Hear first-hand from an unprecedented line up of Ministers and mining CEOs TOP SPEAKERS CONFIRMED SO FAR INCLUDE: See the full list at www.miningindaba.com #MI2023 BOOK BY 1 FEBRUARY FOR YOUR LAST CHANCE TO SAVE! 6-9 February 2023 CTICC, Cape Town

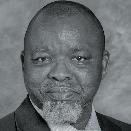

Hon. Gwede Mantashe Minister of Mineral Resources & Energy Republic of South Africa

Duncan Wanblad Chief Executive Anglo American Group Mark Bristow CEO Barrick Gold

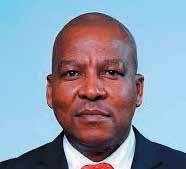

Hon. Lefoko Maxwell Moagi Minister of Mineral Resources, Green Tech & Energy Security Republic of Botswana

Andre de Ruyter CEO Eskom

Benedikt Sobotka CEO ERG Resources

Hon. Paul Chanda C. Kabuswe, MP Minister of Mines & Minerals Development Republic of Zambia

Sinead Kaufman Chief Executive – Minerals Rio Tinto Rohitesh Dhawan CEO ICMM

Hon. Dr Abdirizak Omar Mohamed Minister of Petroleum & Mining Somalia

Tom Palmer President & CEO Newmont Corporation Roger Baxter CEO Minerals Council South Africa

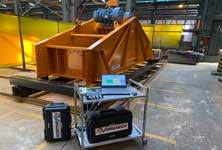

Cover Image:

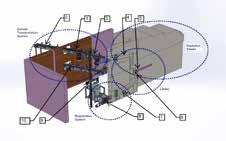

Carl Hamm’s Turnkey Dewatering Solutions for African Mining Projects

COVER STORY: PG36

Effective Dewatering, Compliant and Productive Mining

Carl Hamm Pipes Pumps

Solutions is committed to delivering the best possible customised turnkey dewatering solutions to solve challenges that mining companies face on-site as they are increasing output. Carl Hamm’s involvement helps mining operations focus on their core business and rest assured about high quality and backup service.

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za

+ 27 10 055 3356

Anita Anyango

anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Editor’s Note

The devil is in the missing details

For those not in the know, South Africa has made the installation of Collision Avoidance Systems (CAS) on mining vehicles compulsory. This follows the approval by the Department of Mineral Resources and Energy (DMRE) gazetting of Level 9 Vehicle Intervention Systems for Collision Avoidance in Mining (read a concise article inside this edition).

As expected, advocates of safety in mining such as unions and advocacy groups have lauded the move, almost running short of superlatives. But the trend of laws designed to promote safety in the mining sector is a source of great concern. Typically, the laws are passed with much fanfare and not adequately enforced. A case in point is the persistent problem of acid mine drainage in Johannesburg and surrounding areas.

Generally, there is a perception that regulations are flouted with giddy abandon and culprits get away with murder or go scot-free. And how does the regulator react?

At best, the offenders get a fine that is only a slap on the wrist; at worst, nothing is done. In the end, they continue breaking the law with impunity, safe in the knowledge that they will not face any dire consequences.

Now, the question is whether the DMRE will mobilise enough resources to ensure the legislation on compulsory usage of CAS, and crack the whip.

Small wonder, analysts are curiously observing how the Department will enforce compliance. Currently, this is yet to be outlined, as they say: “The Devil is in the Missing Details.“

Nick Barnes editor@miningbusinessafrica.com

Susan M. susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire winnie@miningbusinessafrica.co.za

+27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng

angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts Precious Chirunga accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

Art Director/Layout

Augustine Ombwa

Arobia Creative Consultancy

austin@arobia.co.ke

+254 772 187 334

Circulation/Sales info@miningbusinessafrica.co.za

+ 27 10 055 3356

Published By Media Icon (Pty) Ltd

38 42 02 CONTENTS January - February 2023 Media Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. www.miningbusinessafrica.co.za

TEAM

18

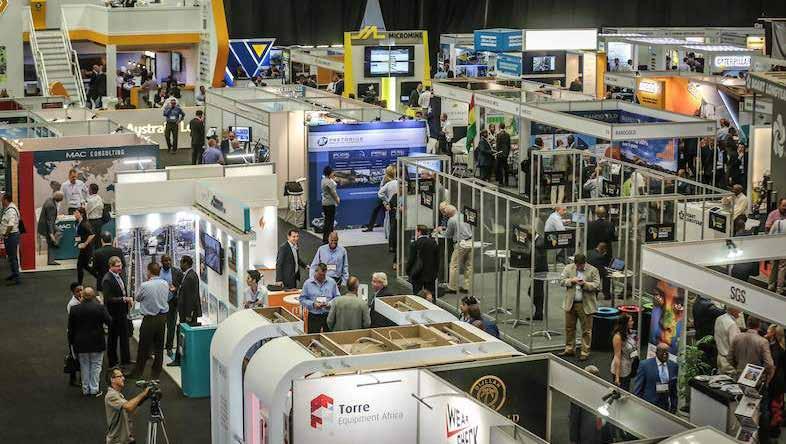

Investing in African Mining Indaba 2023 Special Edition

Unlocking African Mining Investment: Stability, Security, and Supply

Simon Ford, the Portfolio Director of Hyve Group, fields questions from Mining Business Africa (MBA) on the relevance of the 2023 Investing in African Mining Indaba’s theme to contemporary trends in African mining, as well as the in-person events.

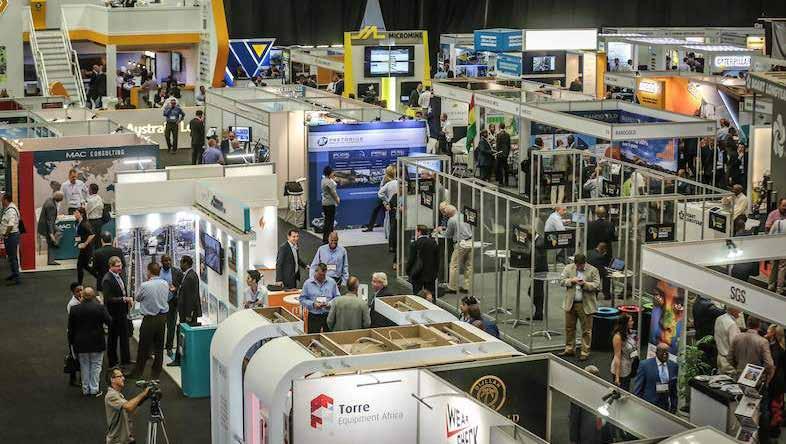

MBA: After a two-year hiatus, the Investing in Mining Indaba returned in 2022. How is the mining industry’s response to this year’s event?

SF: Overall, the response has been extremely positive. We saw a record-breaking Indaba in May 2022 that set the tone for the industry and for post-pandemic events as we lead up to February 2023. We are seeing a lot of early commitment and we are encouraged by the interest we have already received. With commodity prices remaining strong, and demand for critical minerals, battery metals and rare earths accelerating we can expect this to translate to another bumper turnout and we are excited to be back to our regular dateline in February.

MBA: What changes have you introduced to ensure that the event meets delegates’ expectations and is more relevant to the current trends in the global mining sector?

SF: It is wonderful to be able to gather, once more, in Cape Town for the world’s largest mining investment event and as always, we are hoping for a blockbuster lineup of speakers, including key government leaders and policymakers, corporate leadership, investors and thought leaders. With the Mining Indaba’s integration of 121 Group, we are in an even stronger position to serve our thousands of delegates with bespoke meeting programmes between investors and junior miners as part of their Mining Indaba experience.

2 Mining Business Africa | January - February 2023 FEATURE

A beehive of activity at the 2022 event

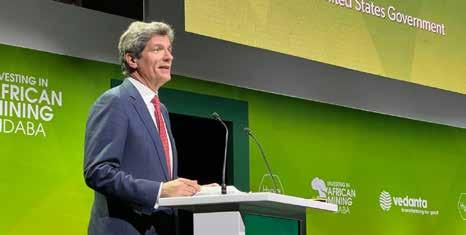

The President of Zambia, Hakainde Hichilema, giving a keynote speech in 2022

One particular programme we are excited about for 2023 is the Explorers Showcase, where we hope to showcase early-stage explorers through presentations and core samples to help stimulate those much-needed conversations with investors. This ensures we can now claim to be driving investment into every stage of the mining production cycle through explorers, to juniors and on to mid-tiers and major mining companies.

It’s a great initiative, supported by the Department of Mineral Resources and Energy, South Africa, and will also help to support their exploration drive. To complement this, we will run the Junior ESG Forum as well as our ESG Awards. Please also look out for our new dedicated area for Junior Miners, aptly named the Junior MINE.

For the first time in 2022, we held our dedicated Infrastructure & Supply Chain Forum bringing together the vital mining supply chain companies with senior mining executives to discuss ESG-focused solutions to Africa’s growing mining operations. Such was the success of that programme, we have integrated it with our technology-focused Mining 2050 stream, to create the new three-day InfraTech

Delegates

Mining 2050, Sustainability Day, Young Leaders Forum and the General Counsel Forum.

MBA: You have chosen the theme of ‘Stability, Security and Supply for the 2023’ event. What is the rationale behind this?

SF: As the world cautiously emerged from the global pandemic in 2022, we rightly focused on getting Africa’s myriad economies back on track. Whilst ESG, from investment to operations and social licence to operate, will continue to underpin the values of Mining Indaba, we find ourselves entering a new chapter in both pan-African and global economies. Therefore, February’s official theme will be: “Unlocking African Mining Investment: Stability, Security, and Supply”. This captures the very real geopolitical shifts and economic disruptions we are experiencing, which are providing pressure points – as well as opportunities – within African mining. Due to this situation, global economies are seeking the security of supply, especially for their energy transitions, as well as the raw materials and precious metals to bolster their economic power.

Mining Business Africa | January - February 2023 3

@ Indaba content platform looking at critical aspects of mining infrastructure, technologies and building effective supply chains.

will also benefit from our mainstay content streams during Indaba week including Main Stage, Ministerial Symposium, Intergovernmental Summit, Green Metals Day,

Leaders of some SADC countries graced the event with their presence

FEATURE

MBA: There has been an observation among some analysts, which is a bone of contention, that virtual events will replace the traditional ‘in-person’ format in the near future. What is your take on this? What do you think makes ‘in-person’ relevant for events of the Mining Indaba scale now and for a long time?

SF: One of the key disadvantages of virtual events is the lack of in-person interaction. For almost two decades now, the Mining Indaba has brought the mining community face-to-face. We know the industry thrives on being together, making connections and sharing information. That is not easy to replicate in a virtual environment.

In 2021 we ran Mining Indaba as a two-day, content-led event, which was a huge success under the circumstances. We secured over 6,000 registrations from around the world and

had three African heads of state give keynote addresses. In addition, we also ran our Mining Indaba Virtual Investment Programme in March 2021, allowing mining companies the opportunity to meet with global investors and continue to drive investment into African mining. There is no replacement for live events though and in May 2022 Investing in African Mining Indaba returned as an in-person event after two years and welcomed a record-breaking 6 570 attendees to the CTICC, in Cape Town, South Africa.

We are delighted to be returning to Cape Town in 2023 as a purely in-person event in its original February spot in the calendar from 6-9 February.

MBA: What opportunities or developments in mining do you see sustaining the hosting of events like Investing in Mining Indaba in the coming years?

SF: One of the most immediate benefits of hosting international events like the Mining Indaba is the impact it has on the local economy. It is often difficult to fully appreciate the economic impact of any major event so after the Mining Indaba in 2020 we worked with a South African research body, Stratecon, to conduct an in-depth report on the economic benefits of hosting the event in South Africa.

We found that Mining Indaba increased GDP in South Africa by R177m of which 80% was from international sources. We created 274 new jobs in South Africa, 233 of which were in the Western Cape and we helped increase national taxes by R22m, R18m of which was from international sources. So, the direct impact is certainly significant, and we are committed to increasing that further over the coming years by growing our events.

MBA: Last but certainly not least, what is your message to the delegates who will be attending The 2023 Investing in Mining Indaba as well as mining industry stakeholders?

SF: As the name suggests, Investing in African Mining Indaba has a core strategic remit focusing on bringing investment opportunities into the African continent. The conference provides a platform for mining majors, mid-tiers and juniors to discuss key industry issues. Mining Indaba also creates opportunities for exploration companies to network and engage with important investment stakeholders and government all under one roof.

4 Mining Business Africa | January - February 2023

A discussion on a topical issue at Investing in African Mining Indaba 2022

The use of Corflex Pinch Valves at the DRD Ergo Operations in South Africa

In 1978 the Anglo American Ergo Operation started on the eastern side of Johannesburg in South Africa for the recovery of pyrite containing gold, uranium and sulphur from old gold mines slimes dams of which there are many as mining of Johannesburg area has been going for many years.

Johannesburg is one of very few cities not built on a river. It was actually built on a river of gold extending +/- 150kms east to west.

The valves originally installed on the ERGO slurry pipeline was plug and ball types but these were found to be maintenance intensive. Many other valves were tried as alternatives including sliding disc valves a manual operated non-return ball valve and Corflex Pinch Valves.

Corflex Engineering was in the process developing high-pressure pinch valves for pipelines handling abrasive product. Pinch Valves are an ideal slurry valve as in the fully open position they are similar to a rubber lined pipe. When closed and not allowed to leak they can last for many years.

The Corflex Pinch Valve Sleeves originally had problems of failure due to pressure from water hammer but this was overcome by using stronger reinforcement for the rubber sleeve. To enable this special tooling was built. As the sleeves are hand-built Pressure testing of the sleeve for safety reasons was also started which is set at twice the maximum recommended

working pressure. Sleeve failure is in excess of three times the recommended working pressure.

In 1986 5 x 350mm Corflex Pinch Valves were installed in a major pump station at a pressure of 20 Bar. The flushing valves were eccentric plug valves. These proved to be maintenance intensive and later the manifold was lowered and 4 x 350mm Corflex Pinch Valves installed.

The pump station ran like this until it closed in +/- 2005. In 1988 Ergo Daggafontein and Simmergo operation was developed.

In 1988 the sleeve had been strengthened enough for 350mm Corflex Pinch Valves and 400mm on Pig Launchers to be installed on all Slurry operations for pressures up to 30 Bar (+/- 435 PSI) 200mm Corflex Pinch Valves were used to charge the pig launchers. The majority of ERGO pipelines were 450mm where the velocity was 1.9m/sec so the velocity through 350mm pinch valves was over 3m/sec.

Also supplied were 250mm for pressures up 40 Bar (+/- 580 PSI) and 450mm valves at 16 Bar (+/-232 PSI). This new operation increased ERGO slurry pumping to +/- 4,000 000 Tons per month. In 1990 two 300mm Corflex Pinch Valves were installed at a Booster Station at a pressure of 50 Bar (+/- 725 PSI). These two valves ran for 15 years with only one sleeve being replaced due to being punctured by a piece of metal as the valve was being closed.

Corflex Engineering (Pty) Ltd

Two 300mm Corflex Pinch Valves were installed on the inlet side of two banks of 8 Pumps for pressures up to 25 Bar (+/- 360 PSI). These valves had no failures. In 1988 Rand Mines developed the Crown Mines Operation to recover gold, uranium sulphur from slimes dams around Johannesburg and in the west. Corflex Pinch Valves up to 500mm were installed in all slurry applications up to pressure of 25 Bar. Both ERGO and Crown Mines continued to use Corflex Pinch Valves for all their slurry applications. In around 2005 Anglo American stopped its ERGO operation. This was subsequently taken over by Crown Mines. All equipment that could be salvaged including Corflex Pinch Valves were put back into use. There are many Corflex Pinch Valves of all sizes which have been operating in both operations since 1986 which to date is some 36 years. Most of the Corflex Pinch Valves are hydraulically operated because of high pressure. In some areas where fail safe is required the pinch valves automatically close and act as a non-return valve.

Corflex Pinch Valves supply Pinch Valves suitable for higher pressures than any other similar valve. The Corflex Pinch Valves have continued to show that they can safely handle high pressures with low maintenance for long periods of time on slurry pipelines.

Mining Business Africa | January - February 2023 5 FEATURE

Corflex Pinch Valves for high and low pressures in abrasive slurry applications.

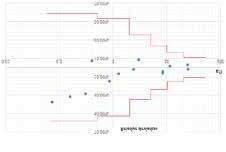

Turning Risk into Competitive Advantage

“Mining companies can turn the risks that Environment, Social and Governance (ESG) issues pose on their operations into competitive advantage through improved reporting on key materiality factors which impact the sector, impact investors and all critical stakeholders. Active management of ESG reporting will translate into positive investor sentiment and ultimately into long-term sustainable returns. Credible data from reliable ESG ratings can support informed business decisions which, in turn, will allow sustainability to materialise into an invaluable asset. Data analytics provides management and the Board with a tool to assess its internal capacity and risk appetite, thereby allowing it to set its risk tolerance levels based on budget, available resources and strategy.”

Above represents a snapshot of the advice from the experienced team at Risk Insights (Pty) Ltd to mining companies in South Africa and in the region. The team is equipped with the first machine learning and Artificial Intelligence ESG sustainability rating tools - ESG GPS for rating listed companies and A-Cubed for unlisted companies. These tools provides a consistent, transparent and independent view of a company’s ESG readiness taking into account global best practice and specifics / regulation while presenting multidimensional by factor analysis on E, S and G.

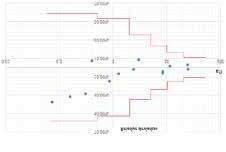

Findings of the Ernst and Young Survey allay any misgivings – if they had been any - that mining companies in Africa may have had about the significance of sound management of Environment, Social and Governance (ESG) to the long-term sustainability of their operations. The survey, Top 10 Business Risks and Opportunities for Mining and Metals in 2022 Report, highlights that top global mining executives rank Environment, Social and government (ESG) as the number one amongst risks and opportunities businesses will face over the next twelve months. The results were drawn from data collected from a yearly survey involving over 200 global mining executives. Others in the top three are decarbonisation and Licence to Operate (LTO). Interestingly, LTO topped the list in the 2021 report.

The report resonates with the viewpoint of Mr Andrey Bogdanov, CEO of Risk Insights (Pty) Ltd, an international professional data science firm. Risk Insights has extensive experience and expertise spanning fields as diverse as capital markets, risk management and data science. The firm`s professional Data Science Lab uses cutting edge techniques and has built the first AI-powered machine learning ESG rating tool

for Africa by Africans. In 2020 and 2021, the company was awarded the prestigious World Economic Forum Awards, in 2022 company was recognised as Best ESG Data Provider in Africa by the Environmental Finance. Risk Insights provides ESG sustainability ratings to diverse clientele across the Globe.

Four aspects in reliable reporting

Risk Insights notes that ESG reporting is a relatively new requirement in South Africa as well as across the continent, although the mining sector, especially large blue-chip entities, have had ESG policies and reporting embedded in their operations for several years. For this reason, Mr Bogdanov says the firm is keen to utilise its Data Science Lab comprehensive data sets to address growing requirements of mining companies for international best practices in ESG reporting, their materiality disclosure and ranking within their respective peer groups to assist in positioning mining companies to fully materialise competitive advantage related to ESG as the world moves toward carbon neutrality. He is certain that, through comprehensive reporting, mines can formulate and implement strategies which will make their

operations more sustainable going forward. Specifically, he cites three fundamental aspects which can facilitate reliable ESG reporting: the leading role of the board and management (topdown approach); the business re-engineering process; and engaging experienced experts, as ESG is a complex subject matter.

• The board and management at the forefront ESG reporting must be empirical relevant, material, transparent and easy to track to be credible, and so, it is not surprising that it takes up more time and resources. Accordingly, Bogdanov recommends that, for ESG reporting to be more embedded in an organisation’s operations, its setup must follow both ‘top-down’ and a bottom-up approach. “ESG should be driven from the board and management level into the entire organisation and entrenched into the culture of a company while education needs to be provided to all levels in the organization,” says Mr Bogdanov, underlining a mindset change as a critical process, as it can determine the effectiveness of ESG’s aligned strategies and policies.

6 Mining Business Africa | January - February 2023

FEATURE

• Business engineering process

Successful ESG reporting relies on a rigorous business engineering process, which culminates into the change in the culture of an organisation. ESG affects several parts of an organisation’s value chain, to name a few, supply chain management and measuring carbon footprint Scopes 1, 2 and 3 (both direct and indirect emissions). Specifically, what is reasonable from four perspectives – the company, the industry and the employee and society. Certain processes within the mining company may be responsible for more emissions and therefore to assist reporting and impact the trade-off charts using data analytics for measurement and monitoring could differentiate one mining company against another.

Robust business engineering processes result in strong, transparent and effective reporting thereby mitigating risk and creating opportunity and competitive positioning. ESG reporting is translated in the integrated reports as well as voluntary and mandatory disclosure of companies.

• Engaging credible experts

Given the complexity of ESG and its impact on the various stakeholders and the value chain, engaging and employing specialists with a credible track record in the field is key. Hence, it is critical to engage specialists who can train, develop and educate on ESG matters and ensure embedding it into the organisation on all levels,” advises Mr Bogdanov. One of the risks that Risk Insights has noted in South Africa is a repurposed approach when it comes to appointing individuals on ESG related positions which have very little experience or training on ESG.

Core business imperative, not an option

Indeed, all told, the importance of sound ESG reporting in the current operating environment cannot not be overstressed as the world devises strategies to protect the planet and contribute towards carbon neutrality. Ongoing developments have rendered sustainability into a core business imperative, and not an option.

• Stakeholder accountability

Stakeholder capitalism is here to stay.

Increasingly, different stakeholders are holding mining companies accountable for environmental, social practices and governance (or malpractices). Sustainability became part of the day-to-day life in all forward looking companies positioning themselves for the new era of governance.

• Direct bearing on bottom-line

What makes ESG rating more relevant is its bearing on the bottom-line of a business. From a brand and reputation perspective, it translates into financial measurement through share price and market capitalisation. For instance, ESG scores can impact an organisation’s valuation. Impact investors apply larger discounts on companies that have lower ESG scores.

“Having a good ESG score means that a company embeds the principles of inclusivity and stakeholder management into its strategy, operations and human capital management making a company more sustainable. It translates, via brand and reputation management viewpoint, into a competitive advantage affecting the cost of capital and cost of debt of a company,” Mr Bogdanov points out.

• Positive legacy

Finally, by doing more to ensure the long-term, sustainable economic and social growth of the region in which they operate, mining companies can leave a positive legacy beyond the life of the mine.

Prioritising ESG more

By and large, the burden is on mines to turn the risks that ESG factors pose to their operations into competitive opportunities and positioning to demonstrate their commitment to sustainable business practices. Risk Insights would like to see “African leadership actively translate value as conscious leadership into good for current and future generations. Leadership must pivot to change the world and the ways we operate when it comes to CO2 emissions, water pollution, taking care of communities, inclusivity and much more. Mining is one of the closest to earth industries”.

Risk Insights has blazed a trail with Africa’s first machine learning and Artificial Intelligence ESG sustainability rating tools - ESG GPS and A-Cubed suites of products. So far, ESG GPS has been used to rate all listed companies in South Africa, Nigeria,Kenya and Mauritius. More markets to come in 2023.

Mining Business Africa | January - February 2023 7

Mr Andrey Bogdanov, Principal and Interim CEO of Risk Insights (Pty) Ltd, a Johannesburg-based boutique professional risk management data analytics firm

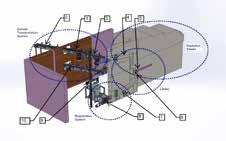

Sensor-Based Intelligent Mining Operation - Level 9 Collision Avoidance Systems

The leap to Level 9

‘Zero-Harm’ and maximum productivity is possible with Probe IMT’s integrated CAS solutions

Safer mining is about integrated risk management and safety protocols in a range of areas. Proximity detection and Collision awareness is a crucial focus area in the drive to reduce fatalities, contributing to the levels of protection against the risks associated with vehicle interactions on a mine. If implemented holistically, rapidly advancing proximity detection and collision awareness systems (CAS) create not only a safer, but also a more productive mine. This is thanks to advanced sensing technologies, sophisticated rules and intelligence and the wealth of data the systems are able to gather, analyse and feed back to the mine operators, says Gert Roselt, CEO of Probe Integrated Mining Technologies (Probe IMT).

Leading the way

South Africa is leading the way in the drive to implement the highest levels of collision awareness systems (CAS) to the Earth Moving Equipment Safety Round Table (EMESRT) Vehicle Interaction Defensive Controls Model Level 9 (intervention controls), where electronic systems automatically slow down the machine and apply a controlled stop if a dangerous interaction is detected when the operator has failed to take evasive action to the prior Level 7 (Operator Awareness) alarm and Level 8 (Advisory Controls) alerts. The mandating of Level 9 CAS for trackless mobile machines (TMM) in underground and surface mining in South Africa is now mooted for December 2023, as indicated by Dr Sizwe Phakathi, Head: Safety

and Sustainable Development at the Minerals Council South Africa, ahead of Electra Mining 2022. The International Council on Mining & Minerals (ICMM) aims to eliminate all fatalities from vehicle interactions in mining by 2025. Roselt highlights that collision avoidance ranked top of 13 different technologies identified by 47% of mines globally and 57% of mines in Africa as expecting to see significant investment in the coming two years based on the 2022 GlobalData survey. “With 30%-40% of mining industry deaths globally attributable to failures of vehicle interaction controls, this is no surprise. Advances in collision awareness are arguably already showing results - with one TMM related death reported this year to date in South Africa.”

8 Mining Business Africa | January - February 2023 FEATURE

The team leading the drive at Probe IMT

Major leap

The Level 9 standard is a major leap from Level 8, which required systems to deliver an advisory instruction to operators. Now, electronic systems must automatically take mechanical control of the vehicle and slow down and apply the brakes at any mine where there is a significant risk of such collisions. “Implementing reliable integrated systems that can comply with Level 9 requires long term commitment and solid investment in sophisticated CAS systems that provide high integrity object detection, operator warning and automatic intervention, when necessary, in order to prevent an accident,” says Roselt. “It must be far more than a box ticking exercise, with integrated technology implemented in a holistic way that avoids the challenges of operator alarm fatigue, sensing technology inaccuracies, unnecessary alarms during normal operations and reduced system availability – all of which can impact production.”

According to Roselt, if Collision Awareness solutions are implemented holistically, the data collected from multiple sensors related to the potential incidents drives enormous value for safety and productivity, especially when Artificial Intelligence (AI) and Machine Learning (MI) can be applied. For example, traffic flows can be managed and optimised to maximise production, he says.

“At Probe IMT, we have been working with carefully selected industry-leading solutions to help our clients ensure that they can meet the requirements of the Earth Moving Equipment Safety Round Table (EMESRT) Level 9 intervention controls using the mining industry developed ISO-21815 protocol.”

Wabtec’s value-added partner

Probe IMT is a value-added partner for Wabtec Corporation. “The Wabtec Collision Awareness Solutions Suite is a sophisticated and adaptable collision awareness and reporting system developed specifically for the mining industry with the aim of making mining operations safer, while helping to ensure optimal performance at a lower sustainable cost,” says Roselt. “Software algorithms that are able to interpret and anticipate the complex vehicle interaction scenarios presented during normal mining operations enables the Wabtec systems to operate seamlessly with the operator based on human centred design for new mining technology. Using advanced technology field hardware and communications software, with real-time system health monitoring and event reporting, the Wabtec Digital Mine’s safety technology provides industry-proven reduction in vehicle interaction risk. With the right reporting and analytics tools to monitor and manage operator behaviour, safety culture and compliance can rapidly be improved.”

The surface offering can be deployed with a variety of proximity detection methods including

GNSS, radio frequency (RF), VLF magnetic and cameras to provide one of the most effective high integrity systems on the market. The vehicle display unit includes touch screen HMI, with graphics display of remote objects showing ID, range, speed and heading with configurable audible, voice and visual alarms. Robust wideview cameras eliminate blind spots with auto switching on direction of travel and to zones of object detection. Further features include equipment health monitoring, maintenance tracking, blending, and production reporting.

A strong differentiator is the high integrity proximity detection using high accuracy GNSS augmented with time of flight (ToF) RF combined with real-time monitoring and connectivity provides 360˚ protection for vehicles, equipment and personnel. Strategically placed proximity units afford operators unparalleled situational awareness - contributing to improved safety levels on-site. Back-to-base reporting provides interaction reports, journey replay, hot-spotting, geofenced exclusion zones and alarm events, safety adherence reports and system health monitoring.

Roselt explains that this whole-of-mine safety aid is OEM independent as a stand-alone system. This means it is fully configurable and adaptable to site specific requirements, but still offers low total cost of ownership. CAS extensions can include integration with Driver Fatigue Monitoring Systems, Fleet Management / Dispatch Systems, machine vision and Asset Performance Management for mobile equipment.

Setting new standards

“We believe these solutions set new standards for workplace safety and facilitate ‘zero-harm’

objectives and productivity objectives through effective, reliable and intuitive operation,” says Roselt. “Ultimately, CAS Level 9 enables the safety of all personal in mines, and safer mines ultimately become more productive mines in the long run. Supported by robust and mature implementation of Levels 1-8, mines should carefully select implementation partners and technology to ensure a smooth transition.”

working around the globe. In a recent published blog by Ballard, that number of trucks emits 68 million tons of CO2 (MtCO2) each year, the same as certain countries such as New Zealand or Finland. Decarbonizing all those trucks would be like removing the impact of 150-million gasoline-powered cars off the roads.

If you are considering fuel cell vehicles, there are considerable benefits for mining’s off-road vehicles, according to Ballard. There are fewer regulatory requirements and certifications compared to on-road vehicles. Larger mining and construction companies may be able to reduce costs by ordering in quantity and leveraging economies of scale. Centralized hydrogen refueling can be built on site, and potentially renewable hydrogen can be leveraged on site to generate green hydrogen to be used as fuel for vehicles.

Certainly, those of us who are stakeholders in Africa’s mining industry can appreciate such efforts surrounding Africa’s hydrogen roadmap, and we look forward to hearing more about the hydrogen fueled haul truck as Anglo American’s experience with it can be relayed. In the meantime, as you may be contemplating just how hydrogen can play a role at your operation, it’s clear that the electrolyser choice is an important place to begin.

Mining Business Africa | January - February 2023 9

Spill Control - Environmental Protection, Health and Safety in Mining

Sound Spill Control, Compliant Operations

Accidental releases of oils and chemicals make up a large number of pollution incidents that occur each year on mining sites. Fortunately, many spillages can be prevented. However, everyone on site must know how to control a spill to minimise its impact. Thus, bearing this in mind, Spill Doctor advises mining companies on the best practice in spill control.

An increase in the spillage of hazardous oils and chemicals on sites is inevitable as mining companies are pulling out all the stops in endeavouring to increase productivity. However, the biggest concern is whether or not they are well-equipped to manage the safety risks that this poses to both their employees and the environment.

The reality is that sound spill control cannot be overlooked.

The obligation of legislation

In all countries, various pieces of legislation obligate mining companies and other industries to ensure that they adopt and rigorously implement measures to mitigate the impact of their activities on their employees and the environment. And South Africa is no exception.

In particular, South Africa’s Occupational Health and Safety Act of 1993, requires employers to bring about and maintain, as far

as reasonably practicable, a work environment that is safe and without risk to the health of the workers. Specific to mining companies, the Mine Health and Safety Act (MHSA) applies.

Raising awareness

Given the potential increase in spillage of flammable liquids, Spill Doctor has intensified its drive to raise awareness amongst mining companies about the best practice in spill control (the management of flammable liquids). In this way, the company aims to enable mining companies to achieve compliance with legislation.

Extensive experience and relevant products

As environmental, health and safety specialists, Spill Doctor is eager to address the unique needs of clientele in the mining sector. This is based on extensive experience accumulated from years of effectively addressing complex spill management challenges for clientele drawn from diverse industries.

Spill Doctor’s team are thoroughly versed in the management of stubborn flammable chemicals. This is above and beyond the company’s wide range of relevant products.

What is most noteworthy for clientele about Spill Doctor’s range of internationally compliant products is that it is handy, Kelvin Murphy, Head of the Team at Spill Doctor, states. “Our flammable cabinets, safety cans, plunger cans, oily waste cans, drums and dispensing equipment offer FM-approved products along with an exclusive 10-year limited warranty. The products support clients in the mining sector to reduce the risk of fire, employee injury and environmental damage caused by incorrect storage of flammable liquids. Generally, our products include “everything the client needs” to store, distribute and remove flammable liquids in a safe and legally-compliant manner. We have worked extensively to obtain exclusive

12 Mining Business Africa | January - February 2023 FEATURE

Some of Spill Doctor’s range of internationally compliant products

FEATURE

distribution rights in Africa for internationally recognised brands in the health, safety and environmental fields. “

To cater for the unique needs of clientele, Spill Doctor has products specific to occupational health and safety, as well as environmental management.

• Occupational health and safety

Spill Doctor’s extensive range of occupational health and safety products includes spill pallets, non-combustible flammable stores, flammable safety cabinets, eyewash stations and combination showers.

Spill doctor’s range of environmental products for spill control, spill containment and spill kits offer compliance with local environmental regulations and a five-year guarantee on polyethene products.

• Environmental management

Spill Doctor has tailor-made its environmental products cognisant of the importance of sound environmental impact mitigation practices in mining environments. “Although our main focus is on minimising risks and prevention of incidents, we understand that environmental spills do occur. That is why we are the distributors of a full bio-remedial range of products to repair damaged areas,“ Murphy says, guaranteeing that the products meet both local and international regulations regarding the safe storage, distribution and general usage of flammable and ignitable liquids.

Proactive Spill control

As a provider of storage solutions that assist clients in safely storing dangerous substances, Spill Doctor is unrelenting in urging mining companies to follow the best practice in spill control, as lapses can be very costly.“The incorrect storage of flammable and hazardous liquids can cause fire, injury and environmental damage. And so, mining companies must assume a proactive - not a reactive mindsetwhen it comes to spill control,“ Murphy explains, highlighting the following areas as vital in proactive spill control: Pollution Prevention Spill Control, Good Storage Practices, Flammable and Combustible Liquids and Flammable or Explosive Limits.

• Pollution prevention spill control - avoid environmental harm

Spills spread very quickly and can cause damage to the environment, and fines and clean-up costs can be expensive. Thus, to avoid damage at the site, it is important to know where all spill kits are and how to use them. This should be coupled with an annual spill response drill to ensure knowledge of plans and how to use clean-up equipment.

• Good storage practices

To ensure proper storage, mining sites should ensure that they have a spill kit on-site and train their staff on how to use it. The site should store liquids within secondary containment, store substances away from stormwater drains and waterways, ensure storage of substances away from high-traffic areas, and make sure all storage containers are labelled. Also, it is good practice to check regularly - before and after any rain for any spillages or any flooding and ensure that the containers are not damaged or have any leaks.

• Flammable and Combustible Liquids

Generally speaking, flammable liquids will ignite (catch on fire) and burn easily at normal working temperatures. Likewise, combustible liquids can burn at temperatures that are usually above working temperatures.

Under the Workplace Hazardous Materials Information System (WHMIS), flammable liquids have a flashpoint below 37.8°C (100°F) and combustible liquids have a flashpoint at or above 37.8°C (100°F) and below 93.3°C (200°F). These may include thinners, cleaners, adhesives, paints, waxes and polishes which are present in almost every workplace.

However, sometimes more than one flashpoint is reported for a chemical since testing methods and purity of the liquid tested may vary. In some instances, flammable and combustible liquids such as gasoline, with a flashpoint of -40°C (-40°F); and phenol, with a flashpoint of 79°C (175°F) can mix their vapours and the air begins to burn.

• Flammable or Explosive Limits

The lower flammable limit or lower explosive limit (LFL or LEL) of gasoline is 1.4 per cent; the upper flammable limit or upper explosive limit (UFL or UEL) is 7.6 per cent. This makes gasoline flammable when it is in the air at levels between 1.4 and 7.6 percent. It should therefore be noted that a concentration of gasoline vapour in air below 1.4 percent is too “lean” to burn and gasoline vapour levels above 7.6 percent are too “rich” to burn. Flammable limits, like flashpoints, however, are intended as guides not as fine lines between safe and unsafe.

Most common flammable and combustible liquids have auto-ignition temperatures in the range of 300°C (572°F) to 550°C (1022°F), while some have very low auto-ignition temperatures. When solvent-evaporating ovens are heated to temperatures above the autoignition temperature of the solvents used, it results in serious fire hazards, as a flammable liquid can burn very fast and give off a lot of heat and often clouds of thick, black, toxic smoke. Also, spray mists of flammable and combustible liquids in the air may burn at any temperature if an ignition source is present.

The vapours of flammable and combustible liquids are usually invisible, which makes them difficult to detect unless special instruments are used. Most flammable and combustible liquids flow easily and a small spill can cover a large area of the workbench or floor.

Burning liquids can flow under doors, downstairs and even into neighbouring buildings, spreading fire widely. Materials like wood, cardboard and cloth can easily absorb flammable and combustible liquids; and even after a spill has been cleaned up, a dangerous amount of liquid could remain in surrounding materials or clothing, giving off hazardous vapours.

These can also cause health problems depending on the specific material and route of exposure, for instance through breathing the vapour, eye or skin contact, and swallowing. Some of these liquids are corrosive, and many undergo dangerous chemical reactions if they contact incompatible chemicals such as oxidizing materials when stored improperly.

It is therefore important to check the Material Safety Data Sheet and the supplier’s labels on the containers.

On the whole, Spill Doctor assures mining companies that it is well-resourced to meet their needs in the health, safety and environmental fields.“As a leader in internationally compliant products, we will find the unsullied product for your storage, distribution and removal of flammable liquids in a safe and legally-compliant manner,“ Murphy wraps up.

For more information, visit www. spilldoctor.co.za

14 Mining Business Africa | January - February 2023

Vac-Cent’s Vacuum pumps and compressors

Pumped up for service excellence

Vac-Cent Services, local manufacturers of vacuum pumps and compressors, is eager to serve clientele diligently as they embark on projects in 2023. While its name has become synonymous with Gardner Denver Nash Liquid Ring Vacuum Pumps and Compressors, Vac-Cent offers a broad range of product brands and solutions.

High-profile forums present an opportunity for Vac-Cent Services (Pty) Ltd to inform decision makers in the African mining sector about the relevance of its company’s pump and compressor solutions to their respective projects. And The 2023 Investing in Mining Indaba is not an exception. This is not least coming at a time when the mood in the global mining sector is bullish, illustrated by increase in projects being rolled out.

Eager to exceed expectations

As they have diligently done every year, the company’s team of competent Technical Sales Team vow that they are eager to exceed expectations in the provision of vacuum pump requirements and compressors to clientele in mining. While the market is awash with different brands of pumps and compressors, the Team believes that experience makes Vac-cent’s relevant products stand out. “In fact, what we offer is not just products, but a solution,“ states the company’s Team head declares.

Tapping into experience

As a seasoned player, Vac-cent has been on the mining equipment block for a while. It was formed in 1987. And since then, it has perfected the knack of providing appropriate liquid ring pumps, compressors and associated equipment to clientele in the mining sector. The team hopes to tap into the huge depth of experience to address the respective equipment needs of clientele in mining.

Broad range of equipment brands

Vac-cent has a broad range of equipment brands

that include vacuum pumps, compressors and channel blowers and accessories.

• Vacuum pumps

Under licence, Vac-cent manufactures the world-acclaimed Gardner Denver NASH Liquid ring vacuum pumps. In addition, the company distributes and imports Rotary & Carbon vane vacuum pumps. Vac-Cent also manufactures two different sizes of vessel-mounted filtrate pumps. These pumps are available in SG Iron and Stainless steel or a combination of the two materials. Both types of pumps are 100 per cent manufactured locally.

Enabling equipment availability

It is unfortunate that the business of mining equipment is never short of customers who get short changed by suppliers. This is a big concern to Vac-cent. However, the company recognises the importance of the availability of equipment in mining operations. That is why it offers services to ensure equipment uptime such as on-site Liquid ring vacuum pump Performance testing and Vacuum surveys.

To ensure the uptime of equipment, Vac-cent offers service exchange pumps and corrosion protection.

• Service Exchange Pumps

Vac-cent offers Service Exchange units available to help clients minimise downtime while ensuring quality repair and replacement of their pumps.

• Corrosion Protection

The company provides various coatings for new

or repaired pumps or compressors for harsh environments. The types of coatings used may include ceramic coatings, cladding, glass flake coatings or stainless steel body wear rings and head face plates. The correct protection is selected when given the circumstances in the area.

Quality Assurance

Vac-cent recognises the importance of the availability of equipment in mining operations. That is why it offers services to the subequatorial Africa and Indian Ocean islands region that ensure equipment uptime such as on-site Liquid ring vacuum pump Performance testing and Vacuum surveys.

To ensure the uptime of equipment, Vac-cent offers service exchange pumps and corrosion protection.

The Head of the Technical sales team at Vac-cent affirms that Vac-cent adheres to the highest quality standards in the provision of solutions to the clientele. Its commitment has been recognised by the ISO 9001:2010 seal of approval for quality, an accreditation it has held since 1994.

Opportunities in mining projects

Vac-cent’s is eyeing opportunities to participate in African mining projects in 2023 and beyond. The Team Head says that its competent Technical Sales Team are on hand to handle any needs of clientele of any scale in the areas relating to installations and improvements to current processes.“We are pumped up for service excellence.“

Repair & Service

Technical Sales & Support

Service

Mining Business Africa | January - February 2023 15

FEATURE N A S H L I Q U I D R I N G V A C U U M P U M P S V a c - C e n t S e r v i c e s h a s b e e n m a n u f a c t u r i n g

A S H L

u i d R

c

P u

p s a n d

N

i q

i n g V a

u u m

m

C o m p r e s s o r s 1 0 0 % L o c a l l y s i n c e 1 9 8 7

A

V a c - C e n t S e r v i c e s o f f e r t h e e n t i r e N

S H

a n g e W e m a k e i t t o s u i t y o u r p r o c e s s ! V A C - C E N T S E R V I C E S ( P T Y ) L T D O F F E R S T H E F O L L O W I N G : New

Vacuum

V a c u u m P u m p a n d C o m p r e s s o r r

Engineered

Pump Sets

H E A D O F F I C E 1 2 4 S N A P P E R R O A D W A D E V I L L E T : + 2 7 1 1 8 2 7 1 5 3 6 I N F O @ V A C C E N T . C O . Z A W W W . V A C C E N T . C O . Z A

Exchange Vacuum Pumps On Site Performance Testing

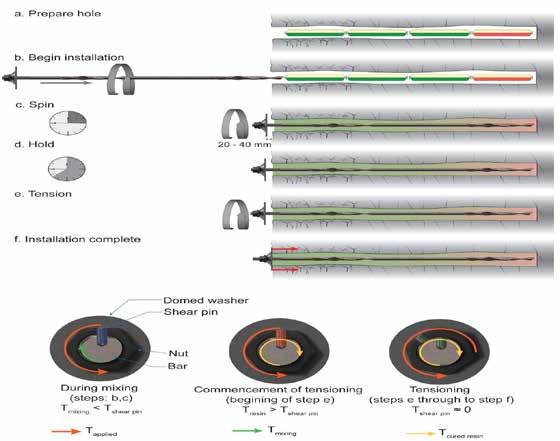

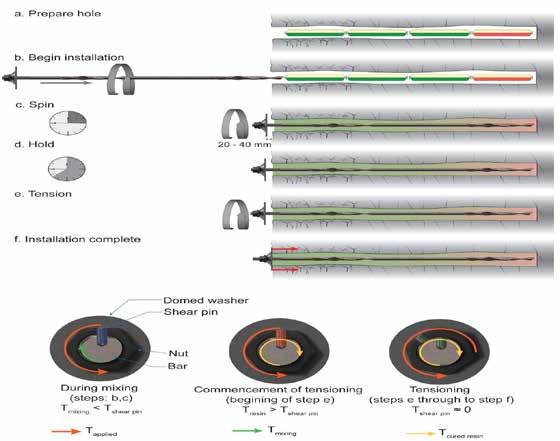

Ground support for deep-level mining operations

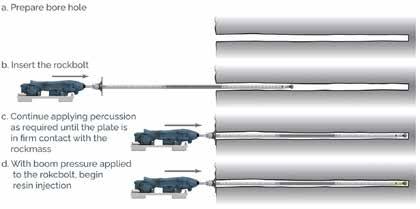

A practical alternative to resin grouted rockbolting

Ground support systems have been used for over a century in mines across the world. The use of rockbolts has been documented as early as the late 19th century, where reinforced steel was used to stabilise rock walls in mines.

The technology has evolved, as mine operations tunnel deeper, requiring new support for different ground conditions. In such environments, effective ground support equipment is required to reinforce the rock around excavated tunnels, to facilitate safer and more efficient operations, and successful installation is critical to ensuring the capacity of the rock reinforcement element.

The traditional installation of resin grouted rockbolts requires a support hole to be pre-drilled followed by the installation of the resin capsule. The rockbolt is then spun into the grout, mixing the resin completely.

Challenges when installing resin capsule grouted rockbolt

Epiroc Ground Support has extensive experience

with testing the integrity of resin grouting solutions in varied environments. The research has noted the typical challenges facing miners installing resin capsule grouted rockbolts as follows:

• Ensuring a quality installation, the diameter of the support hole, the rate of rotation, rate of insertion and spin time must be monitored to ensure an effective installation. Mistakes can prove costly, as any deviation from the manufacturers specifications may result in a reduction of resin strength, and failure of the support system.

• In highly stressed, poor ground conditions, the presence of fractures, shear features and altered rock can lead to unravelling of the support hole, resulting in blockages preventing the installation of the resin capsules. Efficiency is then affected, as support holes may need to be re-drilled, leading to oversized holes, increased installation times and poor installation quality.

• Lastly, the resin within the capsules is fixed, therefore variations in hole diameter and

resin losses into voids may cause a failure to achieve a full column bond.

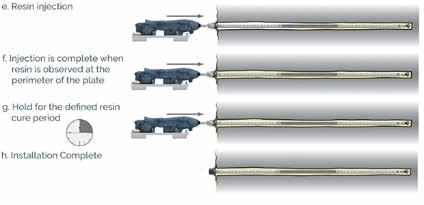

The solution

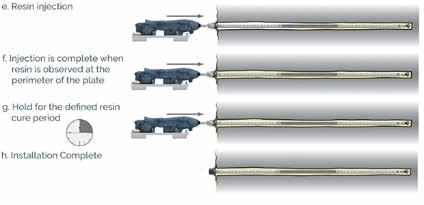

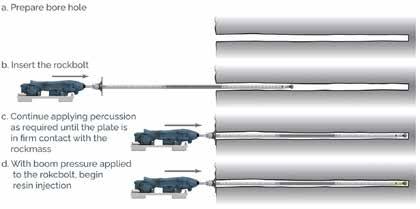

Having observed the challenges that impact the integrity of the rock reinforcement system when using resin capsule grouted rockbolts, the experts at Weber Mining and Tunnelling and Epiroc partnered up to develop a high strength polyurea silicate resin, Potentia® Thixo. Potentia® Thixo, in combination with the high performance Boltec and post-grouted rockbolts developed by Epiroc, offers an effective solution to overcome the challenges faced with capsule resin installation.

Achieve full column

This installation process is more resilient to changes in the rock mass. When the rockbolt is inserted into the predrilled bore hole and the pumpable resin is then injected through the rockbolt filling the bore hole from the back to the collar. Post grouting ensures that a full column is achieved as resin is injected through the bolt until

16 Mining Business Africa | January - February 2023 FEATURE

resin is observed at the perimeter of the plate. The thixotropic nature of the resin ensures the resin remains in the borehole whilst rapidly curing to strengths in excess of 35 MPa.

Easy to transpor t

Additionally, the resin and catalyst, which are the two components of Potentia® Thixo resin are stored and transported in IBC.

Shelf life

The 2-year shelf life is not affected by changes in temperature, which simplify logistics and supply chain.

Quality

The quality of the mixed Potentia® Thixo is auditable and assured as the two components are mixed in a 1:1 ratio by a digitally controlled pumping system on the Boltec. This ensures the quality of the resin mixture is established prior to injection into the rockbolt and remains consistent through varying ground conditions. With a setting time that can be tailored from 35 seconds for bolting applications to 900 seconds for cable bolting applications.

Mining Business Africa | January - February 2023 17

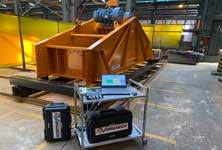

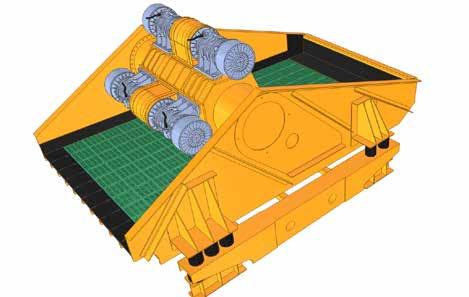

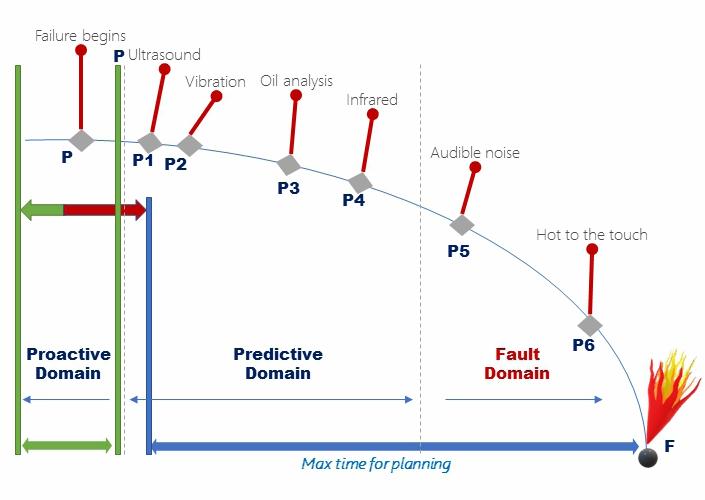

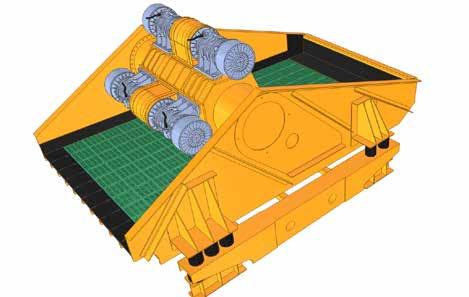

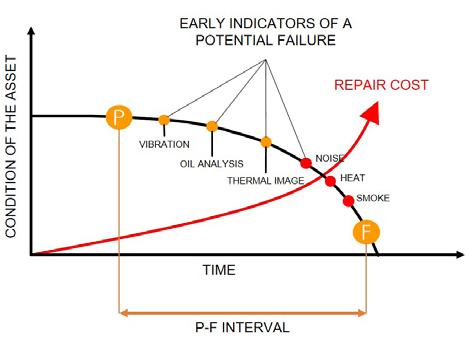

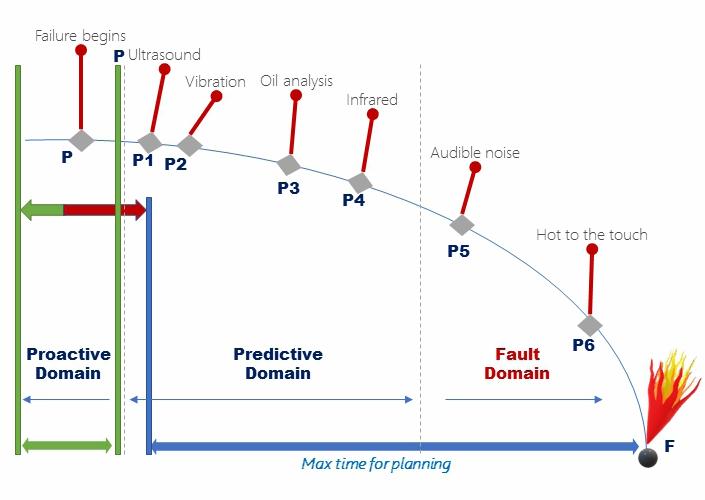

Continuous Vibrating Equipment Condition Monitoring Up-to-the-minute Equipment Condition Monitoring

“Vibrasure”, offered by Vibramech, enables effective real-time monitoring & predictive maintenance of vibrating mineral processing equipment, ensuring dependability through this critical phase of production. By utilising Vibrasure’s online continuous condition monitoring system, one can ensure that the vibrating equipment performs at its optimal best, consistently & reliably.

Healthy vibrating equipment forms part of the lifeblood of the mineral processing industry worldwide. That is why Vibramech understands that no one in this industry tolerates unexpected failures of equipment, especially when one is pulling out all the stops in increasing production. And when a failure does occur, the loss of productivity and the attendant loss of revenue, or irreparable damage to equipment, or at worst causing injuries, are totally unacceptable. So, how can this be minimised or preferably avoided?

Vibrasure

In recognising the critical importance of ensuring the productivity (uptime) of vibrating equipment, Vibramech introduced Vibrasure in 2021.

David Massey, Vibramech’s MD, is thrilled to offer this solution: “Vibrasure was introduced to enable mining companies to effectively manage and maintain the health of their vibrating equipment, resulting in maximum uptime. We all know what a crucial role vibrating equipment plays within a mineral processing plant. Therefore, Vibrasure essentially allows

for early fault detection, diagnosis and analysis, and for the formulation of a solution prior to a serious breakdown. Also, Vibrasure perfectly complements Vibramech’s extensive footprint of industry-acclaimed vibrating equipment.”

Online condition monitoring

Vibrasure is an online condition monitoring system that enables real-time continuous vibration monitoring of, and feedback on, the equipment’s operational performance parameters at any given time, such as vibrating frequency, stroke, angle of motion and

18 Mining Business Africa | January - February 2023

FEATURE

Vibrasure’s online condition monitoring system in use

temperatures, and it will detect and provide early warnings against machine faults.

Why Vibrasure?

Vibrasure is recommended by Vibramech, an expert with over 45 years experience in the design, manufacture and maintenance of vibrating equipment.

Vibramech is Southern Africa’s leading Original Equipment Manufacturer of a wide range of vibrating mineral processing equipment, with over 10 000 pieces of equipment currently in operation, worldwide. In scrutinising the needs and developments in mineral processing with a vested interest, Vibramech is eager to impart its extensive know-how in the maintenance of its vibrating equipment to all of its clients, and the best way of doing so is with the implementation of Vibrasure.

Although there is a variety of online vibrating equipment monitoring products available in the open market, David Massey emphasises that Vibrasure’s platform and functionality are derived from the company’s specialist expertise in the supply and maintenance of vibrating equipment.

In this regard, Vibrasure through predictive maintenance will put mining companies in a wellplaced position to cope with, and even mitigate the risk of breakdowns. The use of structural and bearing sensors that are designed with the latest technology, and which are IP69K rated to withstand the harshest of conditions, coupled with long-life integral batteries, ensures that the end user receives all of the valuable information needed to maintain effective production.

The system, in particular, reports key parameters to a cloud-based platform, where the data can be trended over time to optimize the performance of vibrating equipment. “We offer as an added option, that the data from the cloud-based platform could alert our engineers of serious deviations in equipment performance, giving our clients the additional comfort of knowing that they will be forewarned of possible breakdowns.”, Massey outlines.

High-quality assurance standards

Underlying the creation process of Vibrasure, was Vibramech’s own high-quality design and manufacturing standards in the provision of its equipment. It is worth highlighting that the company’s quality control & assurance programmes make provision for, inter alia, full 3D vibration analysis to be conducted on all equipment prior to release. “Our design practice makes use of finite element analysis and strain gauge analysis to prove structural integrity, with detailed attention paid to wear protection and commonality of components to maximise productivity and minimise spare part inventories.”, says Massey, adding that this enables Vibramech to set a benchmark for the life of the equipment, that exceeds the industry standards.

As with all of the equipment that Vibramech offers, its Vibrasure product is equally robust and has a long life expectancy. Overall, the

introduction of Vibrasure has received a hugely positive response from the industry, and this underscores Vibramech’s commitment to providing quality, reliable, and robust vibrating equipment.

Through Vibrasure, Vibramech offers an additional safety net enabling its clients to depend on its equipment, by advancing reliability & endurance over the long term.

Market leader in vibrating mineral processing equipment

Vibramech supplies its equipment primarily to mining and mineral processing industries across the globe. Particularly, it has extensive experience in gold, diamond, coal, iron ore, manganese, platinum, chrome, nickel, uranium, copper, mineral sands and aggregate minerals.

Since its establishment, Vibramech has installed 10,000 pieces of equipment in mines worldwide, but predominantly in South Africa. This has positioned the company as a market leader in the supply of vibrating mineral processing equipment to both project houses and mines in South Africa and the region. “We believe our reputation is richly deserved. It is a consequence of continuous technological innovation over four decades and this has cemented our status as an OEM of dependable equipment, which stands out for its robustness and reliability throughout the world.”

Visit Vibramech’s website at www.vibramechglobal.com for an overview of how Vibramech could assist with your current and future mineral processing requirements.

Mining Business Africa | January - February 2023 19

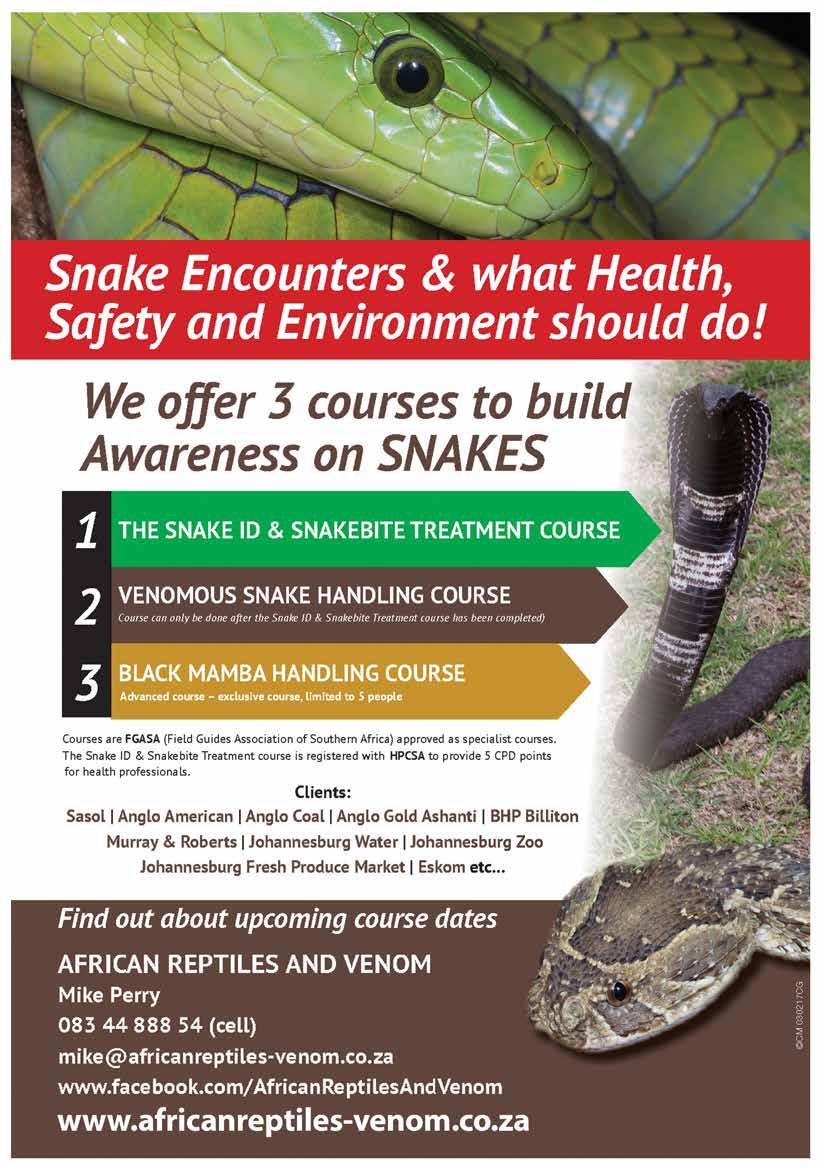

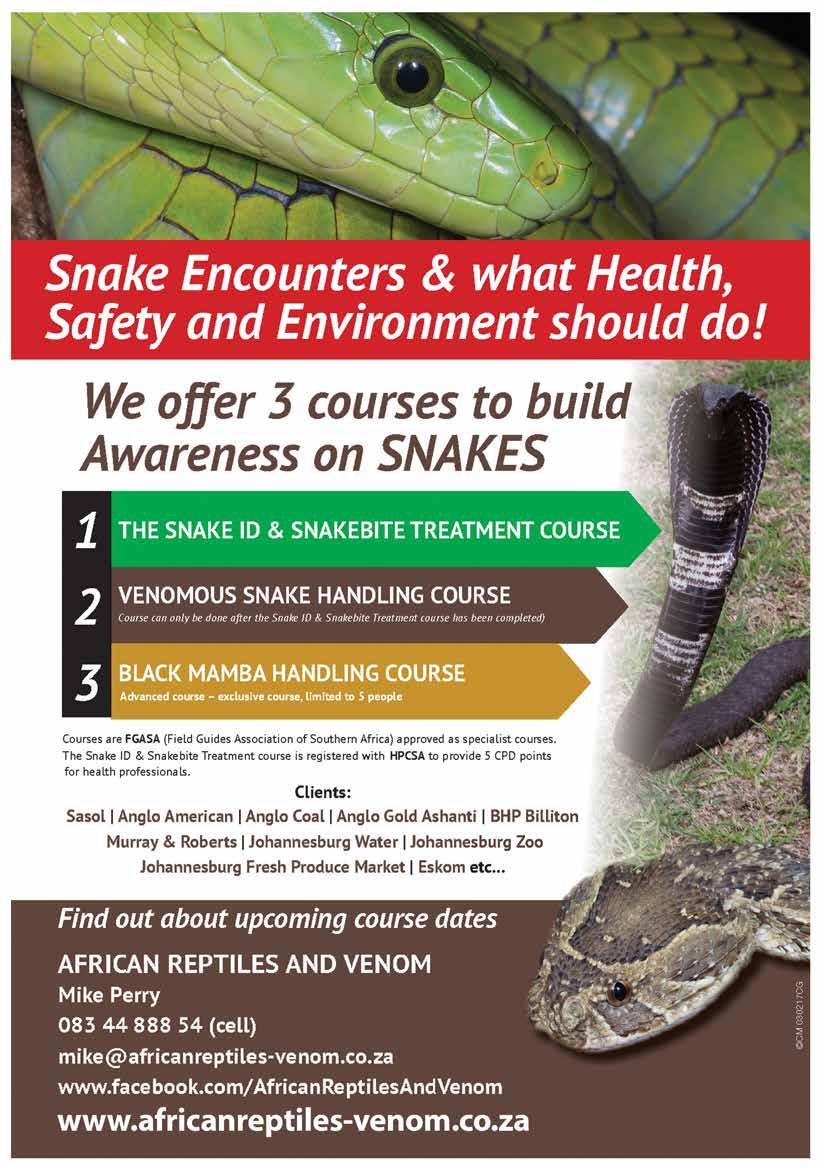

Turnkey snake awareness for exploration & mining projects

Containing the risk of snake bites and attacks

Wherever there are mining activities, snakes pose a huge threat to the safety of employees. So far, improved awareness is the most potent weapon in mitigating the risk they pose. However, African Reptiles & Venom recommends that only a credible service provider must be engaged to conduct snake awareness courses among employees at all times.

called ‘low-hanging fruits. In a nutshell, as far as health and safety issues go, it is better to err on the side of caution with snake encounters or bites.

This is the viewpoint of Mike Perry, the Managing Company Owner of African Reptiles & Venom. As an old hand in snake awareness, he is tirelessly advocating for an attitude change towards containing risks from snakes mineworkers face. African Reptiles & Venom is a highly esteemed provider of relevant turnkey snake awareness solutions to companies in the mining and other sectors.

Raising awareness

Based on the company’s extensive know-how, Perry is keen to raise awareness about the risk mining companies face, highlighting the level of prevalence at mineral exploration and mine development and operation phases. This is above and beyond the relevance of the company’s turnkey snake awareness solutions. Prevalence

of snakes

Usually, there is a high prevalence of snakes both at mineral exploration and mine development and operation phases.

• Mineral exploration phase

Legislation – the Mine Health and Safety (MHSA) and Occupational Health and Safety Act (OHSA) - obligates mining companies to leave no stone unturned in the quest to achieve compliance. Unfortunately, the reality is that some mining companies tend to be selective - unwittingly or not - in containing identified safety risks.

The overlooked safety risk

Conspicuously, the primary focus is on so-called ‘low-hanging fruits‘ like fire accidents and fallat-height, just to cite a few. And in the course of this, inherent risks from snake encounters or bites that equally merit similar attention are ignored or underestimated.

Actually, wherever mining companies have operations, the risk of snake encounters or bites should be regarded as high at all times. It is rational to approach the risk of snake encounters or bites in a similar manner they do with so-

The location of the mine during the exploration phase determines the level of prevalenceWhether or not it is close to green fields during the exploration period by drilling companies and the number of people involved in the drilling. Typically, while the drilling takes place the snake population will remain intact, and will not be disturbed by this process.

• Mine development and operation

Once minerals have been discovered and planning has been completed, the steps that follow are: clearing the bush, and erecting buildings and infrastructure like the plant, mine shafts, clinics and hospitals, living quarters and dining areas. Due to these activities, there are a lot of encounters with snakes - depending on where the mine is situated.

After completion, as soon as there is an influx of people onto a mining site, there are large quantities of waste food disposed of, which will attract rodents by the thousands. This in

20 Mining Business Africa | January - February 2023

FEATURE

African Reptiles & Venom has a hands-on approach to snake awareness.

turn will attract an influx of snakes. Usually, the following areas in operating mines are prone to high snake presence (risks) - living quarters, dining areas, storage facilities or any areas that border virgin bush next to falling dams.

On a different note, seasons also need to be taken into consideration as a factor in the prevalence of snake populations - hot, dry, cold, or wet. These will influence activity.

Turnkey snake awareness

There may be several techniques – if any - to manage the risk of the presence of snakes in mining environments. Arguably, while others may work, if at all, African Reptiles & Venom has identified raising employee awareness as the most effective way to manage the risks. And so, it has devised mining-specific turnkey snake awareness solutions segmented into the following areas: Snake identification, First Aid for snakebites, Snake bite treatment and Handling technique.

While the company’s snake awareness solutions are segmented, Perry stresses that they can be customised to suit the needs of clientele. This is because every mine may have unique risks they face from potential snake attacks. For this reason, the company ensures that a mine is provided with a solution suitable to its challenge, as Perry demonstrates: “Upon reaching the mine, we will do a walk around assessment, advise Health and Safety officials of existing and potential risks, and make recommendations that are appropriate to the mine.“

The service providers‘ competence

In no doubt, African Reptiles & Venom bends over backwards in its commitment to delivering relevant solutions to client expectations. That is why the company is concerned about how mining companies approach procurement of snake awareness – a critical area in mine health and safety.

Perry tells mining companies to separate the wheat from the chaff among companies claiming to provide snake awareness solutions. “There should be no cutting corners in the mitigation of risks from snakes, as shortcuts can put the lives of employees at risk.“

By and large, he advises mining companies to consider the following when looking for a competent service provider:

• The company should have a credible history and involvement with snakes;

• The organisation should be under someone in the company who is accredited as an expert in the field;

• It is important to get a summary of the layout of the course to see the quality; and

• Do not use price as the sole determinant of procurement decisions. Nine times out of ten the cheap price is a red flag. The rule of thumb is: The cheaper the course, the lower the quality and the higher the risks of incidents.

African Reptiles & Venom’s credibility

Currently, mining companies are embarking on greenfield and brownfield projects in areas where there is likely to be a huge prevalence of snakes. So, Perry warrants there should be no question about the African Reptiles & Venom’s credibility. Noticing increasing potential risk to employees from snake attacks and bites, he says the company is keen to leave no stone unturned in imparting its know-how in snake awareness.

The scope of African Reptiles & Venom’s turnkey snake awareness course

The course starts with a theoretical session with content which consists of the below. A PowerPoint presentation is done by Mike Perry with images explaining all the necessary information, covering:

1. Snake Awareness

2. How to identify snakes

3. Dangerous snakes found in their specific regions

4. Prevention of snakebite

5. Snakebite syndromes

6. First Aid for snakebite treatment

7. Medical snakebite treatment

8. Recognition and treatment of allergic reactions

Introduction to safe snake handling

• Rules to apply for snake handling without causing medical emergencies

• Safe snake handling equipment, First Aid for snakebite kits and how to use it.

• How to catch different snakes illustrated using slides and video.

22 Mining Business Africa | January - February 2023

FEATURE

Only a credible service provider must be engaged to conduct snake awareness courses

Environmental Impairment Liability (EIL) Insurance for mining operations

Insuring against third-party environmental impairment liabilities

Are mining companies well-equipped to handle third-party environmental impairment liabilities? James Brice, Head of Environmental at iTOO Special Risks, outlines to Mining Brief Africa critical steps mining companies must take.

South African legislation requires that all local mining operations must ensure they make financial provisions to guarantee the availability of sufficient funds to undertake rehabilitation and remediation of the adverse environmental impacts of mining activities, not only during the life of the mine, but also at closure.

“Current regulations around mine rehabilitation and closure guarantees mean that mines are obligated to close their operations responsibly so that they can return the land to its prior use,” explains James Brice, Head of Environmental at iTOO Special Risks.

“This is based on the theory behind mining, which states that while you can take what you want from underground, you must return the land to the landowner who can resume activities on it as before the valuable component was extracted.”

Typically, mining rehabilitation regulations focus on first-party obligations, such as when a mine has a pit, tailings dam or discard dump, which is operated and owned by the mine on its premises and that causes some change to the land.

“Mines are generally good at following regulations. They will often bring in a consultant

to quantify these obligations and then they follow the regulations around having a financial guarantee to cater for planned or unplanned closures,” says Brice.

“This means that even if the commodity price drops and a mine goes bankrupt, at least they have this reserve financial provision parked away to be able to do good by the environment and return the land to the landowner. This is called a financial guarantee.”

Focus on first-party liabilities

He explains that while insurance companies provide financial guarantees to mining

Mining Business Africa | January - February 2023 23

FEATURE

Acid mining drainage as a result of mining

operations, these typically cover first-party liabilities and the cost of doing good for the environment. Usually, these are risks are wellknown and quantified.

“The problem is that often mining operations forget to worry about third-party liabilities, such as those stemming from neighbours, communities and downstream water users who may have been affected by the mine,” says Brice.

“And because there’s been a focus on firstparty rehabilitation, there has been little in the way of allocating financial provisions to cater for affected third parties, with about 95% of South African mines not having any financial provisions or insurance coverage for these financial liabilities.”

All too often, mining companies tend to extend their mining rehabilitation guarantees to cover things like dust affecting the surrounding community, which can increase the risk of cancer risks, or acid mine drainage that can sterilise downstream wetlands, rivers and dams.

“We have seen some high-profile mining incidents lately, such as acid mine drainage spills at Tugela in March and Zululand Anthracite Collieries a year ago and the tailings dam collapse at Jagersfontein in September. None of those companies were insured against this type of risk,” says Brice.

In this event, he explains, companies are forced to take a hit on their balance sheets,

which in turn impacts their shareholders, so many are reluctant to pay out. Yet, mines must do the right thing.

“The solution lies in having the right insurance product for the right type of risk. The problem with extending financial guarantees is that there are certain regulations around what this money can be used for.

“It has to be liquid, so in most cases, this money cannot be invested in long-term projects and will at best earn money market returns of 7-9%. Normally, a Chief Financial Officer would be looking for a 25-30% return on equity.”

Brice says that instead of investing anywhere between R20 million and R150 million into their financial guarantees to cater for something that may not happen, it would be much more efficient for mining companies to take up an insurance product that does not have to be self-funded.

Transferring third-party risk

“With a product like iTOO’s MineSafe, mines pay a premium and transfer their third-party risks to our balance sheet. The premium payable is similar to that for a financial guarantee, but companies do not have to self-capitalise. They can use this money for operational growth and expansion instead.”

Brice says that it is also important for mining companies to keep in mind that especially with dust or water pollution, the contaminants would have spread over many years, if not decades,

potentially affecting many more potential claimants, leaving mines exposed to a class action.

Mines are in a precarious position and iTOO is the only insurer that can place cover for gradual pollution liability, including historic and existing pollution. This is a comprehensive policy that covers seven insuring clauses for peril: emergency response; legal defence; third-party bodily injury; third-party business interruption; ecological restoration; clean-up; and ongoing monitoring and reporting to a public liaison.

Brice notes that when choosing suitable environment impairment liability insurance, mining companies should determine whether the insurer has the technical ability to give them credit for the environmental rehabilitation work that has already been done.

“We believe in rewarding clients for doing the right thing in terms of what is good for the planet. As iTOO, we expend a lot of money at our own costs and risks to do risk assessments, interview management and study the monitoring data,” says Brice.

“This is a lengthy process, but it is important to fully understand the risk and be sure that we design a product that fits the actual requirements and to also give the client credit for what they are doing correctly.”

24 Mining Business Africa | January - February 2023

FEATURE Optimize Your Roughing, Cleaning & Scavenging with Eriez Magnetic Elements & Tanks • Hybrid Rare Earth-Ceramic elements produce greater recovery in cobbing and roughing stages • Cleaning and finishing magnetic elements improve selective separation Eriez.com | 814.835.6000 Greater Recovery Better Grade with Eriez Deep Field 3,500 Gauss Magnetic Wet Drums Eriez_WetDrum_HalfPg_MMAfrica9_22.qxp_Layout 1 9/29/22 3:02 PM Page 1

Optimise your mine’s balance sheet exposure with iTOO’s MineSafe product - the only cover that ensures you’re covered for both historic and existing mining liabilities. Speak to your broker to get cover or visit www.itoo.co.za iTOO Special Risks (Pty) Ltd (Reg. No: 2016/281463/07) is an authorised Financial Services Provider (FSP No. 47230) underwritten by the Hollard Insurance Company Limited (Reg. No: 1952/003004/06), a licensed non-life insurer and an authorised Financial Services Provider. Think Expert. Think iTOO

FEATURE

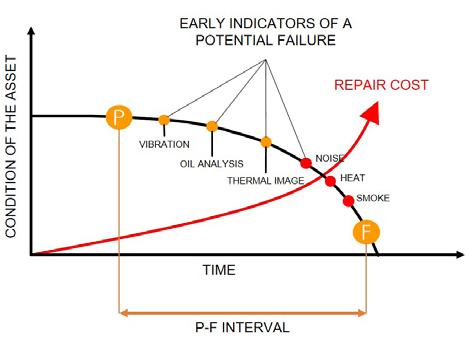

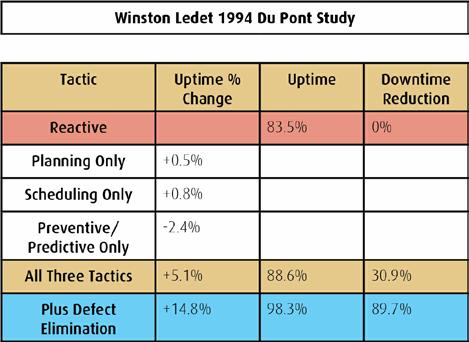

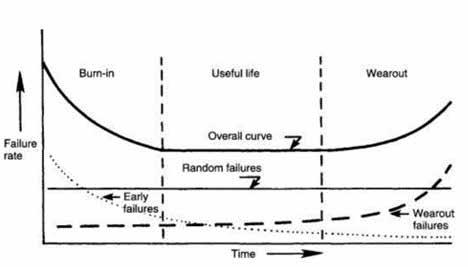

A new perspective on modern-day maintenance

By Raymond T. Chizu, Business Developer, WearCheck Zimbabwe

LearCheck provides thousands of customers each year with world-class condition monitoring (CM) services, which have been proven time and again to save time and money for companies by identifying potential machine failure before it happens and remedying the problem.

However, in our line of work as condition monitoring (CM) specialists, we still do come across customers who have everything to gain by using the CM techniques we offer but, unfortunately, they don’t see the benefits to be gained. No matter how hard we try to convince them, they stubbornly continue to refuse help.

In this article, I’m going to try to get to the bottom of this standoff and hopefully we’ll find ways to engage every maintenance organisation to employ condition monitoring techniques whenever it is economically practical to do so.

I’m going to start with the definition of maintenance and then go through the changes to which maintenance has been subjected over the years. This knowledge, I believe, will help us understand some conflicting behavioural patterns exhibited by some maintenance personnel.

The verb ‘maintain’ gives the idea of preserving/keeping a certain status or specification. In engineering terms, maintenance is the execution of those tasks that ensure that the asset/plant owner achieves design and performance specifications of their asset/plant in order to meet their business objectives.

Let’s take a look at the internal combustion engine as an example. For the engine to operate at optimum level, the lubrication system must be at a certain pressure and temperature, the cooling system at a certain temperature, and the fuel system and the compression should be at a certain pressure. In this case, maintenance activities will include regular testing, adjusting, lubricating and cleaning.

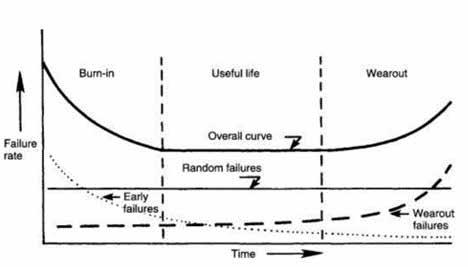

The focus of maintenance should be upon the ‘wellbeing’ of the plant/asset – when the task is to ‘fix it’, then maintenance has failed its basic mission, quite possibly through no fault of its own. With the definition out of the way, let’s look at how maintenance has changed during the course of time. Modern maintenance has gone through three generations:

First generation

Its inception is traced back to the beginning of

the industrial revolution right up to about the First World War. Maintenance then was premised on the ‘Fix It When It Broke’ philosophy, better known as Breakdown Maintenance (BdM). This was ideal at that time because machinery was quite rugged, overdesigned, relatively slow running, and the instrumentation and control systems were very basic. Production demands where not overly severe and downtime wasn’t usually a critical issue. Most of the labour was manual. Even up to this day there are still some machines in existence that were manufactured around that time, which are still running as good

as the day they were made.

Second generation

From the Second World War to the end of 1950s - with the rebuilding of industry after the war, a more competitive marketplace emerged, and along with this, an increasing intolerance of downtime. The cost of labour increased significantly, and this led to more and more mechanisation and automation. Machinery was of lighter construction and ran at higher speeds. These machines wore out more rapidly and were seen as less reliable (perhaps it was because they were being utilised more fully).