Starting at $659.00 (100W system with cables and I/O breakout)

LS Electric servo systems provide the most requested features — setup wizards, auto tuning, built-in indexers and more — in an extremely cost-effective package:

• 17 standard servo systems from 100W to 7.5kW

• 230 VAC & 460 VAC three-phase input power (230 VAC single-phase up to 2.2kW)

• Low and medium inertia models

• 19-bit absolute encoders available on certain models

• Control via high-speed pulse train, analog speed or torque signal, or internal indexing

• Use with AutomationDirect CLICK, Do-more BRX, or Productivity Series PLCs; or any other host controller

• FREE setup software with Auto-Tuning (AND built-in o-scope functionality)

• Fully digital with up to 1kHz velocity loop response

• 30-day money-back guarantee

• Two-year warranty

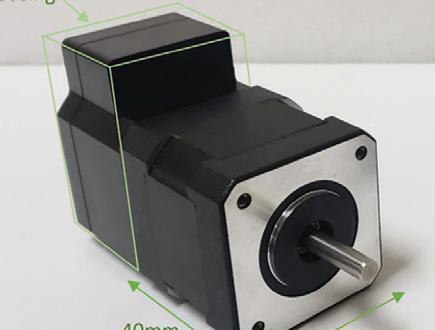

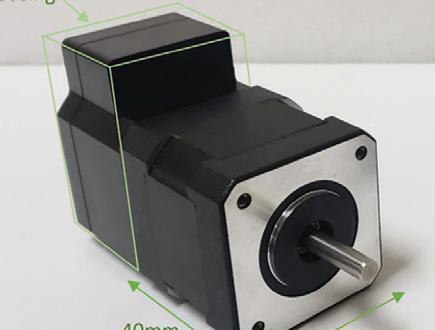

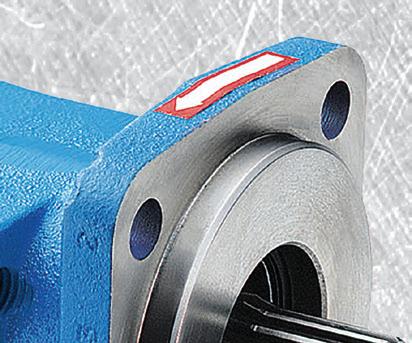

LS Electric® MSS Series

Inline Planetary Gearboxes

Starting at $288.00 (96200004)

Perfectly matched LS Electric gearboxes offer easy mounting to the servo motor. Use these gearboxes to increase the available torque or to solve inertia mismatch problems.

• 5:1, 10:1 and 20:1* gearbox models exactly matched to each motor size

• Increase the available output torque by 5x, 10x or 20x*

• Full motor output torque allowed for all pairings

• Reflected inertia of the load is reduced by the square of the reduction ratio!

• Mounting hardware included *15:1 max ratio for 7.5kW system

Engineering leaders are not immune to that constant management mantra of motivate, motivate, motivate. In fact, some managers I’ve known seem to do little more than try to motivate others, with flowery speeches and too-long-toread emails ending in statements like “This is going to be THE YEAR!!!”

But in his book, What to say when you talk to yourself, Shad Helmstetter, Ph.D., goes against the grain in many ways and doesn’t really believe that this kind of motivation works at all. He posits that this sort of encouragement, whether coming from a boss or a coach or a fitness instructor, is always very short-lived, as the energy depends on the person trying to motivate. Thus, it has to be repeated often (and endlessly) — which sure sounds like a recipe for tediousness and boredom.

According to Helmstetter, the real key is encouraging people to motivate themselves. Employees want to believe that they can do more individually and achieve more as a team. But the negative self-talk that we all tend to participate in weighs us down and reprograms our subconscious to truly believe those things. Think of all the things we say to ourselves in our heads (and sometimes to others). “I can’t get the hang of this new system,” “I won’t ever get anything out of these conferences,” “I don’t get along with anyone in that department” ... all of these harmful and negative types of self-talk really do become self-fulfilling prophecies — and they serve to hold back individuals.

Many of us short-change ourselves with the negative way we speak to ourselves. Think about the things you tell yourself, especially concerning tasks that you wrestle with at work. It’s not about having a Pollyanna attitude that isn’t realistic, but it’s more about refocusing and reframing how you see challenging tasks.

If you have coworkers who seem to struggle with their outlook on things, perhaps a casual chat about self-talk (and how you’ve successfully incorporated it into your life), might be a good topic for a one-on-one lunch with them sometime soon. And maybe a copy of Helmstetter’s excellent book, after you’ve read it yourself, might be the thing that really helps that coworker to motivate themself — for years to come. DW

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

Paul J. Heney - VP, Editorial Director pheney@wtwhmedia.com

If you’ve driven on U.S. roads in the last few years or so, chances are pretty good that at one time or another you’ve experienced the scourge of blinding headlights.

For the longest time I suspected it was only me that was bothered, that I was simply getting older and my eyes more sensitive to light at night time. But as it turns out, I’m not alone in thinking the lights are too damn bright, as the steady stream of news articles over the past few years and adjacent commentary make clear.

The fact is that headlights have gotten progressively better over the last century. The earliest headlights in the late 19th century when the first automobiles were introduced were lanterns powered by oil or gas. These earliest headlights illuminated the road better than nothing, but they were not that powerful.

Shortly thereafter came electric headlights, which were a marginal improvement. What really revolutionized lighting was the invention of the sealedbeam headlight shortly before WWII. This produced a more focused beam of light that helped illuminate the road better

than anything that had come before. Improvements continued with halogen lighting in the later part of the 20th century, followed by the introduction of xenon-based high intensity discharge (HID) technology and most recently LED headlights. However, that’s just part of the story. The other key factor involves vehicle design itself. As the U.S. automobile market has become saturated with ever bigger vehicle sizes, the roads are now filled with larger SUVs and trucks, all of which have front ends that sit higher o the ground. Consequently, the headlight placement in these vehicles is also higher up, and thus more of the intensity of the light is at eye-level of other drivers on the road, leading to the blinding headlight phenomenon.

But wait, there’s still more! Perhaps the most important factor involves an old federal law on automobile headlights in the U.S. The law states that all vehicles in the U.S. must have both a low-beam and a high-beam headlight. The problem is that the solution to excessively bright headlights lies in so-called adaptive headlight technology,

which uses a single beam that’s software controlled to respond to the surroundings, making the beam stronger and more intense when it needs to be and dialing it back in other instances.

Thus, while adaptive headlight technology has been standard on newer vehicles across the world, it has not been legal to build it into vehicles in the U.S. because of the law requiring two separate beams. The good news is that thanks to the Infrastructure Bill passed last year, there is a provision that rescinds the two-beam requirement and opens the door for adaptive headlight technology to be incorporated in vehicles in the U.S.

The lesson here may be how many di erent factors play a role in solving a problem. From the design of the headlights (including the software used in the new adaptive technology) to the vehicle design itself, to the role of government regulations and the need to revisit them as our technology continues to evolve; it takes a great amount of coordination to get it all right in the end. And save our collective eyeballs. DW

Dim

Follow the whole team on twitter @DesignWorld

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Lisa Eitel leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor

Miles Budimir mbudimir@wtwhmedia.com @dw_motion

Senior Editor

Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com @WTWH_Rachael

Associate Editor

Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

CREATIVE SERVICES

VP, Creative Services

Mark Rook mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director

Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer

Allison Washko awashko@wtwhmedia.com @wtwh_allison

Graphic Designer

Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director,

Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer

Melissa Annand mannand@wtwhmedia.com

Software Engineer David Bozentka dbozentka@wtwhmedia.com

DIGITAL MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

EVENTS

Events Manager Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Videographer

Garrett McCafferty gmccafferty@wtwhmedia.com

Videographer

Kara Singleton ksingleton@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist

Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager

Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

FINANCE

Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

Interpower® accessory power strips (APS) incorporate one AC power inlet with multiple AC power outlets allowing multiple device integration. Customizable options include push button, rocker, or guarded circuit breakers, connector locks, and fuses. Voltages range from 10A-15A/100240VAC. Common APS configurations are 10 or 12 Sheet F outlets or an 8 Sheet F and 4 Sheet J outlet combination. In-stock accessory power strips ship the same day!

• World-class customer service 7 a.m. to 6 p.m.

• Value-added services including lengths, colors, & packaging

• No minimum order or dollar requirements

®

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–6 p.m. CST

Order Online! www.interpower.com

®

Machine Vision is becoming much more critical in automation applications, especially where robotics is involved. GigE Vision is a global standard communication protocol that has been adopted by machine vision camera manufacturers. Illustration courtesy of Antaira

As robots are increasingly used in various material handling processes, more users are finding that the addition of vision to these robots is enhancing and expanding their capabilities. Vision Guided Robot (VGR) technology has advanced beyond the early days of programmable transfer machines thanks to advances in 2D and 3D cameras, visual servo control, embedded Ethernet networks, and increasingly more sophisticated software including AI.

Advances in RGBD cameras — composed of a standard RGB camera and a depth sensor — have received considerable attention lately because of their ability to quickly acquire 3D models of the environment and to estimate the camera pose in a low-cost way.

Empowering a robot to “see” allows it to precisely and consistently differentiate, pick, sort, move, weld or assemble

various parts no matter their complexity. For instance, a multiple-step manual welding task on an automobile assembly line might take ten “blind” robots to perform since each part must be mounted in place before every weld. However, this same multi-step welding process can be done with a single VGR, since its camera can precisely align the different parts in place without human assistance.

Flexibility is another huge benefit of VGRs. As with a machine vision system on an assembly line, a VGR uses intelligent processing to give it instructions. A slight alteration to the code allows the same robot to perform entirely different tasks, i.e., switching between products and batch runs, with no mechanical adjustments.

And then there is safety. With VGRs, factories can significantly reduce the risk of on-site accidents. A vision-

guided forklift inside a warehouse, for example, will sense obstructions along its pre-programmed paths and avoid contact with people or objects while precisely selecting items o pallets to meet customer orders. At Amazon, for instance, robotic material handling “cobots” (collaborative robots) safely work directly alongside humans. The Amazon Sparrow robot uses vision and a robotic arm and is able to pick up a new item and deposit it on a metal chute every three seconds, handling more than 1,000 items per hour.

To add vision to a robot, one or more cameras are needed. One is mounted on the robotic arm, serving as the machine’s eye. Other cameras are installed in strategic locations in the working cell to capture more visual data. Adding these static cameras will compensate for the limitations of the arm-mounted camera. Careful attention must be given to ensure the camera and lens has the proper resolution, frame rate, and depth-of-

field required for the application at an acceptable cost. Low-cost GigE Vision cameras are preferred since they use standardized, o -the-shelf Ethernet cables and components, while eliminating the need for frame grabbers.

A major trend today is to purchase VGRs already equipped with a vision system supplied by the robot manufacturer. This translates into faster adaptation into a production line, lower costs, and more responsive technical support from a single manufacturer.

Whether the vision system is installed by the end-user or the OEM, it will require an industrial Ethernet switch to create an embedded Ethernet network within the robot. Ethernet allows the individual robot parts to communicate with each other and is suitable for VGRs because Ethernet can handle image data. High port-count Industrial Gigabit Ethernet switches for robots can make the networking of Ethernet nodes uncomplicated.

Space inside a robot is always a limiting factor. A compact DIN-rail design

Interpower® accessory power strips (APS) incorporate one AC power inlet with multiple AC power outlets allowing multiple device integration. Customizable options include push button, rocker, or guarded circuit breakers, connector locks, and fuses. Voltages range from 10A-15A/100240VAC. Common APS configurations are 10 or 12 Sheet F outlets or an 8 Sheet F and 4 Sheet J outlet combination. In-stock accessory power strips ship the same day!

• World-class customer service 7 a.m. to 6 p.m.

• Value-added services including lengths, colors, & packaging

• No minimum order or dollar requirements

Antaira

fiber Ethernet switches are IP67 rated for harsh industrial environments including resistance to moisture, dust, vibration, and shock.

| courtesy of Antaira

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–6 p.m. CST

Ethernet switch can easily fit next to a power supply, contactor, or relay. Power over Ethernet (PoE, PoE+, PoE++) is available on most to uncomplicate the connection of cameras and other components. In addition to multiple Gigabit Ethernet ports, industrial switches also o er SFP slots for fiber optic connections. Fiber is impervious to electronic noise, so the SFP slots may be useful in running long-distance communications between the robot and a remote higher-level controller. While the industrial switch’s remaining Ethernet ports are able to collect data from various components in the robotic cell.

These Ethernet switches are built industrial-grade to withstand harsh manufacturing environments. They

are housed in sturdy IP30-rated metal cases and can be trusted to handle high levels of vibration, electronic interference, and wide temperature swings. DW

Antaira Technologies

www.antaira.com

(Source: Hanry Martel, Field Application Engineer, Antaira Technologies)

Fortress Technology’s supermarket-spec metal detector is sensitive enough to adapt to the fine oil and sugar tolerances on the honey roast nut line.

Most snack producers opt for gravity metal detectors. With 15 Fortress Vertex snack inspection systems integrated with multi-head weighers in its Liverpool factory, global nut supplier Trigon Snacks is no exception. Yet, for its latest coated honey roast nut production line, the sustainable nut specialist selected a custom linear Stealth metal detector with an innovative retractable conveyor reject system.

Processing 7,000 tons of nuts annually from its British Retail Consortium A-grade and RSPO certified facility, Trigon Snacks supplies a wide range of nuts and snacks to the licensed trade, retailers, and food service operators. Marketed under its own brands, and retailer own-labels, for its new honey roasted nuts line the company commissioned a highly sensitive conveyorstyle metal detection concept to ensure compliance with global retailer and regulatory standards.

Stringent retailer COPs specified that as “naked nuts” the new honeycoated range must be inspected for metal contaminants prior to own-label packaging. Additionally, Trigon required a supermarket spec metal detector that was sensitive enough to adapt to the fine oil and sugar tolerances and meet the regulatory requirements of every geographical market they are sold in.

For logistical reasons, a small-footprint, wide-head Fortress Stealth metal detector engineered to inspect the fried, dried, and seasoned nuts on a

conveyor before entering the chute and falling into the one-ton sacks, was the most viable and accessible option.

Screening 32 tons of honey roasted nuts daily, space limitations were a key driver to the design, said the company’s lead engineer Mark Grieve. “Being located on a mezzanine floor, we commissioned a wide head yet highly sensitive metal detector with a specially adapted linear conveyor system measuring just 40 cm wide.”

Factoring in the conveying and reject system was critical to guarantee reliable operation and avoid false readings. Given the tight footprint, a custom solution was the best way to ensure that metal detector performance was not compromised.

The low-profile nuts combined with the inspection speed meant that a kicker would be incompatible. It is also virtually impossible to isolate and divert contaminated products with

naked products. With insufficient space to accommodate a flap style reject, Fortress instead engineered a clever and efficient retracting band conveyor and reject mechanism.

The metal detector which sits at the front of the conveyor calculates precisely how long any contaminated nuts will take to reach the end of the conveyor band, communicating via the metal detector control system. The belt then smoothly retracts back on a sliding rail rolling the rejected nuts into the dedicated bin located beneath the conveyor, resuming its inspection position in just seconds.

To-date, Trigon reports zero false rejects on its new honey roasted nut line, upholding the company’s longstanding sustainable, ethical, and traceable principles. Despite admitting he was slightly apprehensive by the compact dimensions of the entire system, Mark corroborates that it has already proved itself to be a reliable and easy to use machine.

Hourly manual tests are the only reported source of daily waste. The lead engineer estimates this to be less than 0.05% of the total production, well below the food manufacturing average which on some lines can reach double figures.

From a sensitivity perspective, the metal detector is exceeding expectations identifying ferrous and non-ferrous particles smaller than 1.0 mm and stainless-steel particles under 1.5 mm. This level of sensitivity can be attributed to the low-profile metal detector head.

Affirming the importance of customizing the aperture, Eric Garr, North America Regional Sales Manager commented: “Aperture size is critical to optimal operation. Customizing the aperture around the product being inspected is one way to ensure the metal detector will perform to optimal levels. Additionally, integrating a conveyor system, fully assembled and checked, is another failsafe way of making sure a producers’ stringent sensitivity requirements are not compromised.” DW

Fortress Technology | www.fortresstechnology.com

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

Until now, many users have shied away from the e ort required to introduce autonomous guided vehicles (AGVs) and autonomous mobile robots (AMRs) into their processes. Project durations are often several months, and the areas of application in the facility must be equipped with marking strips, reflectors or mirrors. Afterwards, specialists must manually train the mobile units to e ectively navigate their environment.

With the ROKIT Locator software, mobile robots can independently determine their position. Users no longer need expert knowledge or additional infrastructure to commission a mobile robot. Locator allows mobile robots to determine their position and orientation in any environment, simplifying the automation of intralogistics tasks in industry and trade. Locator is compatible with various industrial controllers and laser sensors on the market and is suitable for mobile units of all sizes and drive types.

Locator enables the robots to evaluate the signals from a laser sensor in the vehicle and convert them into coordinates in space.

No permanently installed aids, such as markers or reflectors, are required for orientation and position determination. Users only need one click to start up the system and familiarize the unit with its surroundings in a onetime orientation trip. An intuitive user interface based on 3D technology is provided for this purpose. The software maps an initially unknown environment and automatically creates a map.

Locator stores this map on the vehicle itself, or optionally on an on-site server component. If several mobile units are used, they all access this map. Afterwards, immediate localization is possible without initial knowledge.

If a vehicle detects a change in the environment, such as when setting up a new storage location, it sends this information to the server,

which automatically updates the map accordingly and sends it to all the mobile units in the fleet. Mobile units purchased subsequently with the Locator take over the server data when they are put into operation and can drive off immediately.

The Locator can be used in various vehicle types, industries, and applications. The software is independent of the hardware used by a vehicle manufacturer. As an encapsulated function block, it fits into numerous control systems and supports a wide range of laser sensors, including safety lasers. DW

Bosch Rexroth

www.boschrexroth.com/en/ us/products/product-groups/ assembly-technology/topics/amr/

Turn your design challenges into next-generation, marketleading medical devices with our extensive manufacturing capabilities and engineering expertise. We have facilities in Fremont, CA and Santa Ana Sonora Mexico.

HydraForce, Tan Delta Systems, and Elevāt have developed a way to eliminate the most common causes of o -highway machine downtime. The solution is composed of di erent parts, a mobile machine telematics solution from Elevāt that seamlessly incorporates with manifold assemblies using HydraForce cartridge valves and Tan Delta oil conditioning sensors.

The integrated solution provides a centralized portal along with email and text alerts providing fleet operators with remote monitoring, control, and optimization capabilities for field-deployed assets.

The solution supports remote diagnostics, predictive maintenance, live updates, and proactive telematics reports. The interface is easy-to-use with fast access to data. It reports in a clear format so issues can be addressed before they impact machine operation.

The Tan Delta oil conditioning sensors provide operators with machine operational data and deliver custom alerts to inform the operator or owner when hydraulic fluids require maintenance. The combination of an electronic controller architecture with telematics provides multiple benefits to users, including real-time data and ongoing alerts of oil conditions. The reported information will prevent excessive wear of hydraulic components and catastrophic failures that can occur

when machines are in operation, thus, leading to increased productivity and reductions in machine downtimes and maintenance costs.

Through accurate monitoring of oil health, maintenance scheduling can also be optimized as equipment is serviced only when required, and operators can rest assured that any unexpected changes in the oil condition will be immediately detected and reported. This can also extend the operational life of equipment and overall machine health, as optimal oil conditions prevent unnecessary wear and tear. DW

Elevāt | elevat-iot.com

Four new high resolution, high repeatability XY Alignment Stages, the AU200120x120 Alignment Stages, feature 120 mm (4.724 in.) of travel in both the X and Y axes. These low profile 87 mm (3.425 in.) high XY stages, have a 188 mm x 188 mm (7.401 in. x 7.401 in.) open aperture. Easy integration of tooling and fixtures is facilitated through a precision series of threaded mounting holes.

The AU200-120x120-01 XY Stage is stepper motor driven, featuring a resolution of two microns when using a 10 micro-steps-per-step micro-stepper motor driver and one micron repeatability. The AU200-120x120-02 Stage is supplied with threephase brushless servo motors and quadrature incremental encoders, and AU200120x120-03 has DC servo motors with quadrature incremental encoders. The two closed loop servo motor options o er greater resolution, repeatability, positional accuracy, higher travel speeds, and greater throughput. The AU200-120x120-04 has the knobs on the stepper motors replaced with quadrature incremental encoders for position verification.

Typical applications include: alignment, inspection, testing, scanning, laser drilling, machining, semiconductor handling, sampling, assembly, and optical applications in industrial, medical and research applications. The AU200-120x120 alignment stages can be ordered as a complete plug-and-play system with compatible motion controllers with PC interface, joystick and keypad. DW OES

This series of waveguide frequency multipliers addresses 5G, test-and-measurement, mobile and satellite communications, radar systems, research and development, and weather and earth observation applications.

The series of in-stock, waveguide frequency multipliers covers 26.5 GHz to 110 GHz, including popular mmWave waveguide bands: Ka, U, V, E and W.

The waveguide frequency multipliers are engineered with GaAs and GaN MMIC semiconductor technology for lower conversion loss. They provide output power from +10 dBm to +20 dBm. They feature DC voltages from +6 Vdc to +15 Vdc and allow input frequency multiplication ranges from two times to six times the output.

The frequency multipliers also feature female SMA connectors and offer efficient performance in a small package.

The new line ensures reliable, all-weather performance. They operate at temperatures from -40 to 176 degrees Fahrenheit, under exposure to 95% relative humidity, and up to an altitude of 10,000 feet. They are tough and compact with military-grade, gold-plated aluminum waveguide package designs. DW

Fairview

The food industry is booming — especially the fresh food business on the Internet. More and more fresh and processed foods, as well as ready-to-eat meals and convenience products, are being ordered online and must be produced and packaged with speed, e ciency, and tight control of hygienic conditions to maintain food quality.

This calls for ensuring that food and packaging technology is as agile and responsive as the front-end digital Internet technology driving growth. Automation and robot technology are, therefore, increasingly being used in logistics and warehousing for food and packaging companies. However, adding this technology only makes sense if the degree of automation can be adapted to the specific requirements of the company, enables a strong return on investment (ROI), and supports growth strategies.

The newest generation of smart, open automation platforms, like Bosch Rexroth’s ctrlX AUTOMATION, combine machine control, the IT world, and the Internet of Things (IoT), using fundamentally new, open software architecture. The ctrlX AUTOMATION platform includes advanced controller and drive hardware components, stateof-the-art software technologies for implementing IoT, artificial intelligence, security, and connectivity solutions for all PLC and motion tasks.

The platform’s foundation is its Linux realtime operating system, which is considered the most stable and secure of its kind. Thanks to the container technology of the operating system, all functions and applications can be mapped with separate apps and combined as desired.

The ctrlX CORE controller system used in CIMCORP’s robot solutions combines compact size and lighter weight with Linuxbased multicore technology that breaks down the boundaries between embedded system platforms and drive-based technology.

Platforms like ctrlX AUTOMATION are taking a new, smartphone-inspired approach to programming automation functions. Just as society now uses apps to individually adapt smartphones to a user’s needs, automation OEMs and end-users can now do the same.

O ering both versatility and scalability, the ctrlX DRIVE system covers both simple single-axis applications and complex multi-axis machine systems, enabling faster implementation of coste ective individual solutions that grow as requirements evolve.

Machine builders can choose apps from the automation platform provider and use apps from third-party suppliers or even apps created by OEMs or end-users in the food processing and packaging industry, thereby expanding the range of options supported to meet specific and unique operational needs. Existing code can also be integrated as an app for real-time and non-real-time applications. There is a free choice of programming language; C++, Python, Java, and many more are supported.

How fresh food automatically has a longer shelf life

A leading supplier of e-commerce intralogistics technologies has upgraded its robotic technology to leverage multiple ctrlX AUTOMATION capabilities. CIMCOROP

MCORP’s robotic material handling systems for food processing and logistics operations, like this gantry robot, use the advanced capabilities of the ctrlX AUTOMATION platform to accelerate processes in order processing and shipping.

GROUP has developed robotic solutions for order processing and warehousing in the food and beverage, retail, e-commerce, fast-moving consumer goods (FMCG), and postal services sectors. With CIMCORP’s robot solutions, companies from the food industry and other segments can specify and accelerate processes in order processing and shipping. For fresh food, this means that perishable products reach the market faster and have a longer shelf life, leading to less food waste.

The company was an early partner and adopter of the ctrlX AUTOMATION platform and helped actively shape a specific solution for intralogistics. The core component here is the gantry robot used in various applications in their operations.

According to Jani Tuomola, Head of Machine Development at CIMCORP, the company already had a close business relationship with Bosch Rexroth, so they were well prepared to transition to ctrlX AUTOMATION.

“Bosch Rexroth had previously supplied control systems to CIMCORP, and we were always very happy with the quality of the products and the service and support o ered,” he said.

CIMCORP realized multiple benefits from using the new platform as the automation controller for its gantry robot. The control cabinet space was reduced by 30%, and the arrangement of the control cabinet components was optimized to save space compared to the previous system.

The open control system for integrating IoT and security enabled CIMCORP to implement easy connections to logistics software. CIMCORP also uses the ctrlX CORE control platform, which is integrated into the drive in a space-saving manner, and the ctrlX MOTION software for Cartesian robots DW

Bosch Rexroth

www.boschrexroth.com

Whether you need a variable-speed AC, a high starting-torque PMDC, or a zero-maintenance brushless DC gearmotor, we’ll help you find the right solution for your application.

.

If you’ve got questions, we’ll find the right solution.

Cryogenic measurements of the multi-channel RF cable Cri/oFlex-3. Flexible cables are terminated with SMA connectors. The measurements were performed at frigid liquid nitrogen temperatures.

The Background Imaging of Cosmic Extragalactic Polarization Project (BICEP) has been ongoing for several years and is now seeking solutions for a hardware upgrade to its telescope’s sensitivity as the project digs deeper into the cosmos to learn more about the origins of the universe. That’s why Delft Circuits, a maker of cryogenic cabling solutions, will join the BICEP project in Antarctica, supporting NASA’s Jet Propulsion Laboratory (JPL) at CalTech and other project partners.

A team at JPL is pioneering a new way to scale the number of detectors on the high optical frequency receivers

The multi-channel Cri/ oFlex-3 cables with vacuum feedthrough. The connector blocks and the flexible part of the cables are shown. Similar cables are being used in the BICEP project.

of the telescope array. The team at the Jet Propulsion Lab has determined that advanced cables made by Delft Circuits will be installed in the telescope’s cryostat as part of its new camera. The team will also replace the telescope’s sensors with new thermal kinetic inductance detectors (TKIDs), which are superconductive detectors leveraging the properties of quantum mechanics. The infrastructure requirements of TKIDs, and the techniques used to measure them, are extremely similar to what is required in a quantum system. Once the new equipment is installed, the experiment will determine if the

frequency multiplexing enabled by this new technology will allow for the necessary scaling of the telescope’s detectors to greater sensitivities.

“I was very happy to find Delft Circuits, which was able to meet our stringent requirements for transmitting microwave frequencies, flexibility, and cryogenic performance in a single cable. This makes my work considerably easier,” said Lorenzo Minutolo of Caltech and NASA’s Jet Propulsion Laboratory a liate. “The cables perform well and remain flexible at any temperature. This is beneficial for us because they make it much simpler to

A team at JPL is pioneering a new way to scale the number of detectors on the high optical frequency receivers of the telescope array.

assemble the hardware we need for this Antarctica upgrade. We can therefore devote more time and resources to other aspects of the experiment, which helps us reach our objectives faster and at a reduced expense.”

The Cri/oFlex multi-channel and RF cryogenic I/O cables, which will be used inside the BICEP Array telescope, are durable and flexible rather than rigid like the alternative. This provides users the opportunity to design and test multiple prototypes in their process while reusing the cables over and over for each di erent iteration. This had not been possible before, thus providing significant value for users in terms of cost and setup time.

“Our product is the only cable capable of providing microwave

transmission capability in a flexible cable that performs in cryogenic conditions. We are very pleased that scientists of this caliber see value in this 3-in-1 combination we’ve developed,” said Kiefer Vermeulen, Research and Development Engineer at Delft Circuits. “Users can now accomplish what used to be weeks of setup work in only a couple of hours. We consider it an important milestone in our development to be trusted by the famous BICEP project, in conjunction with so many distinguished scientists and research partners. This is a proud day for our team.”

background using transition edge sensors. TKIDs will replace those sensors, and their performance will be validated by comparing their results with existing maps produced using the old technology. If successful, the experiment will validate TKIDs as a viable technology for future missions.

Del Circuits del -circuits.com

The BICEP Array telescope looks for traces of gravitational waves in the cosmic microwave

The BICEP Array telescope looks for traces of gravitational waves in the cosmic microwave

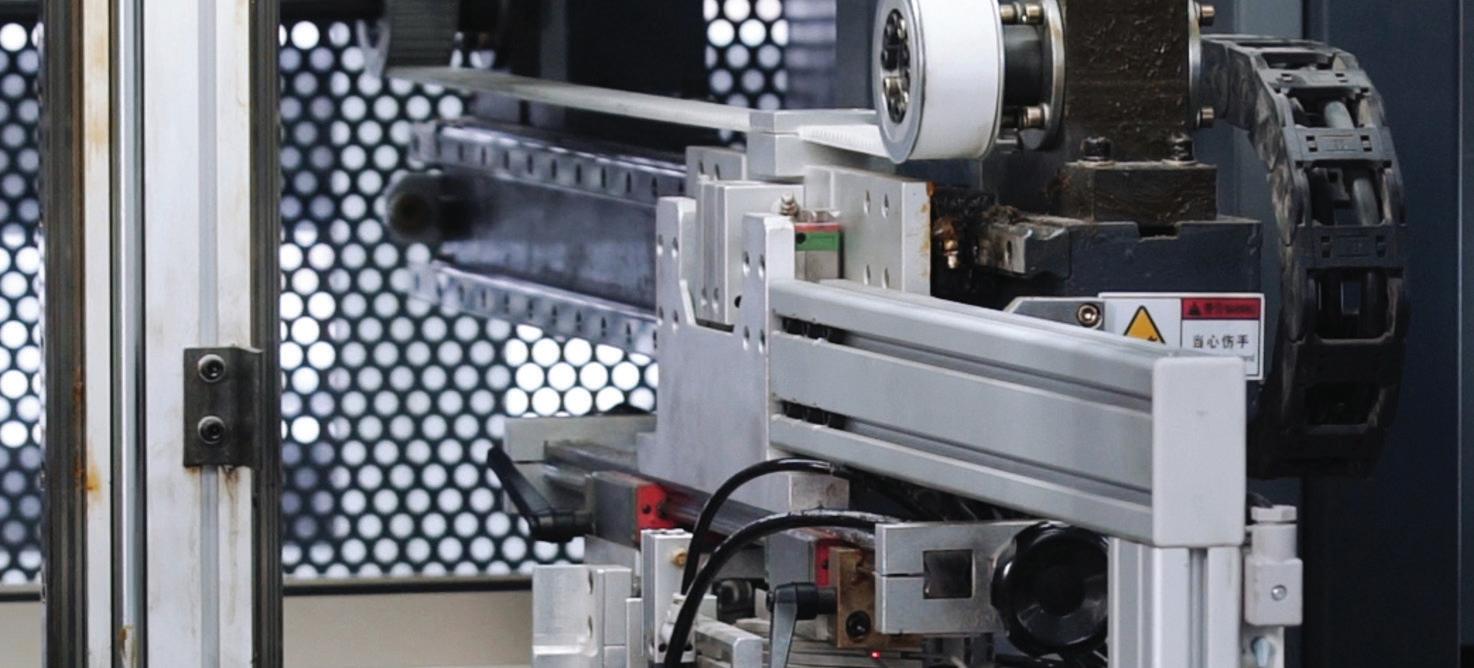

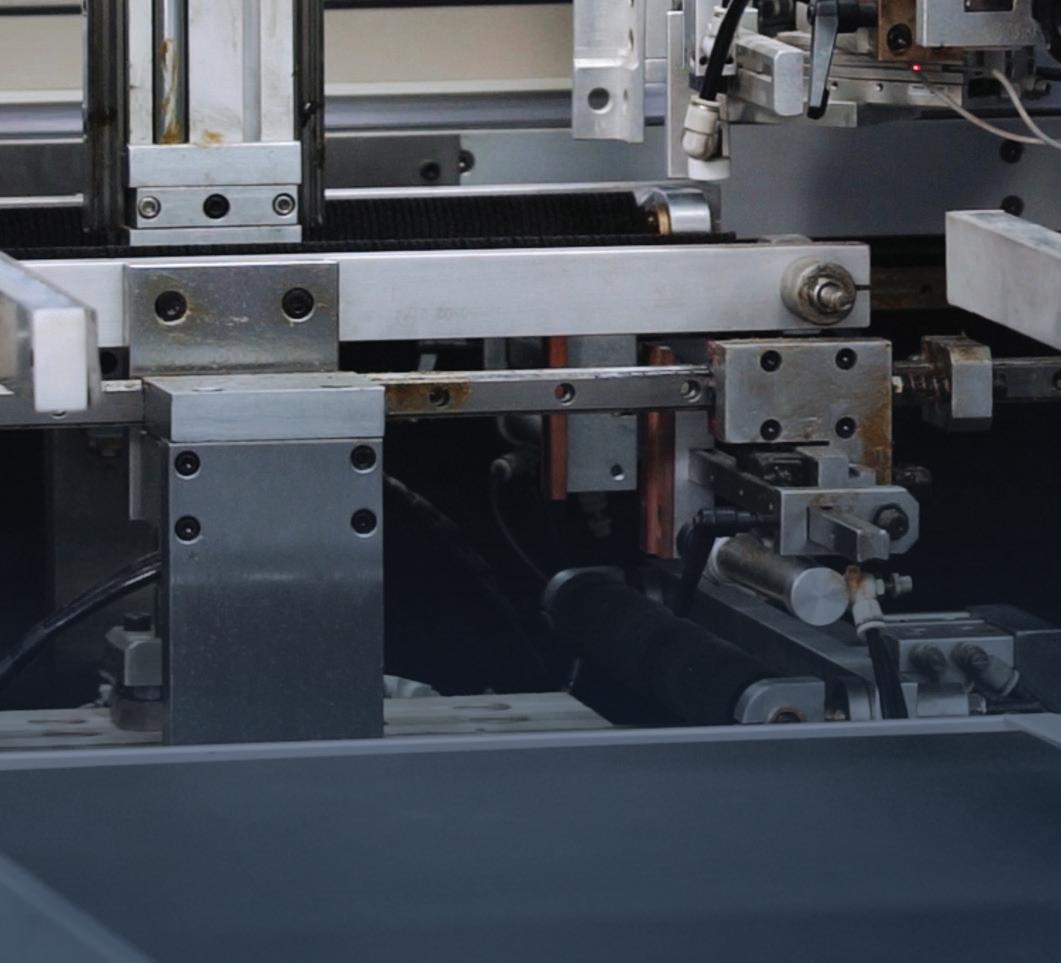

Trenton is a manufacturing facility focusing mainly on manufacturing parts for machines and tractors used for agriculture.

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

Trenton is a manufacturing facility focusing mainly on manufacturing parts for machines and tractors used for agriculture. Trenton’s Giordano Cecchini explained the benefit of having VICIVISION measuring machine involved in the process of producing parts at their facility.

“A company like Trenton, with its good reputation, is a real landmark in this area. Most of the manufacturing is done in-house, and we take care of many di erent client requests,” said Cecchini.

Using VICIVISON Measuring Machines enables them to be one step ahead in a competitive market. Cecchini said. “In terms of production and quality, we always try to have the best equipment available, and this machine can be used to carry out inspection on an entire line.”

The accuracy and simplicity of the VICIVISION Measuring Machine allows Trenton to better prioritize its time to more important tasks for its operational needs. Trenton uses an M2018 Techno with a Touchprobe to measure the many di erent parts they make in their manufacturing line.

“We can produce parts up to 1500 mm in length and inspect them on the Vici machine using the Touchprobe to measure keyway slots and planes. This machine measures parts 2000mm in length, and 180mm in width, giving Trenton the versatility they need in measuring the mechanical components they create,” Cecchini said.

Investing in a VICIVISION machine comes from the company’s decision to combine quantity and quality within production. That’s the focus that makes Trenton a cutting-edge company, capable of manufacturing many parts, from facing and centering to grinding.

Catching inaccuracies early can reduce the amount of waste, therefore saving a significant amount of time and money. Trenton’s Quality Control team said that it helps to know that they are starting production o on the right foot, especially with such a short setup time.”

They also explained that users can measure a part in 93 seconds, and the results indicate the validity of the part being measured. The tolerances for each measurement are defined by either a green or red line indicating the accuracy of the measurements for the product produced. Catching inaccuracies early can reduce the amount of waste, therefore saving a significant amount of time and money.

Trenton has had the Measuring Machine for a year, and over time they have created many new programs giving them the ability to increase the number of parts that are inspected. This intuitive machine allows for innovation in the process of the entire production, and with new technologies, it means that Trenton is better able to anticipate

its customer’s needs.

As Trenton continues to manufacture the many di erent parts in their production line, they know the decision to have this Measuring Machine involved in the process is a great investment that ensures e ciency and accuracy in making quality products. DW VICIVISION

www.vicivision.com

As Trenton continues to manufacture the many di erent parts in their production line, they know the decision to have this Measuring Machine involved in the process is a great investment that ensures e ciency and accuracy in making quality products.

The Automation Ecosystem from Formlabs enables new levels of 3D printing productivity with Form Auto for back-to-back throughput, Fleet Control for advanced fleet management, and High-Volume Resin System for high-capacity printing. The Automation Ecosystem reduces the amount of operator labor and minimizes idle printer time with 24/7 printing so users can e ciently produce enduse parts, prototypes, and customizable products at a lower cost-per-part.

The Automation Ecosystem enables users to expand from one Form 3+ or Form 3B+ 3D printer to a scalable fleet of 3D printers easily.

As users scale their 3D printing production from one to multiple printers, the Automation Ecosystem makes the transition easy without adding management

complexity. With the ability to manage multi-user, multimaterial printer fleets, the system enables continuous production so users can send multiple prints to run overnight and into the weekend. Together with Formlabs 3D printers, the Ecosystem provides a three-time increase in productivity while saving up to 80% on labor, lowering cost per part by 30%, and reducing packaging waste up to 90%.

The system includes:

• Form Auto: Form Auto enables automated 24/7 printing with automatic part removal so users can level up production and reduce labor. When parts are complete, Form Auto seamlessly removes finished parts from the Build Platform 2 using the patented Quick Release Technology, and starts the next print in the queue as soon as possible. The hardware extension works with Form 3 or Form 3+ 3D printers.

• Fleet Control: Fleet Control simplifies advanced 3D printer fleet management, optimizing workflows to maximize fleet productivity. It’s a suite of new features within Formlabs’ Dashboard and PreForm software that includes centralized queue management and automatic printer assignment to optimize production, performance, and printer e ciency with Form 3+, Form 3B+, Form 3L, and Form 3BL printer fleets.

• High Volume Resin System: The High Volume Resin System increases resin capacity to five liters, five times the standard cartridge size, enabling users to create more parts with fewer interruptions for cartridge replacements. This system streamlines workflows, with consistent resin dispensing with a Resin Pump while reducing downtime and user intervention to change cartridges, as well as packaging waste. This is compatible with the Form 3+, Form 3B+. Form 3L and Form 3BL. DW

Meltio is making it easier for customers to integrate its Meltio Engine CNC with its Engine Robot Integration systems. Meltio is a multinational wire-laser metal 3D printing manufacturer. Its engineering team developed 14 evaluation points, 9 focused on toolpath strategy, to ensure a comprehensive software ecosystem to meet a variety of customer needs.

The Meltio Engine Software Partners ecosystem includes key software players in the additive manufacturing market, and enables it to complement the Meltio Horizon to deliver end-to-end additive manufacturing software.

The key players that have joined Meltio Engine’s Software Partner ecosystem for hybrid and robotic platforms include SKM DCAM by SKM Informatik; AdaOne by Adaxis; AiSync by AiBuild; Esprit by Hexagon; Fusion 360 by Autodesk; Aplus+Mastercam by Camufacturing and Mastercam; Hypermill by OpenMind; SiemensNX by Siemens; Hy5CAM by 1ATechnologies; RobotStudio 3D Printing PowerPack by ABB; and SprutCAM X by SprutCam.

Meltio provides an open platform for hardware (any robot or CNC) and for software that allows the use of any software to manufacture metal parts and

meet the growing demand of industrial applications in the market with hybrid and robotic additive manufacturing processes.

Meltio has created a process for validating technically each solution, avoiding extra work between the final customer and every software provider, for example as defining post-processors or ensuring the specific software can get the most out of the Meltio Engine as the possibility to use two materials in the same part (Dual-Wire). Meltio’s engineers have studied the technical requirements for developing the slicing strategies for the majority of the parts that the industry requires. They have defined 9 levels of complexity, including example geometries that represent help customers as well as developers understand the diversity of parts.

This software ecosystem o ers to the market tools to address several parts and industries through advanced slicing features such as: fixed tool orientation, revolved surfaces, features on non-planar surfaces, simple surface coating, radial cladding, 360 features, variable layer deposition, controlled area repair, and non-controlled area repair. DW

Meltio Meltio3d.com

CoreTechnologie (CT) is cooperating with Meteor Inkjet Ltd. of the UK, a supplier of electronics, software, tools, and services for industrial 3D inkjet printing. The two partners will ensure integration of their software environments and develop innovative tools specifically designed for binder and material jet applications. The precision and multi-material capability of inkjet printing and new possibilities for automating additive manufacturing are the focus of the collaboration.

CoreTechnologie is the developer of 4D_Additive, a software suite for a seamless additive manufacturing process o ering functions for model repair, geometry analysis and optimization, support, lattice and surface texture generation, and nesting and slicing. Combined with Meteor’s world-leading printhead drive electronics and Met3D Digital Front End, it provides printer manufacturers with a straightforward path from design to production of inkjet printing systems for additive manufacturing.

The implementation of inkjet technology for the application of binders or materials requires a close integration of the hardware and software of industrial printing systems and innovative tools for additive manufacturing, as well as the reading capabilities for all common CAD formats and the provision of optimized 3D data in a special format for inkjet printers. DW

CoreTechnologie

www.coretechnologie.com/products/4d-additive

Jabil Inc. offers a forecast of five additive manufacturing trends that will continue to accelerate innovations this year.

According to a recent report from Grand View Research, the additive manufacturing market is projected to reach $76B by 2030, growing at a CAGR of 20.8% over the forecasted period. Aggressive market expansion is attributed in part to increased adoption of additive manufacturing in industrial applications and sustained momentum in incumbent industry segments, including automotive, healthcare, and aerospace and defense.

Here are five additive manufacturing predictions that Jesse Sumstad, senior product manager, Jabil Additive, sees as the additive manufacturing continues to mature.

1. Sustainable materials are having a moment. Increased demand for environmentally friendly materials is growing rapidly as companies seek more sustainable solutions to reduce raw materials, waste and carbon footprints. Moreover, regulatory pressures to recycle and repurpose plastic waste for 3D printing applications continues to gather momentum, especially in Europe where plastic waste pollution is being tackled on multiple levels. Equally important, the trend for bio-based and bio-compatible materials used in packaging and other traditional manufacturing applications is transitioning to the additive market. Examples include Jabil’s low-carbon PK 5000 and formaldehyde-free PA 0600.

2. Additive manufacturing processes need to be ecofriendly. While a lot of focus is on the development of sustainable, recyclable materials, expect to see this broaden to encompass demands for more eco-friendly processes and 3D printing platforms. Technical feasibility and research into more sustainable processes and machine platforms need to be addressed over the next 12-to-18 months as part of all-encompassing circular economy initiatives.

3. The industrialization of AM continues. Over the past year, additive manufacturing has seen an uptick in volume serial production of final parts. While prototyping and tooling still rank high on the list of AM applications, it’s clear that the production of end-use parts is growing, along with the availability of rigorous manufacturing processes and Quality Management Systems

(QMS) to ensure the highest levels of part reliability, resiliency and robustness. Future expansion is forecasted, especially for applications where Design for Additive Manufacturing (DfAM) is being used to design parts. Additionally, as the costs of additive manufacturing continue to come down, the ability to compete with injection molding increases, resulting in more viable uses for AM to manufacture end-use parts.

4. Applications are propelling pellet printers forward. Interest in pellet printers is growing alongside the availability of pellet-based materials for making large parts based on the favorable economics of this type of 3D printing. Continued expansion in this area is on the horizon, particularly for applications involving large-scale castings and patterns.

5. Custom materials nearing a heyday:

The push is on for custom materials as companies recognize opportunities to achieve extra ductility, flexibility, and agility with materials tailored for specific applications. In particular, growing interest in polyketone-based materials is being driven by the need for high degrees of impact strength while being resistant to most fuels and fuel additives. As a result, this type of engineered material is ideally suited for fuel-tank applications.

An additive manufacturing pioneer and manufacturing powerhouse, Jabil has supported market growth through its materials, processes and machines.

“As serial production becomes more viable and mainstream, we need to take a holistic view of the end-to-end part production ecosystem,” said Sumstad. “All the factors that impact success — from design for additive and the use of engineered materials to post-processing methods and cost of labor — must be part of the overall decision-making process.” DW

Jabil | www.jabil.com

For engineers and designers working on modern-day motion and other industrial applications, it’s vital to understand the advantages and disadvantages of stepper and brushless dc (BLDC) motors. Here we’ll look at a widely used hybrid stepper motor and a 3-phase BLDC motor and compare both devices. We’ll consider the working principles of these motors (physical size and power density) and make observations about the acceleration and noise aspects of each motor. Experiments performed under various load conditions reveal changes in power, e ciency, and temperature.

A comparative study of stepper vs. brushless dc motors reveals the pros and cons of both motor types.

The key dimensions of the EZmotion MMS742038-24-R1-1 BLDC motor and a general-purpose stepper motor used in the test setup are shown here.

Stepper motors

Most widely used stepper motors are hybrid stepper motors, which consist of permanent magnet rotors and electromagnet stators. Rotors have two cups with permanent magnets; one with north poles, and a second with south poles.

A simplified stepper motor has a rotor made of two cups of permanent magnets. Each cup has three teeth with a respective magnet pole. In this case, these cups are assembled such that they are out of phase by a half-pitch (60°). The stator consists of four poles with two phase windings.

Steppers are electronically commutated. According to step input pulses, the bipolar stepper driver uses a dual H-bridge circuit to energize the stator poles in a sequence that allows the rotor to rotate by a step angle. The step angle can be calculated with the following equation:

Step Angle (in °) = 360/(2 x (n_ROTORTEETH) (n_PHASE))

For each step pulse, the rotor rotates 30° — this stepper is known as a 12 full-step stepper motor. During full-step operation, the commutation sequence and rotor position follow a particular sequence. Most stepper motors on the market have 50 or 100 pole pairs, with 200 or 400 full steps for one full rotor revolution. This makes the step angle as small as 1.8° or 0.9°.

With an advanced stepper motor driver, this small step angle can be further divided into even smaller angles by implementing microstepping operation. The step angle can be reduced by a half-step, quarter-step, and

The graphics show the simplified working principles of hybrid bipolar stepper motors.

Here, the working principles of a BLDC motor and a simplified single pole pair 3-phase BLDC motor (denoted as (a) and (b) in the figure respectively) are shown.

up to a 1/256 step. Stepper motors o er superior positional accuracy because they can step by such small angles.

Brushless dc motors have a permanent magnet rotor and electromagnet stator and require electronic commutation. To commutate brushless dc motors, the instantaneous position of the rotor is required. To meet this requirement, Hall-e ect sensors are used to realize the rotor’s angular position. This information is fed to a microcontroller (MCU) that switches the phase winding current using the 3-phase inverter circuit. Essentially, the dc input voltage is converted to 3-phase ac voltage to sequentially energize the stator poles using an inverter circuit.

The rotor magnetic field always chases the stator magnetic field, which results in the motor spinning. Because the simplified motor is a single pole pair BLDC, each commutation step is 60 electrical and mechanical degrees. BLDC trapezoidal commutation and the rotor position can be obtained. However, typical trapezoidal commutation makes the motor susceptible to torque ripple. As a result, an advanced commutation technique called field-oriented control (FOC) is used on the motor for testing. FOC provides minimal torque ripple and smooth motor operation.

To set up the stepper motor test, a NEMA 23 bipolar stepper motor is used along with a magnetic particle brake for load simulation. The motor test requires five main components described below:

• An encoder (mounted on the particle brake’s other end) monitors the shaft’s rotational speed.

• A bipolar stepper motor driver — featuring parallel inputs, internal current sensing, and regulation — controls the stepper motor.

• A 24V dc bench supply placed in series with a current meter measures the dc current draw of the stepper motor under di erent load conditions. In addition, the 24V dc bench supply powers the stepper motor driver.

• The motor driver’s MotionLAB, which is compatible with the serial peripheral interface (SPI), configures the stepper motor driver’s parameters, such as the step mode, rated current, and additional motor settings.

• A function generator sends square pulses to the driver, which drives the motor forward.

Similar to the stepper motor test, the brushless dc motor test set-up includes a magnetic particle brake for load simulation, as well as a NEMA 17 BLDC motor with an integrated controller.

To power the controller, a 24V dc bench supply is used in series with a current meter to measure the dc current draw of the brushless dc motor under di erent load conditions. Then the MotionLAB GUI can drive the BLDC in speed control mode for this test.

Steppers typically operate under constant current, otherwise known as constant torque. This forces steppers to always draw the maximum current, regardless of the load on the motor shaft. As a result, steppers can provide maximum torque across the low-speed range. However, this also leads to large amounts of wasted energy in the windings in the form of heat.

In this experiment, the stepper motor was tested in three microstepping resolutions: half-step, fourth-step, and eighth-step. The dc

The dc current draw at various motor speeds under di erent load conditions are

current draw was recorded at various motors speeds under three di erent load conditions (no load, 8.2 N-cm, and 11.5 N-cm). The experimental results demonstrate the stepper motor’s less e cient measured dc current draw compared to a BLDC motor.

The no-load current draw was also measured for the brushless dc motor, half-step stepper motor, fourth-step stepper motor, and eighth-step stepper motor. The stepper motor draws a significantly higher zero-speed current than the BLDC, even when there is no mechanical operation. Furthermore, the stepper motor current draw remains high across the low-speed range. As the motor speed increases to the high-speed range, the stepper motor’s current draw begins to decrease due to the inductance of the motor windings and back EMF.

Next, the current draw was measured for the BLDC motor, half-step stepper motor, fourth-step stepper motor, and eighth-step stepper motor when there was some load added on the shaft. The stepper motors stall at high speeds because they have less current in the windings. Although microstepping increases the motor’s positional resolution, it also decreases the output torque. The eight-step and fourth-step stepper motors stalled at the midrange speed as well. Meanwhile, the BLDC motor only draws what it needs depending on the shaft’s load.

Under no-load conditions, the BLDC draws a small current to rotate the rotor. At the same time, the current draw increases if load is added to the shaft, allowing the BLDC motor to continue spinning at a higher speed than the stepper motor. Therefore, BLDC motors

are more power-e cient compared to stepper motors due to their ability to draw current based on the load.

Power density is a measure of motor output power per unit volume. Brushless dc motors typically have higher power density compared to stepper motors.

Using these dimensions, the volume can be estimated as 73 cm3 for the BLDC motor and 131 cm3 for the stepper motor. A motor’s output power is equal to the output speed multiplied by the output torque. The BLDC motor continues to spin at a higher speed compared to the stepper motor under the same load conditions, which means that the BLDC motor provides a higher power density, because it has a higher power output with a smaller volume.

This area has long been one of the most read and sought after by our engineering audience! From screws to bolts and adhesives to springs, these critical but often overlooked components are the key to every successful design.

FastenerEngineering.com will serve readers in the mechanical design engineering space, providing news, product developments, application stories, technical how-to articles, and analysis of engineering trends. This site will focus on key issues facing the engineering markets around fastener technology, along with technical background on selected components.

ADDITIONAL RESOURCES:

• Special print section in select issues of Design World

• Fastener Engineering monthly newsletter

Power density plays an important role in applications with limited available space and a high power requirement, such as drones and quadcopters.

As mentioned previously, constant current operation for the stepper motor leads to major energy losses in the windings, mainly in the form of heat. During the experiment, the motors’ body temperature was measured in an ambient temperature of 22°C.

The stepper motor’s temperature rises steadily regardless of the load on the shaft. In comparison, the brushless dc motor’s ability to not draw excessive current means the body

temperature only increases minimally. Unlike stepper motors, BLDCs convert a high percentage of input power into mechanical power instead of heat.

The high pole count of steppers is directly responsible for their superior positional accuracy over BLDCs. However, the high pole count also results in limited acceleration and more audible noise during operation. Accelerating a stepper motor can be difficult because it requires a gradual ramping of motor speed to sustain the shaft’s angular positional accuracy. If a stepper accelerates quickly, then it faces the risk of missing steps, which

can cause issues in many applications. In addition, if there is low input current combined with high acceleration demand, then the stepper may stall.

In terms of noise, brushless dc and stepper motors can detect a particular torque, otherwise known as cogging torque, which causes vibrations and ringing at every step of the stepper motor rotation. Because the BLDC current draw is proportional to the load on the shaft, BLDCs can draw the additional current required to accelerate the load within the motor’s rated speed range. BLDCs are much quieter during normal operation than steppers. Therefore, BLDC motors are reliable and efficient solutions that offer high speed, high acceleration, and less audible noise.

While the positional accuracy of BLDC motors is proportional to the angle sensor accuracy, integrated BLDC motors with a high-resolution angle sensor can offer exceptional positional accuracy. With microstepping, stepper motors offer superior positional accuracy over brushless dc motors. This comes with the disadvantage of offering less torque beginning from mid-range speeds, which lead to missing steps or stalling. Steppers lack the ability to quickly accelerate, and they produce more noise than BLDCs. Overall, stepper motors are a less expensive solution, but they are limited to lowspeed applications. BLDC motors are dependable, quieter solutions that offer higher efficiency and accuracy across a wide speed range. DW

(two shows, one price)

The International Fluid Power Exposition (IFPE) is the place where engineers meet to:

Spark new ideas with in-depth technical conversations with other engineers.

Discover solutions current suppliers can offer to your unique challenges.

Find new partners among suppliers pushing the envelope on what fluid power can do.

Including Bosch Rexroth , Danfoss Power Solutions , Parker Hannifin , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more!

Join your peers from these OEMs:

∙ Caterpillar Inc

∙ Volvo Construction Equipment

∙ Liebherr

∙ CASE Construction Equipment

∙ Komatsu

∙ John Deere Construction

∙ Doosan Bobcat

∙

KOBELCO Construction Machinery USA

∙ LBX Company

“ There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

KEN ROSENBECKER SALES MANAGER NORTH AMERICA | WIPRO INFRASTRUCTURE ENGINEERING

See why IFPE is the can’t-miss fluid power event of 2023! Learn more at IFPE.com

INTERNATIONAL FLUID POWER EXPO

MARCH 14-18, 2023

LAS VEGAS, NV, USA

editor

editor

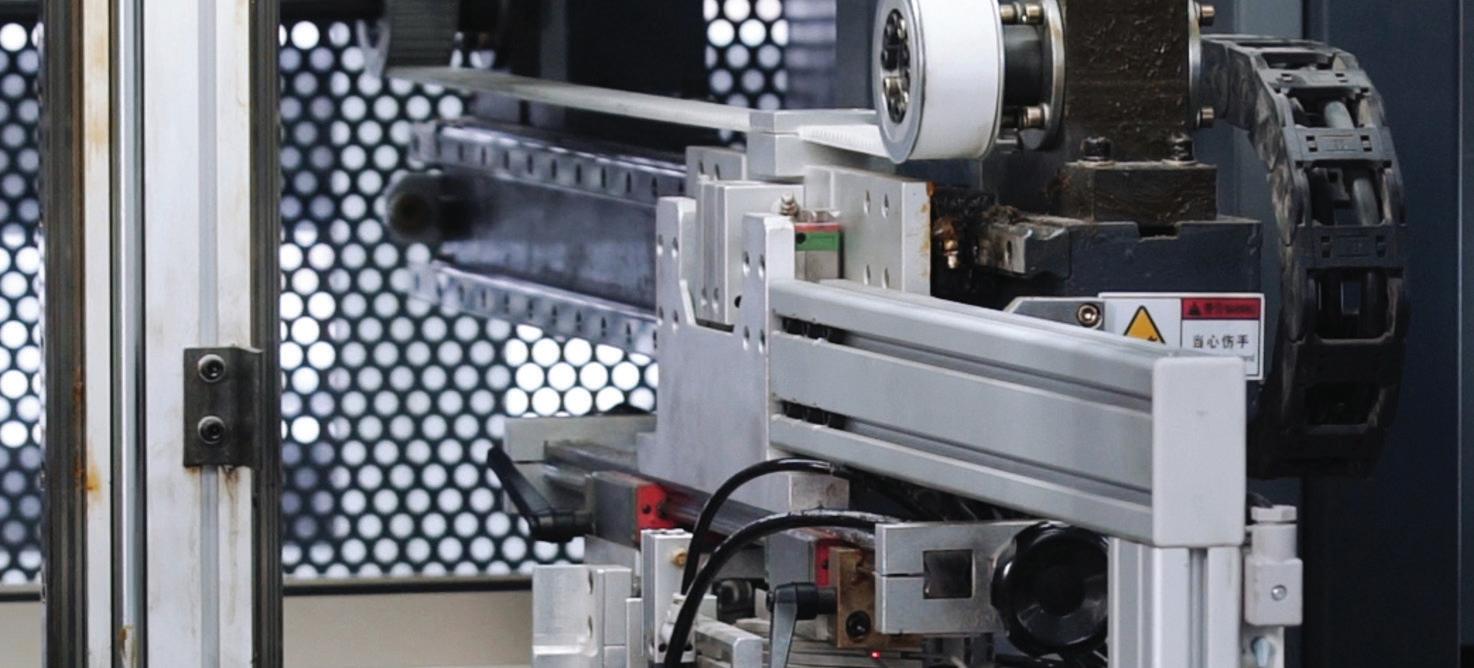

Industrial belt drives in motion designs consist of rubber, engineered plastic, metal, or (most common) multimaterial belts that wrap around drive pulleys — grooved or otherwise profiled wheels mounted on a shaft — in turn driven by electric motors. Powered by various motor types, belt drives run axes transmitting fractional horsepower to 7,000 hp or more. Most belt drives in motion designs also wrap the belt around one or more idler pulleys that keep the belt taut and on track. While industrial belts are generally non-serviceable and can exhibit wear and vulnerability to oil as well as debris contamination, their benefits abound. The main reasons that engineers pick belt drives over other options is that modern varieties require little if no maintenance; they’re less expensive than chain drives; and they’re quiet and e cient, even up to 95% or more. In addition, the tensile members of today’s belts — cords embedded into the belt rubber that carry most of the belt load — are stronger than ever.

Belt drives have continued to evolve with new applications.

Belt drives are indispensable in cartoning (cardboard-box folding) applications.

| Dreamstime

| Dreamstime

Made of steel, polyester, aramid, fiberglass, or carbon fiber, these tensile cords render today’s belt drives thoroughly modern power-transmission devices.

Note: Terminology for belt drives is more consistent than that for other motion components. That said, in some contexts the term sheave is used instead of pulley. The terms sheave and pulley are interchangeable, with few regions and industries di erentiating sheave to mean any drive pulley — distinct from idler pulleys that have flat (or simply profiled) outer diameters. Otherwise, sheave can imply a rugged steel or cast-iron drive wheel that’s less precisely cast or machined than the pulleys found in motion designs — which are our primary focus in this article.

Flat belts are the original design for automated machinery — first applied in such designs during the first Industrial Revolution and before. In fact, flat belts were and remain especially important in pump and sawmill operations — and once reigned supreme in driving many axes o common steam-powered line drives through factories. Versions made of leather quickly gave way to rubber and neoprene — hastened by the innovations of the burgeoning automotive industry and new forms of independent pieces of machinery run o electric motors. Today, highly engineered flat belts still find myriad uses in conveying and materialhandling applications.

However, the faster axis speeds associated with many motor-powered

Recent years have seen convergence of specialty belt drive systems in mass-produced consumer and light industrial tools with standard belt drives integrated into various machine designs.Machine designs often employ gear, chain, and belt drives for power transmission. The latter come in V belt and synchronous-belt variations (as the ones shown here) to serve different applications. | Gennady Danilkin

designs necessitated belts with new geometry — so next came V belts having trapezoidal cross sections. Their easier tracking on pulleys and higher friction (which we’ll explain more on a moment) also allow high force transmission even at tension values lower than typical.

Reinforced cords embedded in belt backing — the tension-carrying zone — was another innovation still core to modern belt variations.

Combining flat and V-belt design elements are ribbed or poly-groove V belts — those with a cord-reinforced tension-bearing face and multiple trapezoidal profiles running the inner belt circumference. Drives based on ribbed V belts are exceptionally compact and necessitate lower tensions than flat belts.

Other belt-related innovations came to include the introduction of toothed belts for synchronous chain-like operation; heat-resistant belt insulation layers; elasticized and other highly engineered working belt surfaces; and pre-stretched tensile cords of various materials.

Recent years have seen convergence of specialty belt drive systems in mass-produced consumer

and light industrial tools with the standard belt drives integrated into various machine designs. That’s because options have proliferated for belts with flat and round profiles as well as those with various V-shaped profiles and toothed belts for synchronous operation.

The Association for Rubber Products Manufacturers (ARPM) originating from the Rubber

Manufacturers Association (RMA) and the National Industrial Belting Association (NIBA) along with component suppliers dictate the details of how the geometries and performance of these industrial belt drives are standardized and quantified.

Many manufacturers describe belts and pulleys with fi ve main geometries. Pitch diameter is the drive pulley’s diameter. Center distance is the distance between the two pulleys’ centers. Minimum wrap angle is a measure of how much the belt wraps around the smallest pulley. Belt length is how long the belt would be if cut and laid flat. Finally, in the case of toothed belts (also called synchronous belts) the pitch is the number of teeth per some length — so a 3-mm pitch means that the belt has one tooth every 3 mm, for example.

Power ratings based on belt and pulley size (along with motor output) are adjusted for the belt-drive length and wrap diameters. Traditionally, charts of belt geometries and counts, horsepower ratings, and speed and force capabilities assist design engineers in the specification process. Today, sizing and selection software tools abound to match required values to a machine axis’ geometry and torque (output force) and speed requirements. These also provide service-factor adjustments informed by the belt or other component supplier’s own historical experience with given industry and application type. DW

Linear Motion Tips | linearmotiontips.com

Silicon Carbide (SiC) has made its mark in bringing faster, a smaller, and more reliable components than its fellow semiconductors to market. While SiC components have been around for a couple of decades, there is still a lot to learn and a lot to consider when choosing the most suitable WBG semiconductor for your device.

LET US HELP with tutorials, from looking at how WBG semis stack up in power conversion efficiency to an overview of SiC FETs and MOSFETs.

Check out our EE Classroom to learn more: www.eeworldonline.com/silicon-carbide-classroom

As more industrial and commercial applications are requiring greater functionality, there is a need for low-profile input devices that enable users to achieve fine control, even in the harshest field environments.

Antonin Deschamps • APEMMany heavy-duty industrial and commercial applications, despite the large scope and scale of driven equipment, still need delicate operator-initiated control for various aspects of their operation. For instance, a massive gantry crane may require precise positioning of the pickup apparatus, or a construction equipment operator may need to set the position of a blade or other attachment. Incorporating these types of fine control, along with other types of operator input, can be challenging in an industrial setting (Figure 1).

Furthermore, as digital automation methods have become the norm, along with an increasing availability of electronic sensors, machines are gaining much more functionality than traditional and basic systems. Whether the application is a fixed installation, a portable piece of equipment, or a vehicle, these additional technologies are prompting a greater need for industrial-rated operator control devices able to provide a responsive and accurate interface to digital controls while surviving the rigors of the environment.

Putting precise control into the hands and fingers of operators takes many forms. For some modern systems, touchscreen displays are incorporated into the design. Touchscreens work fine for personal electronics, but their relative fragility and lack of tactile feedback make them less than ideal for heavy-duty equipment applications.

Proportional joysticks address these and other issues. True proportional joysticks — which are different than simple on/off control at each compass point — are a classic form of operator input for relatively delicate actions. These types of joysticks are commonly seen in certain aircraft controls or video games, providing an excellent way for operators to command two (X-Y) or more axes of motion in a smooth and positional manner.

However, using the whole hand and arm may not provide the finest control

because an operator’s thumb and index finger are much more agile. Using a full-size joystick is less practical when there are many pairs of axes to be controlled. Another consideration is that the relatively large size of a traditional proportional joystick makes it more susceptible to damage or unintended operation.

In many cases, the best solution to address these issues and provide refined control in a robust form factor is to use a low-profile joystick, sometimes

called a thumbstick, which can be used by the thumb or fingers.

Many of the most challenging industrial, commercial, and marine applications require extensive operator interface. Sometimes an operator input device can be mounted in a relatively protected fixed location, like a control panel. But more commonly, operators need to be close to the work. This means that wired or wireless consoles, vehicle armrests, pendants, and belly boxes must be populated with several operator interface devices. Each of these locations is space-constrained and subject to considerable abuse. Belly boxes can be dropped, where an extended joystick can absorb a significant impact. Controls on board a pitching ship or vehicle may serve as an ill-advised handhold. These actions can damage flimsy devices and create undesirable and potentially dangerous equipment operation.

For these reasons, thumbsticks should be compact and extend no more than about 2-in. above a panel face. This minimized height makes them less vulnerable to impact, and it also means that any guarding provisions can be low enough to avoid interfering with operator use. A low-profile thumbstick also makes it

suitable for multiple devices to be installed on dense control arrays while providing easy operator access.

A low profile is important but may not be enough to protect a generic thumbstick when exposed to damaging force. Therefore, thumbsticks made for industry should have a stainless-steel shaft, along with similarly tough metal gimble and base mechanicals and limiters. Because bare metal is not an ideal contact surface for operators, the stick and cap should be covered by a material such as nylon, which provides a durable yet easily gripped surface (Figure 2).

Thumbstick applications are often exposed to falling or directed water, so these devices must be rated at least IP66. This is best accomplished with a convoluted gaiter to protect the moving location where the stick enters the device, in combination with a robust panel mounting design that permits dropin or rear-mount installation for the best design flexibility. Users should also look for devices rated for an ultra-wide temperature range to guarantee performance under harsh conditions.

Older joystick designs may have used relatively fragile and short-lived potentiometers, but today’s designers should instead insist on proven Hall e ect sensor technology. Non-contact Hall e ect sensors, operating at standard 3.3 or 5VDC and implemented in conjunction with robust mechanicals, result in a device that can endure an expected lifetime of 10 million cycles.

Older joystick designs may have used relatively fragile and short-lived potentiometers, but today’s designers should instead insist on proven Hall effect sensor technology.

For compatibility with the widest range of applications with X or X-Y axes, the Hall e ect sensors should be capable of operating as single- or dual-axis, with dual and dual-inverse outputs available in analog or PWM formats. The availability of center-detect functionality, and center-tap signaling (Z-axis pushbutton), provides even more options for designers to fine-tune the device selection to meet their needs.

In fact, designers should look for a device meeting not only the criteria described above, but also providing su cient configuration flexibility in terms of:

• Signaling options

• Gain levels

• Movement limiters

• Handle shapes

• Spring force levels

• Colors

Industrial-grade thumbsticks should be able to survive a 1m free fall and be rated for vibration, EMC, and ESD resistance in accordance with applicable IEC standards. Designers should ensure the products they select come with a comprehensive validation plan, ensuring adherence to all standards and performance requirements.

Providing practical operator controls for space-constrained belly boxes is a prime use case for thumbsticks. Some belly boxes are wired but are still relatively heavy and require a neck strap, while wireless versions can be even more weighty due to batteries. One drop as the box is picked up or removed can be catastrophic for the input devices unless they are built to withstand this type of rough treatment. Add to these considerations the fact that belly boxes are often used in highEMI environments due to welding, and the need for rugged and properly rated operator input devices becomes clear (Figure 3).

The control console of a ship is another prime application for functions, such as thrusters, requiring precise operator control. Obviously, any shipboard device or instrument can be subject to water spray, but some users may think of a marine control panel as relatively protected from a mechanical standpoint. However, aboard a constantly moving ship, it can be quite common for users to grab anything handy to keep their balance. Thumbsticks are less susceptible to this problem than a larger joystick, and well-built thumbsticks will easily survive such abuse.

In addition to the above industrial and marine applications, there are also many commercial applications for thumbsticks. As electric vehicles and other transport equipment, such as wheelchairs, become more advanced, they need user input devices sized for convenient use but tough enough to handle mistreatment.