listen and interact with its customers, enabled it to be on the market today to make the difference!

f2m have spoken to Luis Videla , the CEO-Owner of Grupo Almar.

+Borchfeld: Mr. Videla, can you tell us more about the Grupo Almar?

+ Videla: Grupo Almar started in 2002 with 1 shop in Buenos Aires, close to where the bakery is now located. This area was an old private airport and we bought one of the hangars and converted that into a bakery. We started with producing cakes. Within the first 3 years, the company grew from 1 to 16 shops. Because labor was getting more expensive, we had to reconsider the business structure. Also, because we supplied products for different supermarket chains. By 2013, we had 700 employees in the plant. Because then we didn’t had production machines, our production capacity was limited. That was the reasons why we bought production machines: for Medialunas (Argentinian croissant) and Pizza, we bought a Rademaker Croissant and Pizza line. We also have a breadline from Mecatherm. This development made us increase the production capacity x10, while we could drop back the labor from 700 to 290.

Our last investments were a tin bread line, a bun line with a capacity of 9000 kg/hour and we upgraded our cake line. We now have a total product scope of 200 products. In 2014 we started franchise chain shops, and we now have up to 50 of these shops. In 2018 we will have a total of 80 franchise shops.

+ Borchfeld: Do you produce pizza around the clock?

+ Videla: We produce pizza in 3 daily shifts, and we have the Pizza line up and running up to 20 hours a day. Then

Grupo Almar bought from Rademaker a multifunctional Pizza line, that besides pizza bases, can also produce flatbreads and crackers. This way there are able to double their profits coming out of their Pizza line. Grupo Almar is a creative bakery that establish itself by getting more products out of a production line. In total Grupo Almar produces 200 different products. 8% of total production in the plant consists out of pizza products. Ice cream individual sticks is the company’s latest expansion.

between the next production run, we have 4 hours to cool down the oven and to clean the production line.

+ Borchfeld: How positioned the company itself in the market today and where can customers buy the pizzas?

+ Videla: Our philosophy is to produce a lot of volume at a low price. Our customers can by our pizzas at our own franchise shops and at Supermarkets. We supply pizza’s in Buenos Aires and other areas of Argentina. Our bakery is positioned in the middle of a civilian area and we have a shop directly at the factory. A lot of people from the area come here to buy their products.

After the mixing process, the dough batches are put into a Chunker low stress sheeter combination to create a continuous dough sheet. A Quick Reductor reduces the sheet’s thickness for the first time. The cross roller rolls the dough widthwise, to increase eventual its width. 2 Gauging Stations reduce the dough thickness further, before the dough sheet is transferred towards the Rademaker proofing system. Here the dough creates its cell structure and develops taste.

After proofing, the dough sheet is cut and pressed into Its final shape. Several sizes and shapes can be produced. The excess dough is automatically collected in bins and placed back into the dough mixing system. This way there is no dough waste.

Finally, the tomato sauce will be deposited onto the pizzas.

3 Stripes of sauce are deposited onto each individual pizza. The tomato sauce is spread over the complete pizza by a rotating sauce leveling device. The sauce is smoothened spread over the pizza, leaving the rim free of sauce. The pizzas now run towards the oven where they are baked for 80%. After baking, the pizzas are cooled down and packaged individually into transparent, plastics bags. Ready to be sold. +++

+ Borchfeld: What products do you produce and how much per year do you produce?

+ Videla: Like said, we produce a total of 200 different products. In total, we produce 1.200 tons of kilogram products per month. Our bakery produces both Fresh and frozen products. The pizzas that we produce, are what we call Pre-pizza, which are pizza bases topped with tomato sauce. These are pre-baked up to 80% packed individually and then sold. Customers can then top the pizzas and bake them their selves at home. This is the cheapest way for our customers to consume pizzas. The big difference to Europe, is that in Argentina a frozen, topped pizza costs around EUR 10,- in

the supermarkets which is for most Argentinians too much to spend on a mean. We offer customers the opportunity to consume pizza at a fair price.

+ Borchfeld: How do you describe the pizza market in Argentina? Is the market growing?

+ Videla: Topped pizzas (boxed) are for most Argentinians too expensive to consume. Therefore, the market for complete topped Pizzas is not so big as in the rest of the world. The freezer to freezer way of pizza distribution doesn’t sell here, par-baked, frozen and baked in the shop does sell. With our concept, we sell 200 pre-pizzas for one topped pizza in the supermarket. So, we think that we address the market the right way. It proofs when you look at our sales. And we still see growth in this way of offering our pizzas to the customers.

+ Borchfeld: Would you describe yourself as number 1 in Argentina, who are the competitors?

+ Videla: We would not describe ourselves as the number 1 in Argentina, but more as number 2. Our largest competitor is Bimbo.

+ Borchfeld: What products are particularly successful and why? What trend do you see?

+ Videla: For us as a bakery, the baguette line is most important, followed very closely by the Medialunas line. There for sure is a growth in the croissant market. Trends that we have here, are different than Europe. For example, there is no trend for clean label. Here in Argentina it is very much a price driven market; sell cheap or don’t sell at all. 95% of the population buys products that have a cheap price, and don’t choose much for quality products. To produce volume, you need to have a good price.

+ Borchfeld: Where do you see the company in 5 years?

+ Videla: We look ahead for 2 years with our bakery. And there we see an expansion that can feed a maximum of 80 franchise shops. At this moment, the traditional bakery and pizza market exists for 94% (mini family owned local bakeries) and only 6% out of large bakeries like Grupo Almar. But the market is slowly shifting as a natural growth of industry vs artisan

bakery is taking place. A local bakery is shrinking in floor space, a general of 100 square meters for a shop including the oven space. Therefore, we see a growth towards more market share and expansion coming up in the upcoming years.

+ Borchfeld: How did you come to Rademaker-Lines?

+ Videla: I met Rademaker on the IBIE show in Las Vegas back in 2006. From then on we had contact and started seriously talking about our plans and Rademaker’s contribution towards that.

+ Borchfeld: How does the cooperation with Rademaker from Europe works?

+ Videla: We can honestly say that it is very good, we are very satisfied with our co-operation with Rademaker. Rademaker has the best After Service in the market. I guess there is an estimate of 2 to 3 contact moments per year in which we update each other about what is happening, but on a service level we have more contact periods. Our technical department has direct contact with the Rademaker Service Direct department in case there might be a technical issue or spare-part need. As for the machines, we are operating in 3 daily shifts and the Rademaker machines have proven to be highly reliable, well designed. Maintenance is made easy due to good cleaning access.

+ Borchfeld: Mr. Videla, thank you for the interview. +++

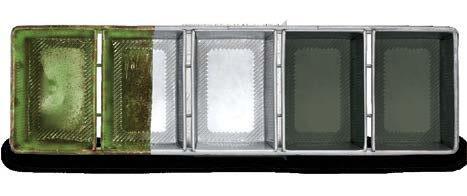

Bundy Baking Solutions is an American company with a family of brands that includes American Pan and Shaffer Mixer.

+Bundy Baking solutions is the USA market leader in the area of pans, trays, and coatings. American Pan manufactures stock and custom baking pans for foodservice, plant and industrial bakers. They offer their own proprietary coatings on their bakeware, including DuraShield, OptiShield, AMERICOAT, and Flexicoat. American Pan and offers pan refur-bishment services with four locations in Europe.

At iba, American Pan will be featuring several proprietary designs including:

+ TabLock Baking Screens : These screens are high strength steel frame with interlocking rib design that allows pans to stack while protecting the baking screen to increase the pan’s life. These baking panels are available in solid or any perforation pattern or size. These screens constructed using a tab-lock attachment system for easy and economical replacement of baking screens without rivets, drills or metal shavings. Most screens can be changed in less than two minutes.

+ ePAN designs : These are the strong and lightweight, while being energy-efficient bun and roll pans. According to American Pan, the ePANs reduce energy costs while improving proofer temperature control because they heat and cool faster as much as 25% faster pan rim cooling than traditional pans. This decreases the space needed for pan cooling. The high tensile strength of the ePAN’s aluminized steel minimizes the potential for pan damage and extends useful life. The light weight ePAN can weight up to 50% less than a traditional pan.

+ SMART Pan Tracking System : There will be a working model of the tracking system on site. This system is compatible with existing equipment and provides bakeries with valuable and precise data to monitor pan coating life and

efficiency. The pans are laser-marked with a unique 2D code and pan number. Pan sensors and tag readers are installed onto baking equipment and sends information to a database which is used to create usage and performance reports. Data collected provides reports on: line activity, pan coating life, product yield, and line efficiency. + Pan refurbishing services: with 4 plant locations in Europe (Spain, Romania and 2 in the UK), and others in the North and South America, American Pan has the ability to service global market. American Pan offers cleaning, straightening and recoating of millions of pans every year. Prolonging the life and performance of pans helps control costs in manufacturing companies around the world.

+ American Pan will also be launching their stock pan program for the UK and Europe.

Part of the Bundy Baking Solutions family includes Shaffer which manufactures horizontal dough mixers for industrial bakeries with batch sizes from 400 to 4000 lbs depending on the product. Shaffer offers triple roller bar mixers for bread, buns, and other yeast products, single sigma and double sigma arm mixers for cookies, crackers, granola, energy bars and many other products.

In addition to the American Pan products at iba, Shaffer Mixers will be revealing their new Select Series Mixers. These new designs have been precisely engineered to offer maximum value and durability. The all stainless-steel construction combined with watertight enclosures and an open frame under the bowl provides a ultimate mix of simple and sanitary design. The mixer’s single end drive system and simple operator controls are comprised of well-known, commonly-stocked components that make the mixer easier to operate and maintain. The tilt system can be configured for forward only or forward and reverse tilting of the bowl. Select Series Mixers are available in triple roller bar or single sigma arm models. +++

www.bundybakingsolutions.com Hall B1, Stand 201

The Italian silo constructor Cepi SpA focuses on automation and the growing interest in fermentation plants on the part of bread bakers.

O utdoor monolithic silos, indoor silos, both made from panels and the patented Trevira silos, and a new metering system for small sized amounts of ingredients that meters from several hoppers into a fixed-position weighing pan, which grant a faster discharge and high precision in dosing, will be the hardware highlights on Cepi’s stand at the iba trade fair in September.

Fermentation plants and automation strategies are the second focal point. According to Sales & Marketing Manager Frida Lega, the company has been building fermentation plants for a long time. Up to now it has been a segment that has rarely taken center stage internationally in relation to customized project planning. According to Lega, it should come to the fore to a greater extent. She says the growing interest in high-quality artisan products on the part of industrial manufacturers beside the rationalization of the production have spurred the demand for fermentation plants. Cepi offers sourdough plants with a variety of cleaning systems. According to the project, they can varies between a pipe recirculation of product itself, or complete CIP technology with tank systems that flushes pipework and vessels with cleaning fluid and clear water. If required, Cepi can also supply a pigging system that removes adhering materials particularly thoroughly, especially from pipework.

Up to now, the Italian company has produced mainly bulk handling systems for the food, chemical and pharmaceutical industries, including patented antistatic Trevira silos, as well as stainless steel outdoor silos for food powders, with a vibrating cone or fluidized bed for complete extraction of product on the first-in-first-out principle. There are also sugar mills, metering plants for fat and micro-ingredients, and bread, both dried

and liquid, or biscuits rework systems for the confectionery and baking industries. Cepi also supplies a flour-cooling system using pre-cooled air blown in silo through its fluidizing bed.

Most of the components and all kind of silos are fabricated in-house. Vertical production integration across all plant systems is currently around 60 %. Around 80% of sales, which reached EUR 25 million in the past year, were

and to Asia. A worldwide sales and service organization has been established.

The company’s own electronic and electrical design department in which eleven programmers and designers work on automation solutions, together with ten designers and assemblers who are responsible for the layout of the electrical systems, should be helpful in this respect. The control system they have developed offers the ability to access and analyze the plant and

Endlessly unique. A whole galaxy of variety, with your success written in the stars.

A few years ago, Oripan, a software house that could show one of the first Industry 4.0 installations, became part of Sancassiano group, the Italian mixer manufacturer. Sancassianos most conspicuous feature in hardware terms is the new bowl tipper.

+According to Andrea Agosti, one of four minority shareholders of the Italian mixer manufacturer Sancassiano, where he works as Area Manger: “The trend in the baked goods industry worldwide is towards diversified high-quality products and thus to precisely defined requirements applicable to mixing technology.” So Agosti sees growth potential for his own company to a lesser extent in continuous dough production, although Sancassiano also serves this market with its own continuous mixer.

Instead, in relation to hardware, the mixer specialists from Roddi, Italy, place greater emphasis on developing nuanced mixer types like the Kryos, built specifically for doughs that must not be exposed to a large evolution of heat. Other examples include the GRE (Revo) for cookie doughs and firm batters, or the new generation of planetary mixers. The most important innovation, however, is the new bowl tipper launched on the market last year, whose speed, drop height and emptying angle can be programmed for each individual dough. All four will be exhibited at the iba trade fair in Munich in September this year.

According to Agosti, the bowl tipper is an example of the way supposedly marginal changes can show thoroughly positive results. The dough transfer speed, drop height and

the rate at which the dough flows out of the tipper can all be programmed depending on the dough. There is also an option to specify if and when the emptying process is assisted by a scraper. To match this, for artisan products, there is a patented hopper that portions the dough downstream in large chunks with no degassing effect.

Taken altogether, according to Agosti, this reduces the stress on the dough, especially for doughs with a high dough yield and long fermentation time.

Ever since the “Genesi” design guideline came into force at Sancassiano in 2010, all the mixers made in Roddi have been built in such a way that the mobile bowls are interchangeable between all mixer types. The mixer tools are mounted in the mixer head without any visible screws or bolts, and are sealed in such a way that the mixer chamber can even be treated with a high-pressure cleaner. The mixers have also been provided with floor clearance and inclined rather than horizontal surfaces to ensure less contamination and easier cleaning.

All gearboxes have been banned from the mixer’s upper area and relocated to the region at the back to ensure a higher level of production safety without any oil reaching the dough. The spiral, twin spiral and Revo-mixers use an inverter to transfer power. “Wash-down” capability of the tools and mixer head is guaranteed in all cases. If the whole mixer is made from stainless steel, this even applies to the entire machine.

One exception to the interchangeable bowl style is the Kryos, a mixer that operates with a fixed-position bowl surrounded by a cooling jacket. The Kryos, which uses vertical mixing tools similar to the Hydra, is especially suitable for firm doughs with a TA (dough yield) below 155, such as pretzel or bagel doughs, as well as for frozen products including croissant, Danish or puff pastry doughs. Dough temperatures of 14 – 16°C can be maintained, thanks to the temperature control ensured by the double jacket. Because the mixer can also be put under vacuum or pressure, it is also usable for mixing based on the Chorleywood principle. According to Agosti, that’s one of the reasons why there is such a demand for the Kryos, particularly in countries influenced by the Anglo-American baking tradition that often worked using sponge doughs in the past.

The Revo mixer comes from a quite different area of work. Sancassiano developed it specifically for cookie and cracker doughs, thick batters and doughs in which little gluten development occurs, or none at all. According to Agosti, the market for these products also growing, and with it the demand for this mixer type, not least because the machine can use a wide spectrum of tools, from a cutter tool to a whisk.

One discussion topic on the iba trade fair stand will probably be the development already push-started by Sancassiano umpteen years ago when Oripan became part of the group. With support from the state and the scientific community, Oripan started an ambitious project with the purpose to integrate and to interconnect the production lines with the company processes according to the world wide standard Industry 4.0.

The system makes this data available to customers at a variety of processing levels. Based on a Guide, it shows line operators what is happening and where, and where action by them may possibly be needed. The data is also available to the production management for inclusion in the Manufacturing Execution System (MES) and to be linked to the Enterprise Resource Planning system (ERP). Agosti says: “It’s important to us that our customers, through the comprehensive analysis of their existing processes, can see and implement improvement potentials.” The first comprehensive installation has been operating in Italy for more than a year. +++

Vandemoortele is one of the leading manufacturers of frozen baked products. The works in Eeklo, Belgium, is among the company’s biggest locations, where 300 staff working 24/7 produce a wide variety of frozen baked goods.

+Vandemoortele N.V., Ghent, Belgium, is a company group employing a total of around 5,200 staff and pro ducing and marketing frozen baked goods together with margarines, cooking oils and fats in 35 production facilities in 12 European countries. Annual sales revenues are around E UR 1.4 billion, and the group is constantly expanding

For example, the company invested in a completely new fac tory in Kutno, Poland, in 2016/2017. However, a part of the company’s philosophy is continuous investment in existing production facilities, e.g. including in the works at Eeklo not far from Ghent, Belgium.

Site Manager Nick Clauwaert is responsible for more than 300 employees working at the latter site. The production facility was built on a green-field site between 1998 and 2000 and manufactures frozen Danish pastries and other laminated dough products, e.g. apple and nut turnovers or croissants in various weight ranges, on four lines working round the clock. The total number of different products is around 200. The Eeklo factory’s maximum production volume is up to 40,000 tons/year, the size of the total production area being around 16.600 m 2 with enough space for an extension.

Around 29% of the frozen baked products are exported to Germany, which makes that country the main outlet for products, followed by the consumer countries Belgium, the UK and the Netherlands. A proportion of the production, e.g. spicy Danish pastries with various meat fillings, is also exported to the USA.

•Hygienic Wash-down Design

•Lower Formula Cost (Scaling Weight & Dough Conditioners)

•Toolless Design Reduces Time for Clean Up & Changeover

•Up to 150 Cuts per Minute

• Lower Maintenance Cost

•Servo Driven

Burford’s seeders, toppers, sifters and pan shakers are a perfect match for our Bun Divider

We have been making Make-up Lines for over a decade. We listen to you, the baker, and innovate. Come & Experience the next generation at IBA 2018.

In total four lines are installed, physically separated from one another. The plants are supplied from a shared raw materials warehouse. Wheat flour is stored in five outdoor silos. Site Manager Nick Clauwaert explains: “The fact that the individual lines are physically separate has advantages, e.g. when cleaning the machines, since there is no need to interrupt or obstruct production in other areas. Installing new plants or components in the factory is really a challenge, however, because there is limited space in the existing production facility.” It goes without saying on the part of the Vandemoortele Group that there will be continuing investment in the existing works. For example, a new fine pastry plant made by a Dutch manufacturer has just been commissioned. Here again, the fact that the plant had to be installed in an existing building was a challenge, but Nick Clauwaert is pleased with the result. The Site Manager generally takes care to ensure that new plants are as flexible as possible, to allow them to adapt quickly to new requirements and to enable them to make the maximum number of different products. This is also why plants from a variety of different manufacturers are in use. The company has also invested in other production areas. For example, robots now help in the automatic packing of frozen dough pieces. These then go into the frozen food warehouse, which has capacity for 3,000 pallet storage bays.

Clauwaert has a clear answer to the question about market chances. There is a growing demand for mini-products weighing 25 g. Nowadays, many consumers ask about baked products with reduced sugar and salt content. To enable repeated fast adaptation to customers’ wishes, therefore, it is especially important that the Vandemoortele Group constantly invests in new technology, thus allowing it to continue to offer customers baked products with the best flavor, best quality and best service. +++

++ Around 300 employees operate four lines producing laminated doughs for a wide variety of frozen baked goods

Vandemoortele recorded a continuing positive business trend. 5.1% sales growth compared to the previous year was generated across the whole group of companies in 2017. The Recurring EBITDA was EUR 119 million, and the Recurring EBIT was EUR 63 million. Vandemoortele Germany increased sales in Germany and Austria by as much as 10% to EUR 220 million. The frozen baked products business area reached sales of EUR 871 million in 2017, which is a 5% increase compared to the previous year. According to the company, the positive result in the sector is reflected in continuing improvements in the entire added value chain, and was achieved through organic growth. It says the margarine, oils and fats business area also successfully increased its sales by 5% to EUR 549 million in a difficult market environment. About EUR 57 million was invested in 2017, including expanding and modernizing production facilities. +++

Zeppelin-Systems GmbH is an international market leader with regard to continuous dough mixing. The Rödermark-based company will present a new CODOS generation at the iba trade fair.

New drive technology, new cooling, Washing in Place, a nd of course also a new control system that communicates with Zeppelin’s higher-level automation and digitization software. Zeppelin Systems has granted the Codo a complete makeover, after more than 100 n ow, have been in service in baked goods production worldwide.

The previous asynchronous geared motor has been swapped for a water-cooled servo drive with a single gear reduction, which means not only a 40% weight saving but also a reduced installed length, i.e. space is saved and on top of that, energy consumption is reduced. Furthermore, with immediate effect there is an emergency stop function on all plants, which instantly brings it to a standstill.

The cooling system of the CODOS NT has also been fully redesigned. The efficiency level of the trough cooling has been improved considerably, which ensures better heat transfer. All the trough cooling assemblies will be positioned outside of the CODOS in future.

Moreover, with assistance of research at the Cereals Research Institute in Rehbrücke, the geometry and spacing distances of the mixing tools themselves have been optimized again.

According to Michael Piepenbrock, Zeppelin’s Business Unit Manager, Food Processing Plants: “That provides more power and performance with less energy consumption, and makes the CODOS scalable.” There will be a CODOS NT 160 with a dough production capacity of approx. 3 tons/hour, the

CODOS NT 200 with 4 – 5 tons/hour and the CODOS NT 230 with up to 8 tons/hour of dough. In 80% of all cases, a CODOS stage will be combined with a DymoMix that supplies pre-mixed, uniformly wetted raw materials to the CODOS. A two-stage CODOS solution is usually used when processing flours containing extremely high gluten levels.

Of course, Zeppelin is also moving towards digitization in its control technology. The very closely interrelated topics of automation and digitization will be combined under the MIRA brand name in future.

This means for the CODOS NT is that control will still take place via the existing Prisma Web system. However, the Prisma Web system will be incorporated into the MIRA concept in the near future. Topics, such as data analytics and cloud capability are already being developed. Whether it’s Cloud in the Web or a local solution can be chosen freely. The development focuses on the future solution’s easy applicability and scalability. Another important element are MES functionalities, which play an important role in MIRA. In concrete terms, that means input, output, energy consumption, process times, etc. are documented and can be called up and analyzed at any time. Moreover, a mobile terminal device can be used to view the documentation belonging to the Zeppelin modules, and spare parts can be ordered, if necessary. A remarkable aspect of all of this is that the Zeppelin landscape has no problems incorporating even components that do not originate from Zeppelin. In order to be able to use

this technology also in already existing plants, it is sufficient to retrofit the plant positions in question with a “beacon” which records the corresponding data and feeds it into the system.

In future, the CODOS NT will be installed on load cells in order to carry out some measurements. On the Zeppelin both you can already experience “hands on” the entire MIRA system consisting of the MIRA Control and MIRA Connect.

“Simple” hardware improvements sometimes find it hard to gain a hearing with so much IT around, but looking into that area is also worthwhile, because they directly improve reality. For example, Zeppelin will show a new series of models of water mixing and metering devices, a new manual weighing station, a new diverter valve and a new rotary valve in Munich.

The new generation of rotary valves and diverter valves for the medium-pressure impressively show Zeppelin’s new design language, clearly and powerfully drawn, with lighter weights and more powerful performance than ever before, and EHEDG has not been forgotten either. In this respect, Zeppelin is consistently going down the road of digitally networking every component, and thus MIRA Connect (formerly: PLANT.GATE) is also on board as standard.

Saves even more energy. And is ahead in most other aspects, too. Your next MIWE roll-in e + 3.0.

Unique: atmospheric baking. Makes you independent of climatic conditions

Flexible baking characteristics: MIWE delta-baking

Is stingy with energy

– from connected load to overall efficiency

Bakes to perfection: core temperature sensor

Ergonomically brilliant: soft close door, remote display, large screen

++ Al l the components will be fitted with a “Beacon” as standard in future. This will record process data and forward it to a higherlevel controller. This data can then be evaluated. They can also be retrofitted to plants made by third parties and to existing plants. The “Plant.Gate” tool can be used to read out this data

Zeppelin is at the iba trade fair in hall B6, booth No. 351. The Italian machine manufacturer Tecnopool is right next to Zeppelin´s booth, and Zeppelin and Tecnopool will jointly present design concepts for entire production lines. +++

For nearly 70 years Kwik Lok ® Corporation has created solutions to closing bags that has been used throughout the world in the consumer goods industry. This simple yet innovative little card seamlessly secures the end of a filled bag.

+The advantage of the Kwik Lok ® closure is that it is quick and easy to apply and reuse. With focus on food safety, sustainability and technology, Kwik Lok ® closures give extended reach beyond a simple bag closure, it also provides business-building opportunities.

The Kwik Lok ® Corporation is constantly working towards sustainability. The bag closure is designed to easily be reused and recycled. Kwik Lok ® is actively engaged in reducing its’ global footprint with clean process and environmentally conscience efforts to minimize energy demands. For example, Kwik Lok ® cools its extruders within a closed loop cooling system. Additionally, the closure does not use hardeners or additives in the plastic.

Kwik Lok® provides the technology to close bags, print required information on the closure, and apply label in one motion. These metal-free Kwik Lok® closures allow for the use of metal detection as the final step after packaging the product. The closure system can be combined with bag sealing machines to apply a weld seam, so both supplier and customer can be sure the product has not been mishandled.

Kwik Lok® printing capabilities extend beyond UPC and matric codes – build a brand promotion with customized labeling and messaging to see measurable increases in sales. Tip Top

Bakery Brands saw a 15% increase in sales, with consumer recall of 85%.With easy application and high-resolution laser printing, increasing brand awareness is easy.

Manufacturing

In addition to ease of use, the machinery required to apply the closure to packaging is simple.The shape of this closure is what makes it work. The Kwik Lok® high-speed bag closure system provides customers with automation, speed, reliability and custom printed bag closure labels.Kwik Lok ® provides the technology to close bags, print required information on the closure, and apply label in one motion for up to 120 film bags per minute.

Kwik Lok ® also offers other equipment like conveyors, bag tensioner, closure printer separator for hand bagged products, and printing solutions for bagged packages. The company makes bag closures and equipment for fully automated packaging lines as well as semi-automatic and hand applied closures. In addition to film bags, the Kwik Lok ® closure systems can also be used on burlap and paper bags.

Additionally, Kwik Lok® offers a roll-in/roll-out stand for flexible use for their label capabilities. This mobile stand can be used to try out the equipment in the facility, providing ease of use and testing without major modifications to the existing facility.

iba

At iba, Kwik Lok ® will be demonstrating their new ink jet printer (Model 904) that features an easy to use touch screen. The high-resolution printer has the ability to print QR Codes and 2D barcodes. It features quick replace industrial sized ink cartridges. Additionally, it has the ability to print 120 closures per minute with only one moving part. +++

The Swiss company RONDO Burgdorf AG presented a new universal bread line to visitors at an open-house event in Schio, Italy. The plant can produce sliced/cut, long-molded and round-molded artisan breads and bread rolls.

R ONDO Industrial solutions, RONDO Burgdorf AG’s industrial division, organized an open-door day in Schio, Italy, for European production managers. The company presented the newly-developed ARTISANA bread line to the expert audience. The plant can produce sliced/cut, long-molded and round-molded artisan breads and bread rolls. As explained by CEO Dr. Michael Witzak during the practical demonstration of the plant: “The RONDObot is also the only system worldwide that can round-mold doughs with a dough yield of 180 or more.”

The plant begins by forming a dough sheet, for which RONDO uses the ASTec design of the universal MIDOS dough sheeter (Multiple Industrial Dough System) supplied with dough via a bowl tipper. A roller system developed specifically for soft to firm doughs creates a homogeneous dough sheet without using process flour or process oil. This is followed by a satellite head, cross-roller and calibrating station to produce the required dough sheet thickness and width. A built-in automatic weighing device ensures that the weights of the made-up pieces are as accurate as possible. After cutting and spreading apart the dough sheet, and separating the dough pieces, the RONDObot comes into operation. This is the basic technology for a novel round-

molding system for dough sheeters, and its task is to prepare round-molded artisan and “ordinary” rolls and breads in a wide range of weights. The round-molding system consists of the RONDObot, an industrial robot with an IP67 design, novel interchangeable tools (these tools are changed automatically), and a special round-molding table. The RONDObot’s six degrees of freedom enable optimum matching of the round-

molding process to the dough and end-product, and replicates round molding with 100% repetition accuracy.

Round-molding in the multi-phase rounding process is divided into individual phases, in each of which the molding movements are carried out in the same way as a baker would perform them manually. The plant enables not only the adjustment of the molding speed but also a definition of the changes in the eccentric movements and the pressure on the dough piece. All the parameters of the multi-phase rounding process are stored in the plant’s controller and can be called up again.

The plant can process artisan rolls and breads in a weight range from 40 to 1,000 g. It can also process wheat doughs and doughs with a proportion of rye or seeds. In particular, doughs with a long dough rest time can be made up through the plant. Thus, as was explained to participants during the event, the RONDObot is the only currently available rounding system that can achieve good molding results with doughs containing large amounts of water and with a prolonged pre-proofing time. Basically, the RONDObot can be integrated

RONDO ASTec lines are designed to meet the highest hygiene requirements. Fast, safe plant cleaning is ensured by the hygiene-friendly design and construction, and by the use of high-quality materials. ASTec lines are cleaned according to a computer-assisted program individually defined for the respective production facility. The cleaning steps are logged and recorded for possible audits. ASTec lines are available in two versions: one for dry cleaning and one for wet cleaning. An advantage of ASTec lines is a reduction in cleaning times by up to 30% compared to other plants. On the one hand this leads to reduced costs, and on the other to increased production time. +++

into existing or new bread and roll baking lines. This round-molding system is the RONDObot’s first application. Dr. Witzak explained that RONDO is currently considering automating additional dough processing steps. The RONDObot can also be bypassed to manufacture long-molded and cut/sliced products on the ARTISANA.

However, the new plant’s practical application was not the only thing that was presented during the event. The role played by the topic of Industry 4.0 in the RONDO company was also explained to the visitors. Dr. Witzak presented the RONDOnet, in which production and plant data are collected in a cloud. Users receive an overview, e.g. about system alarms, the operator or the plant’s capacity utilization. All the events are recorded online and stored in the cloud. Machine incidents, e.g. a plant start or stop, have a date/timestamp and a value. All the components can send warning or fault states at the same time. These messages can be forwarded to the internal service or directly to RONDO’s service team. According to Dr. Witzak: “If the system has an ERP connection available, these messages can also trigger an order for spare parts.” In this respect, RONDO supplies a servicing plan for each component, which should be complied with to guarantee faultless functioning. Moreover, the plant can be equipped with up to four webcams to monitor the progress of the production operation. An analysis tool currently being developed should, in the near future, allow the number of products and

their dimensions and color to be established. As Dr. Witzak explained: “Preventive maintenance with proactive alarms and online event recognition is the first step towards the target of nil downtimes for our customers.”

The open-house event in Schio allowed participants to take a look at the company’s new developments. More information about the industrial bread line for artisan products will also be available at the iba trade fair in Munich. +++

The Tecnopool Group, at one time mainly a conveyor belt specialist, is increasingly making a name for itself as a process technology supplier.

D oing one thing but not giving up the other – that’s how the development of the Italian mechanical engineer Tecnopool in San Giorgio in Bosco near Padua could be described.

Tecnopool is still regarded as a specialist in a wide variety of steel rod belts for product transport. For the past two years, however, Tecnopool has expanded its field of activity and built a thermo-oil-heated spiral oven in which hot oil circulates in pipes under the levels of the spiral. Due to the way the spirals are built, the pipes run under one level and above the next. This allows the products being baked to receive radiant heat from both. Whether the oven has a circular or oval construction, and whether the belt entry and exit are at the top or the bottom, is decided by the customer, and so are the oven’s height and thus the number of spiral levels. To achieve a specific time/heat profile for a product, the oven can be divided into temperature zones with separate oil circulations. If required, convection heat is provided by a heat-exchanger in the center of the oven, supplied with hot oil and with a blower.

Depending on the need and the customer’s requirement, each oven has its own heating plant, but central oil heaters are also an option. There is a choice between various steel rod belts to convey the items being baked, depending on whether baking is to take place directly on the belt, on trays or in pan clusters. The spiral oven’s possible performance spectrum is broad. Plants with a capacity of 500 kg/hour for

gluten-free products, and toast-bread plants with an hourly capacity of up to 4 tons have been built up to now.

Thus the oven builds on conveyor belt technology specific to Tecnopool, which is employed mainly in the global baked products industry where up to now as a rule it has been used in proofing and freezing plants or deep freeze. The aspect which makes Tecnopool’s belts rather special is that the drives are installed in an easily accessible position and do not need to be lubricated. In addition, they run really quietly and even in reverse if necessary, which also allows the plants to be used as buffer storage.

++ Spiral ovens also bake pan clusters

The secret is in the connections between the steel rods and what drives them forwards. The rods are welded to steel elements whose ends are attached to sliding elements that in turn run on rails. The shape of the guide track prevents the belts from jumping out of the guide. They are driven forwards by wheels that engage in the chain guide from the outside, one spiral and one drive wheel on a separate drive shaft for each level. This ensures that each level is pulled uniformly, and excludes jerky movements. The drive wheels are the only things that need to be serviced. Whether one or more motors is/are used depends on the height of the spiral tower.

This kind of drive technology frees customers and the designers from the need to build circular spirals in every case. Ovals are equally possible, as are systems in which the belt spirals upwards then moves downwards again inside the upward-moving first spiral, so the entry and exit are both located at the ends of the spiral near the floor.

The spiral oven is not the only thing that set in motion Tecnopool’s transformation to a process technology supplier. The company, still majority-owned by the founding family Lago, took over the Slovenian bakery machine builder Gostol-Gopan D.o.o. Tecnofryer S.L.U. in Valencia, Spain, which produces industrial fat frying plants, has already belonged to the company for some time. +++

Hall B6, Stand 230

Almost everyone in the industry knows the Handtmann dough divider from the VF Line. An add-on device that afterwards shapes the divided dough will be shown by the Biberach-based company at the iba trade fair.

A n outstanding feature of the VF dough divider is its precise pre-portioning of batters and doughs by a vane cell feed system in which a vacuum assists uniform product infeed. The doughs are afterwards gently conveyed as a continuous filling stream and pre-portioned at the same time.

The dough dividers are usable in combination with attachments to cut/divide, mold and meter a variety of bread types, e.g. from wholegrain breads made from rye, wheat and spelt to gluten-free baked products, pizza doughs, toast- and sandwich-breads, cookies, baked snacks, ethnic food such as naan breads etc. Gentle feed material conveying ensures that sensitive raw materials such as added olives, seeds and nuts are not crushed, and the structure of the dough is also retained undamaged.

At the iba trade fair, Handtmann will show how the VF 800 dough divider pre-portions dough and feeds it to the FS 520 molding system’s powered filling stream divider with its six outlets. The servo-driven filling stream divider ensures accurate weights for each row and product at the same time, thanks to accurate rotor revolution speeds. Products are molded into the required 3-D shape by a rotating perforated plate system with easy-change formatting attachments plugged on at the outlet. Possible options include spheres, cylinders, small rods, droplets or other 3-D shapes with a product diameter up to 65 mm. Products can be pre-portioned directly onto trays or even into a fat-fryer at a cycle rate of 45 pieces.

The product shape is displayed via the dough divider’s controller, meaning it can be chosen easily, after which the process parameters are calculated. Handtmann’s presentation with this combination at the iba trade fair will include processing gluten-free doughs, ryebread baguette rolls and “Vinschgauer” flatbreads, an Austrian regional specialty.

In another combination, Handtmann will show the VF 800 dough divider in conjunction with the SE 442 and SE 443 cutting systems. Doughs for which the SE 442 is suitable include those for naan bread, toast-bread and pizzas, as well as gluten-free doughs. It is fitted with a pneumatically-operated knife and can reach a high cycling performance that depends on the dough piece weight, dough consistency and the dough divider that is used. The 443 cutting system is normally used to fill tinned breads directly and precisely into baking pans. The VF 800 and SE 443 combination operates oil-free, thus enabling of low-viscosity doughs to be pre-portioned accurately.

Handtmann’s iba presentation is rounded off by various equipment for accurately weighed metering of fillings and toppings onto dough sheeter lines or into containers. +++

Sveba Connect part of Middleby Connect - cloud solution.

New S-Series combination oven.

New Prover F500.

Updated rack oven C252 with core temperature.

Professional young bakers in the Sveba Dahlen bakery. Swedish ”fika” in the stand. Glimek Bread line.

V-Series rack oven updates. Middleby Bakery Group.

Reading Bakery Systems (RBS) is one of the world’s leading manufacturers of baking and process systems, especially in advanced high production cookie, cracker, biscuit, snack (baked chips, pretzels, expanded snacks, and bread snacks) and pet food systems.

Reading Bakery Systems brands include: Thomas L. Green, Reading Pretzel, Exact Mixing, and Reading Thermal. Reading Bakery Systems is also part of the Markel Food Group Company.

At iba they will be featuring several new baking technologies and innovative snack systems including a new Exact Mixing HDX continuous mixing system for buns on the show floor as well as and feature the new Thomas L. Green Servo Wirecut Machine, new Emithermic cookie oven and Reading Thermal oven profiling solutions.

At iba, Exact Mixing will display an HDX (High Development) Continuous Mixing System for buns. The mixer is designed for manufacturing highly developed dough at low temperature like buns, breads, rolls, English muffins and other ultra-high absorption doughs. This two-stage system is designed to mix all ingredients in a uniform mass with a twin-screw mixer in the first stage. In the second stage, the dough is kneaded to the proper development level with a single screw mixer. The HDX mixer is shown to create more consistent color and height in buns and rolls, while reduce energy consumption

compared to batch mixing. This continuous system helps eliminate batch to batch variations. In addition to consistent product, food safety is optimized since dough is not exposed to environment during mixing. All of this and can handle dough production rates from 1,500 to 10,000 kg/hour.

Exact will also highlight other models available for a wide range of snacks and other bakery products including the new MX Mixer with Hydrobond Technology. The new Hydrobond Technology ensures instant, even hydration of a dry ingredient stream prior to entering the continuous mixer. Without adding heat to the dough, a uniform hydration is accomplished and results in shorter mixing time, therefore requires less energy. The MX Mixer is the most versatile mixer that Reading Bakery Systems offers and is suited for a wide range of products including: snacks, cookies, batters and pastes. According to Reading the MX Mixer is also an ideal first-stage mixer for processes that require creme up and pre-blended stages.

Reading Thermal will be featuring the Thermal SCORPION® developed for bread and bun bakers. The SCORPION® 2 System provides measurement system to capture the 4 key baking

parameters: temperature, air velocity, heat flux, and humidity. In addition to tracking these parameters, it also simplifies the baking process kill step validation as it allows bakers to collect 5 product core temperature measurements and automatically generates a kill step validation lethality report.

The SCORPION ® 2 System includes the Pan+Dough Probe and the Temp+Airflow Sensor Array. To help bakers achieve consistent bake cycle S-curves, the Pan+Dough probe is a fixed position dough interface/core temperature measuring device to provide accurate and repeatable data. The Temp+Airflow Sensor Array is used to both profile temperature while also profile airflow across the width of large tray and grid conveyor ovens. The information gathered from this system are useful in adjusting a process to maximize product consistency and quality while reducing waste and improving baking efficiency.

Reading Bakery Systems will also feature several innovative baking technologies at iba used for cookies and other snack products including:

+ Servo Wirecut Machine- This new machine offers more control and flexibility as well as better safety features and easier sanitation. With up to 300 cuts per minute (cpm) it is designed for cookies, biscuits. Even with the speed it maintains high degree of accuracy and consistent

piece weights. Adjustments are made easy with an integrated touchscreen. Sanitation and maintenance improved with 50% less parts than standard wire cut machines. Wash down parts can be removed without tools. RBS SafeShield® Program is integrated to prevent injury including with light curtains that stop machine when curtain is broken.

+ PRISM Emithermic Oven Zone- This newly designed oven offers radiant and convective heat, with a humidity controlled product zone directly surrounding the product while baking. Particularly for cookies and biscuits, this provides better control over product development and spread and is more efficient than traditional recirculating heat and cyclothermic zones.