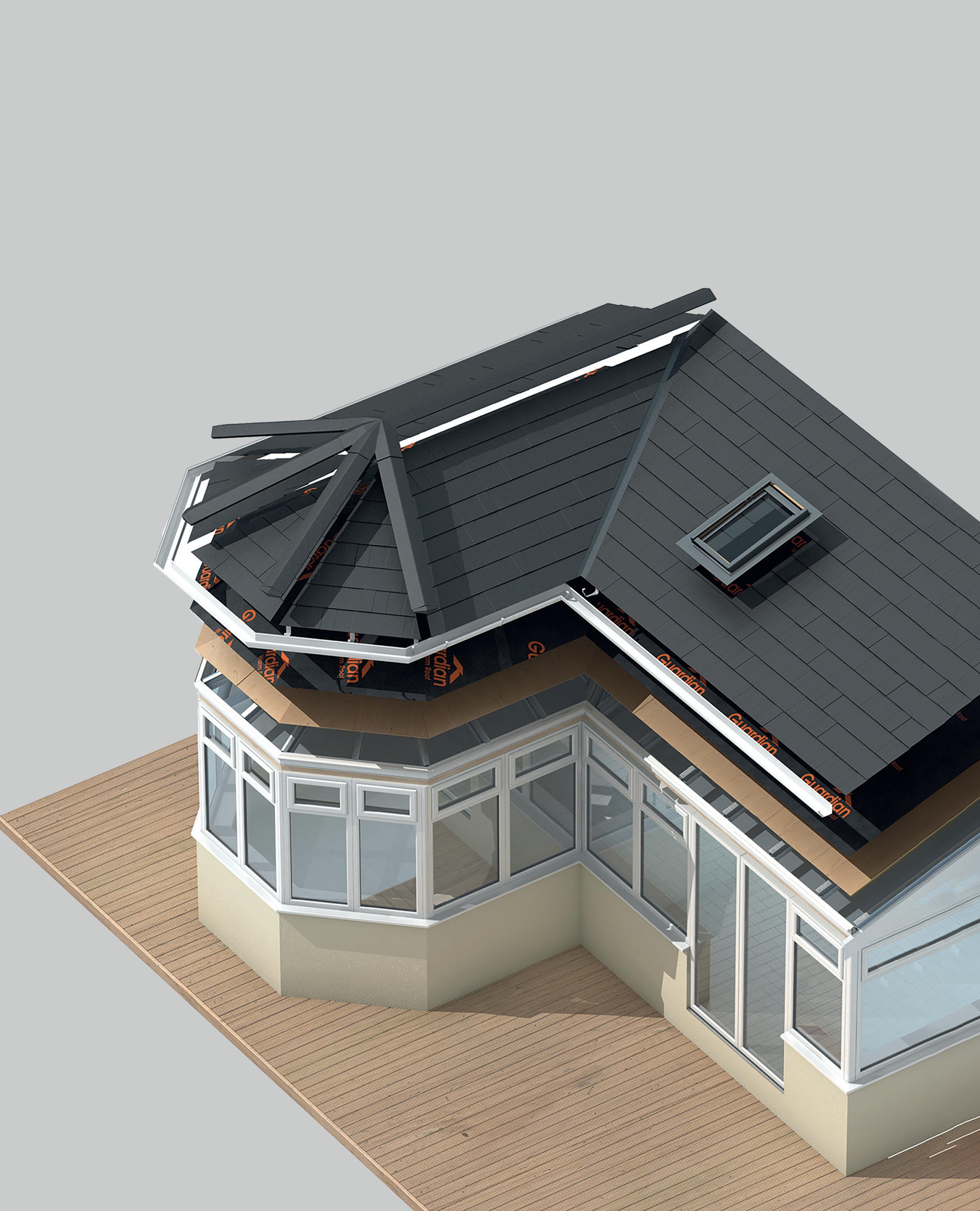

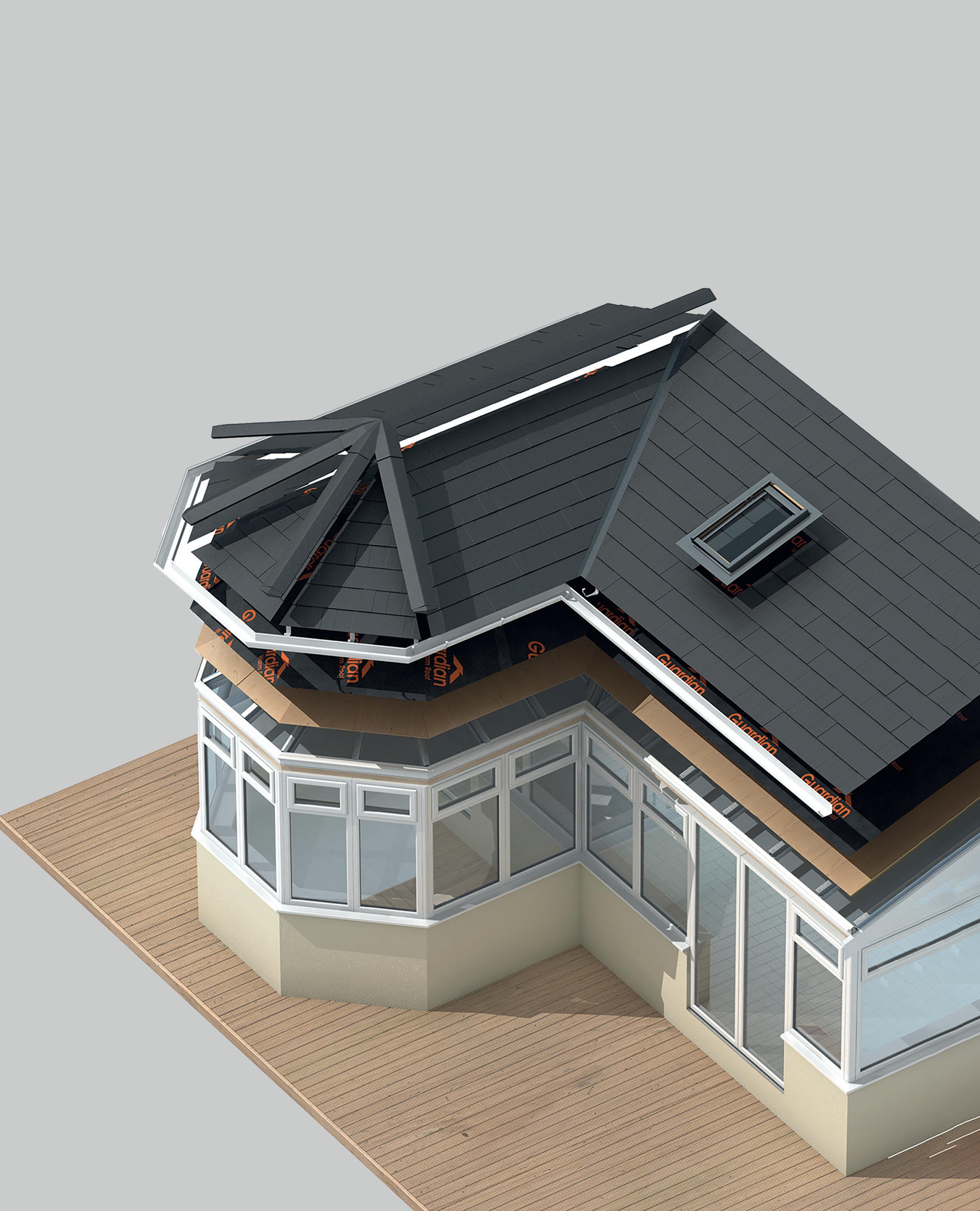

An initiative from Pearl Window Systems

Making life easy for the home builder

An initiative from Pearl Window Systems

Making life easy for the home builder

How effective is your marketing?

Are you growing market share, losing to competitors or treading water and drifting, asks Mike Rigby, CEO of MRA Research?

In the last 10 years, researchers working on marketing effectiveness have changed the standing and practice of marketing. Stung by criticism that marketing was more art than science, and where was the proof that marketing worked and how it worked, researchers set out to establish beyond doubt what works and what doesn’t. The result? Several important things are no longer matters of opinion or debate.

Two researchers in particular, Les Binet and Peter Field, have been conducting large scale, long running analyses on the database of many thousands of marketing case studies gathered over decades by the Institute of Practitioners of Advertising.

They’ve discovered a lot but, as we hover near recession, two things they’ve proved conclusively are timely.

The first is about marketing in recession. Is it smarter

to cut or stop spending on marketing until the economy recovers? Or should you maintain or increase your spend? It turns out that companies that ‘go dark’ and cut spending, get a short term lift from the savings they make, but pay dearly for it later. They do much worse in the medium to long term. Few recover the loss of share and momentum.

Why? Firms that do less make it easier for others who do the same or more. Their ‘Share of Voice’ becomes greater, so they

become top of mind, and being top of mind is a key driver in customer acquisition, off and online. Firms that stay in the game do better in recession and enter recovery with momentum and raised awareness. Firms who go dark lose momentum and awareness. Restarting takes time and reconnecting is hard. Cutting marketing therefore has profound consequences. Lost momentum is often lost for ever.

Continued on page 4...

NFA New Product of the Year, the revolutionary double-rebated flush sash Resurgence window from Liniar offers all the charm of a traditional timber window with the benefits of exceptional modern energy efficiency.

Resurgence is designed with a range of fabrication options, from mechanically jointed to Timberweld® and is simple to install, with no glass bonding.

Stocked in range of modern colours, Liniar’s most recent addition to its window suite delivers patented perfection.

A UK first, with double co-extruded bubble gaskets and an external seal discreetly mounted out of sight, Resurgence looks as beautifully as it performs.

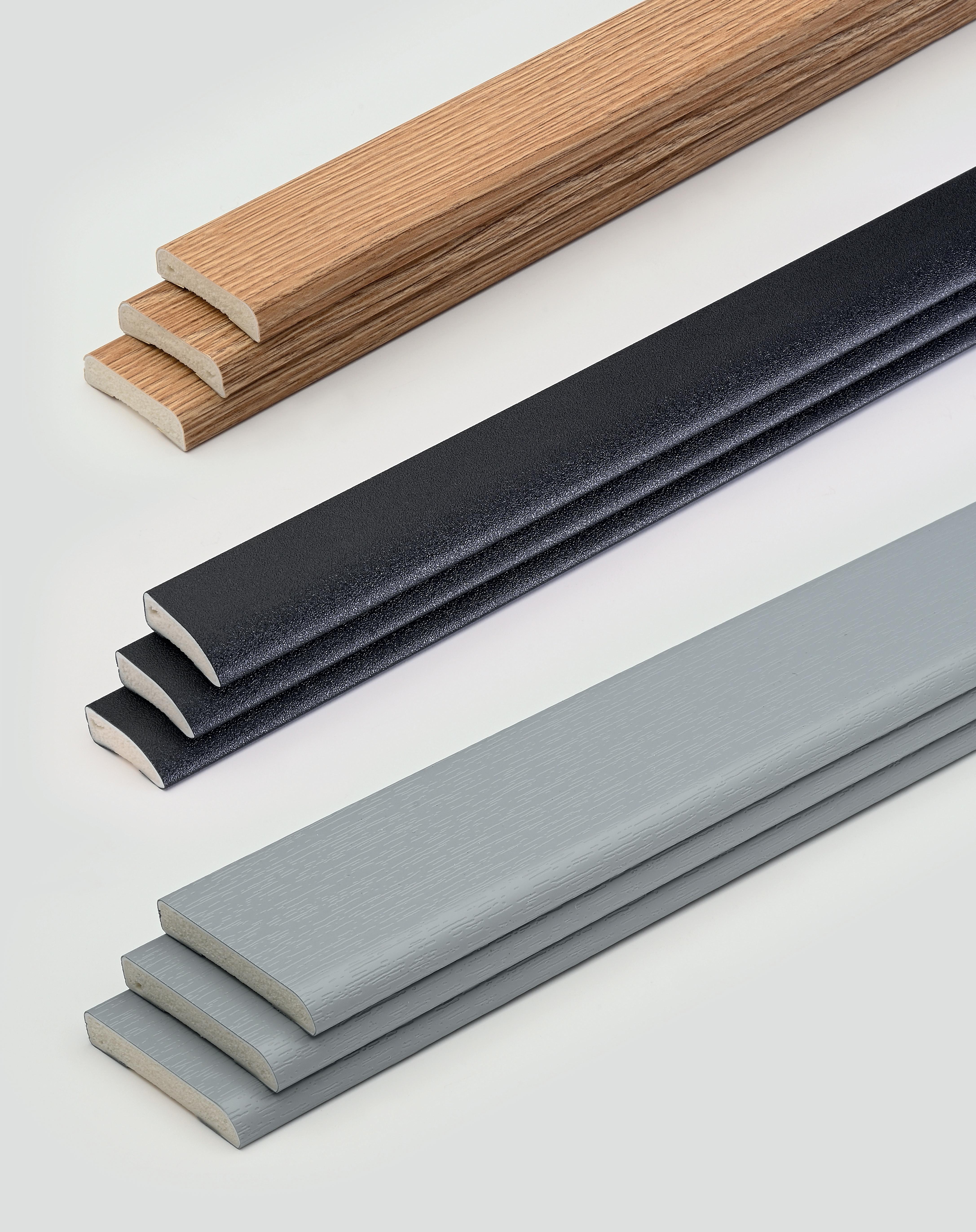

Customers want more choice - and with Liniar’s outdoor range you can offer more than ever before!

Liniar’s low maintenance PVCu decking and fencing ranges are designed, manufactured and stocked right here in the UK. Available in a range of styles, a variety of colours and a wide variety of accessories including foiled balustrades to match Liniar windows and doors, outdoor products are the idea opportunity to provide a fully matching finish with a single point of contact for guarantees.

As we progress through post-lockdown life, consumer enquiries for PVCu decking and fencing have skyrocketed – don’t miss out on the chance to provide homeowners with just what they want.

Find out more:

https://www.liniar.co.uk/outdoor-range/.

‘Ne'er cast a clout 'til May be out’ and all that stuff, but here I am writing this in February and it is really feeling as if Spring is just around the corner. Everything is budding in the garden and bulbs are pushing their way into the fresh air – OK, there’s every chance that we’ll get hit with another variation on the ‘Beast from the East’ but let’s enjoy what we have and look forward to those days of walking around in shirt sleeves again!

These positive vibes may not be echoed by the Bank of England, nor the IMF, but at least it was encouraging that only around 20% of civil servants acknowledged the day for strikes by anyone who has a nicely protected final salary pension. Mind you if they have been on their normal WFH… walking the dog and picking up the kids from school (if it was open) perhaps they never heard that they were meant to be on strike, not that anyone would have noticed the difference anyway.

I’ve been on a bit of a mission this month, helping a well-known lady at a system house try and identify how many times poly vinyl chloride can be recycled. If anyone has a definitive answer to this conundrum I would be pleased to hear it. There are lots of claims even to as many as 10 times but it seems very difficult to find out the source from whence this pearl of wisdom came! I’ve been reading a fair selection of scientific papers and emailing off around the world, from Poland to the US of A, but I have yet to get confirmation of what may yet prove to be a myth. Watch this space and I shall share my findings!

With confirmation from our friends at the FIT Show that the Exhibitor Enhancement Day is being held at the NEC on 24th February, by the time you read this you will have had the opportunity to appear in FIT’s marketing campaign, both in person, and with your product. You will also have had a good refresher on Sales Training and know how best to get a return on investment out of your attendance at FIT. Before we know it, we’ll be traipsing off down to Birmingham for the exhibition proper and, I have to say, I’m thoroughly looking forward to it!

The trade really is livening up with a rash of product launches and visits, all booked into the diary. Interestingly, new build has caught the imagination of the trade and we attended a presentation of Pearl Window Systems’ New Build Installer Network, an initiative that makes life so much easier for the builder with a complete supply chain solution for the house builder through a network of approved installers with support from Pearl’s key partners adding up to a national installation solution that meets all the requirements for quality, compliance (through CORGI Fenestration) and sustainability. There’s a full article on Pearl’s initiative in this issue of Glass News and, as they say, I commend it to the house!

Liniar, too, has new build in mind particularly in view of the expected Future Homes Standard that comes into being in 2025. The launch of Zero|90 for new build and Zero|90R for replacement of 70mm systems was to Liniar customers as well as house builders, specifiers and architects, and the system with its Passivhaus accreditation was very impressive. Again, you can read all about Zero|90 in this issue of our paper.

It was with sadness that I read the release from the GGF that Anda Gregory was leaving the organisation. While I’m sure everyone wishes her well in whatever role she chooses next I can’t help feeling that her leadership, professionalism and enthusiasm will be greatly missed. As MD for the commercial arm of the GGF she was excellent and broke down many of the barriers that seemed to have formed between the organisation and other factions within the industry and, when she jointly led the whole organisation alongside John Agnew, many of us were delighted she was heading it up and that the GGF would benefit from her drive and clear thinking. All the very best for the future, Anda. I wonder how our industry is doing as far as filling the many vacancies that are available? Are we managing to attract the workforce that’s required? One thing that is evidently working is apprenticeships –the so called ‘earn and learn as you work’. Seeing a release from Glazerite about their apprenticeship scheme made me hopeful for the future. Their apprentices are aged from 16 through to 32 and cover a whole range of disciplines within the company from HR and Marketing to Purchasing and Technical. They are supported in gaining qualifications and, importantly, valued by the company. Good for Group Managing Director, Rob Brearley and his team.

Email Chris at: chris@glassnews.co.uk

Continued from page 1...

Second, how you market matters. Is it smarter to focus on short-term sales activation to generate leads and traffic, with offers to motivate people to buy now? Or better to focus on the long, building your brand and awareness? What’s the optimum balance between short and long?

The optimum varies by market and by B2C and B2B, but as a rule of thumb it pays to allocate around 60% of budget to brand building and awareness, and 40% to sales activation. But it turns out, long is better at both anyway: brand building builds brand and awareness and is more effective at sales activation.

The window and door market is a mass of individual markets, but it’s surprising how static brand line-ups are. There are new faces but, like trench warfare, in many markets 40 years can pass and the No 1, 2 and 3 brands are still the top three. Yet markets change, sometimes radically as we’ve seen in the last three years. Yesterday’s facts and insights can date and quickly become obsolete.

If, consciously or unconsciously, you are employing the same assumptions and insights as everyone else, using the same playbook as your competitors, and playing the market leader’s game, how will your marketing be significantly different or more effective? And without stepping outside your own bubble to ask the right questions, of the right people, in the right way, how will that change?

Bubble? We can thank the debates about social media for revealing the insidious and largely invisible effect of social bubbles. Whether we’re fully aware of them or not, we tend to cluster in bubbles of like minded people who share and reinforce our beliefs and values, so it becomes hard to see things as they really are.

But that’s what sales teams are for? So, people say, why do we need market research to tell us what the sales team already knows? They talk to customers and the market day in day out. They know our products, markets, customers and competitors better than anyone. True, the very best probably do. But our research consistently shows the effects of ‘the bubble.’ Confident your management team can beat the bubble? Put it to the test! Even the closest customers aren’t an open book, and your team see the world through a group lens. If they’re any good, they must do. The positive of that is the strength of the team, the negative, the blinker of groupthink. We see what we expect to see. Just as fish are unaware of the water they swim in, few people sense the bubbles they live and work in.

This could be your most valuable takeaway: Good research is the foundation of effective marketing. Research can provide fresh insights and facts, facts you know that your competitors don’t. Facts and insights to transform your marketing, competitive advantage and market share.

Are you doing enough research, of the right kind? Or just waiting for the tide to turn and carry you with it?

If you want help researching the insights and facts to build your brand and make your marketing more effective, talk to Yvette Kirk at yvette@mra-research.co.uk.

“Is it smarter to cut or stop spending on marketing until the economy recovers? Or should you maintain or increase your spend? It turns out that companies that ‘go dark’ and cut spending, get a short term lift from the savings they make, but pay dearly for it later. They do much worse in the medium to long term. Few recover the loss of share and momentum.”

Rockdoor - The Original Composite Door, have released an entirely new, industry first door texture as an alternative to traditional woodgrain.

After making an appearance at last year’s FIT show, the manufacturer have now released their entirely new composite door texture.

The Dune gets its name from the intricate waves pattern running horizontally across the door from edge to edge, reminiscent of sand dunes running across the door.

Completed by two individual glazing options – the Dune Retreat and the Dune Vision, are Rockdoor’s solution to a truly contemporary composite door.

Joint MD of Rockdoor, Simon Bird explains why Rockdoor decided to create a new door texture entirely:

“When we first started looking for the answer to a truly contemporary Rockdoor, we realised we had to create something that didn’t follow traditional composite door traits.

“The majority of all composite door textures, including all current Rockdoors’ feature a woodgrain design, largely because of the old timber doors of the late twentieth century that homeowners around the country have come to love. But this ultimately meant that even really modern door styles could never be truly contemporary.

“Combine this with the shift in some homeowners now leaning towards more modern styles, which is apparent, so the Dune texture has become our very own solution to creating a truly contemporary composite door.”

The Dune Vision and Dune Retreat are available for ordering now through their ordering portal or can be viewed on their specialist 3D door designer on Rockdoor.com.

The trade specialists celebrate three decades of serving their customers.

Back in 1993, a close-knit team of friends, led by Simon Bird and Charles Greensmith, set up a small business, with big ambitions for the future.

General All-purpose Plastics, known as GAP, opened their very first depot in Accrington, Lancashire, selling PVC-U trims, silicones and fixings to local window and door installers. This quickly became the platform for growth which would help the business flourish in the years to come.

The double-glazing boom was already in full swing in 1993 when GAP was started, with the PVC-U roofline replacement market also growing thick and fast. This led to GAP expanding quickly over the years, to better serve its customers from depots across the country. Over 85 depots are now operated by the business from Inverness to Southampton.

In addition to a large depot network, the team at GAP have also created some muchloved industry brands such as Rockdoor and HomeLine. GAP also manufactured a range of door panels under the Cosmopolitan brand, that were extremely popular in their time.

Today, even more products are manufactured inhouse including their own range of aluminium bi folds, GRP

composite doors and PVC-U windows.

Reflecting on the last thirty years, Joint MD’s Simon Bird and Charles Greensmith, have attributed their success to their fantastic team created over the years and their customers:

“When we started GAP we loved the industry, our customers and our fantastic team. Thirty years on, those same things we loved, still inspire us when heading to work every morning.

“Of course, a lot has changed in thirty years, as any business operating during these times can testify. We’ve experienced the fantastic highs of natural expansion, acquisitions and new product developments, through to the more difficult periods of recessions, credit crunches and pandemics more recently. So, to be able to mark our thirty years, makes us very proud for what our fantastic team have achieved. We’ve learnt a lot along our journey, through good and bad, which has afforded us the insight to make better decisions along the way.

“The company business model might have changed over the last three decades, however the core values that GAP has achieved such success on, will continue to be instilled over the next 30 years. We look forward to the opportunity of working with our dedicated team to keep encouraging our customers to keep coming back to us time after time, through service, innovation and support.”

Double and triple glazed windows featuring highperformance glass from SaintGobain Glass will be put to the test in a unique £16m research facility designed to help create the energy efficient homes of the future.

Two full-size three-bedroom detached houses have been built inside the climatecontrolled chamber of Energy House 2.0 at the University of Salford, using the latest sustainable building materials and technologies. Over a period of nine months, the houses built by Saint-Gobain, Barratt Developments and Bellway Homes will undergo rigorous whole-building testing including thermal performance, energy efficiency, running costs and comfort, as well as their ability to cope with extreme climates, such as wind, rain and snow, and temperatures ranging from -20 to +40 degrees Celsius.

Usually, it would take months or years to collect the data needed to evaluate the performance of a new design or technology, but because researchers can precisely control the environment to within half a

degree, they can gather that data in a few weeks. That means that accurate results can be achieved quickly and accelerates the innovation process. In addition, the research will understand the impact of multiple technologies in the homes giving a better understanding of how the homes will perform in the real world.

Initially 1.2 Uw double-glazed, casement windows have been fitted into ehome2 by Barratt Homes. These will then be converted to 0.8 Uw triple-glazed casement windows by replacing the insulated glass units. The double and triple glazed windows feature Planitherm One T low-e coated glass from Saint-Gobain Glass and have been manufactured by Regency Glass, using the Eurocell Modus Window System fabricated by Nova Group and installed by New View.

Mike Butterick, Marketing Director at Saint-Gobain Glass said: “This is a collaborative project involving the entire supply chain and demonstrates that the existing UK window industry is ready and able to deliver the high-performance casement windows demanded by the Future Homes Standard 2025.

“Saint-Gobain Glass is at the forefront of innovation in the UK glass and window industry. High-performance glass has a critical role to play in delivering the fabricfirst solutions that other technologies rely

on for the creation of low-carbon, energy efficient homes.

“This ground-breaking laboratory will play a key role in accelerating progress towards large volume, low carbon and net zero houses that are sustainable, comfortable and will cost homeowners far less to heat and run at a time when we’re in the midst of an energy crisis.

“Saint-Gobain is leading the way by making a significant investment in this partnership with Barratt Homes to deliver this project, which also includes products from other Saint-Gobain group companies. This cutting-edge research will make a real difference to people’s lives and will result in a step-change in the way homes are built and used in the future.”

Oliver Novakovic, Technical & Innovation Director at Barratt Developments, said: “With the energy efficiency of the external

façades becoming ever more important, as we move to the 2025 Future Homes Standard, windows will play a critical role in meeting the regulations and delivering comfortable environments for our customers. EHome2 allows us to really understand the relationship between the façade, windows and heating solutions, which has not been considered to this level before.”

The built environment accounts for around 40% of the UK’s carbon footprint. The Future Homes Standard will require CO2 emissions produced by new homes to be 75-80% lower than those built to current standards. Homes will also need to be 'zero carbon ready', with no retrofit work required to benefit from the decarbonisation of the electricity grid and the electrification of heating. Energy House 2.0 is a £16 million project part-funded by the European Regional Development Fund.

Make Part L compliance a cinch with u-values as low as 1.0W/m2K! Save time on site with clip in beads – no wedge gasket Secured by Design options available across the complete

Leading arched frame supplier Premier Arches has rolled out nationwide delivery thanks to its own dedicated fleet of vans, ensuring not only the highest quality arched frames on the market, but access to the company’s services throughout the UK.

Managing Director Sean Greenall comments:

“At Premier Arches, we operate on three core principles – excellent manufacturing quality, outstanding customer service, and a ‘make life easier’ offering, and thanks to our own dedicated fleet of delivery vehicles, we’re able to deliver on all three, ensuring our customers can access our products no matter where they are in the UK.”

The new fleet follows a series of developments at Premier Arches, all of which have been designed to deliver the best service possible.

These include the introduction of a unique online pricing and ordering

platform which generates quotes within seconds, a specialist CAD Service which helps customers get a better idea of their arched frames before the manufacturing process, as well as the addition of Optima from Profile 22 to its wide product offering.

Premier Arches also recently invested in a new 2,000 square foot mezzanine floor at its St Helens facility, significantly ramping up production.

Sean continues: “We’ve been seeing increased demand for our arched frame products, and so we felt it was important to not only expand our premises in order to improve efficiency and turnaround times, but to invest in our own delivery fleet, enabling us to bring our products to fabricators across the country, and provide a full service from beginning to end.”

Established in 2015, Premier Arches manufactures and supplies arched, angled, gable,

circular and entirely bespoke windows and doors in a range of stocked systems, offering a full service to fabricators, trade counters, installers and local builders.

The company transforms the often daunting procedure of profile bending into a simple and pain-free process, saving fabricators time and money, and helping them win more lucrative projects which would otherwise be turned down.

For more information, visit www.premierarches.co.uk.

After winning the coveted Fabricator of the Year Award for the second time at last November’s G Awards ceremony, Yorkshire-based Quickslide might be after a further title of ‘Britain’s nicest window and door fabricator’ after showering its trade partners, suppliers and staff with gifts to celebrate and share its win.

No less than 80 customers, 20 business partners and all members of staff were given gifts including bubbles and vouchers, to join in with the celebrations: “We’re only as good as the people and businesses we associate ourselves with so in essence we wanted to say ‘thank you’ to everyone

for being a part of an award-winning team,” explained Quickslide Chairman Adrian Barraclough.

The latest trophy adds to the previous ‘Fabricator of the Year’ accolade, in addition to two others for specialist G Awards that Quickslide has won going back to 2011, and others the firm proudly displays in its ever-growing trophy cabinet: “We do love a good awards evening but as we couldn’t invite everyone along, we thought this would allow people to share in our celebrations. Not only do we make the best windows and doors, we know how to celebrate with our friends,” added Adrian.

www.quickslide.co.uk

TuffX has made a £500k investment to further grow its production by expanding into an adjoining unit at its Knowsley premises.

This expansion is in addition to an ongoing 30,000ft2 extension that is due to be completed by the end of this year.

“We need additional space to create more room for our popular Infinity rooflights production, as well as for our innovative Glow heated glass production,” said TuffX’s Commercial Director Paul Higgins.

Glow is TuffX’s thermostatically controlled toughened safety glass designed for bifolds. The glass is electrically heated to temperatures up to 40°C, providing a heat source for homes that will be in line with the Government’s drive to net zero.

“The Future Homes standards which will be coming in 2025 will stipulate the requirements for purely electrical heating sources to be installed in new homes in order to reduce carbon emissions,” said Paul.

“In light of this, we’re expanding our premises ready to accommodate this new and exciting production line for electrically heated glass. The additional space will also ensure we can maintain the steady growth in production of our Infinity rooflights and walk-on glass products.”

TuffX’s latest expansion is the company’s most recent step in what has been a consistent track record of investment in recent years, which has seen the leading glass specialist invest multi-millions in additional machinery, space and staff.

“The increased space will help us optimise our factory layout to best advantage, which will in turn boost our output,” said Paul.

“Our Infinity range continues to be popular among homeowners and installers not least thanks to its ‘straight from the box’ easy to fit installation. And now, with our additional focus on our heated glass Glow, we have the space we need to ensure we remain at the forefront of supplying the specialist glass products we know customers want.”

www.tuffxglass.co.uk

IMC

HERITAGE

An Edgetech customer has started to manufacture the only Super Spacer Heritage double-glazed units in Ireland which have passed BS EN 1279 Part 3. Based in Banbridge, County Down, IMC Glass is a leading specialist in heritage glazing, supplying customers throughout Ireland and the UK, and its Slim-Glaze units are particularly renowned throughout the market. The company’s high-performance Kryptonfilled double-glazing units start at just 11mm thick (about the diameter of a biro) and can fit into frames that were only designed for single glazing. They also meet the glazing requirements of properties which have listed status.

Passing the Part 3 standard, notoriously difficult for slimline units, is the latest example of the company’s commitment to excellence, as Director Aaron McCreanor explains: “Of the two parts of BS EN 1279, Part 2, which governs moisture penetration, is relatively straightforward to pass. Most manufacturers don’t have a problem with it. “Part 3, which governs gas leakage, is much harder. It’s extremely difficult to produce a unit that’s slim enough for heritage use, yet manages the required standard.

“At IMC, we’ve got an extremely talented technical team, and after a lot of hard work, they managed to produce units that consistently pass the test. We’re really proud to be the only company in Ireland to achieve this feat.”

Edgetech Head of Sales Tony Palmer comments: “We’re delighted with IMC’s Part 3 success using Super Spacer Heritage. Their technical expertise and commitment to excellence mean they’re constantly pushing the boundaries of what’s possible, and seeking to improve the products they provide. We look forward to working with them for many years to come.”

More information on IMC Glass can be found at their website www.imcglass.com. For more information, please call 02476 639931 or visit www.edgetechig.co.uk.

U-VALUE OF 1.2W/M2K – MEETS PART L NEWBUILD REQUIREMENTS DOUBLE-GLAZED!

U-VALUES OF AS LOW AS 0.8W/M2K TRIPLE GLAZED – FUTURE HOMES READY

KNOCK-IN GLAZING BEAD FOR RAPID INSTALLATION. SINGLE GLAZING BEAD ACROSS DECALU88 RANGE

PATENTED THERMAL BREAK

FLUSH INTERNALLY AND EXTERNALLY WITH EQUAL SIGHTLINES

MARINE-GRADE, METALLIC AND DUAL COLOUR FINISHES AS STANDARD

FULLY TESTED TO PAS24

PRE-INSERTED FLUSH FINISH GASKET FOR QUICKER FABRICATION

Lower stock holding. Maximum opportunity. Want to make more? Get in touch!

A family business with over 25 years in the window and door industry, Clear Windows & Conservatories(London), has joined the Steel Window Association to support the company’s diversification into the steel window and door market.

Since 1996, Clear Windows & Conservatories has manufactured uPVC products, with later expansion into timber, as well as aluminium, windows and doors.

George Pietrzycki, Company Director of Clear Windows & Conservatories explains “We are delighted to have joined the SWA and are looking forward to offering new and replacement interior/exterior installations of System W20 traditional design steel windows and doors, partitions, and room dividers/screens; including fire rated applications. The support and community we will enjoy as part of a leading association will prove invaluable to our new plans.”

For further information on the Steel Window Association, or if you’re interested in becoming a member, please visit www.steel-window-association.co.uk.

In an effort to become more environmentally conscious, leading bi-fold hardware supplier AT Precision has introduced a new Recycled Thermal Reinforcement (RTR) system to its production line, thanks to a new in-house recycling scheme at its Durham-based premises.

The new recycling scheme sees AT Precision picking up unused or unwanted uPVC materials from its customers, and processing these for use in manufacturing its own screw retention profile bars.

Sales Director Michael Hewitt explains: “We’ve found that many of our customers are left with unused materials following their production processes, so we’ve introduced our new recycling scheme to ensure that nothing goes to waste.

“Our customers are encouraged to contact us when they have unused uPVC materials to get rid of – we will then collect these and pay them the value of the materials. Once the materials have been collected, we grind and melt them down to produce a screw retention profile bar.

“With the climate crisis dominating headlines, making efforts to become more sustainable has been a priority for many in the fenestration sector. At AT Precision, we have a commitment to playing our part in helping the planet, and we feel the new recycling scheme and RTR system have been very worthwhile investments.

“Our new recycling scheme has not only added an additional 10,000 square feet to our manufacturing facility, but also makes us a more sustainable company, while the RTR system provides benefits to both the environment and our customers, such as improved thermal efficiency, quick installation, and a minimum lifespan of 35 years.

“AT Precision has a reputation for providing high-quality, affordable hardware solutions across the country – now, with a new commitment to reducing our carbon footprint, we can not only be the reliable supplier that our customers can rely on, but a sustainable company that prioritises our planet.”

Visit www.atprecision.co.uk.

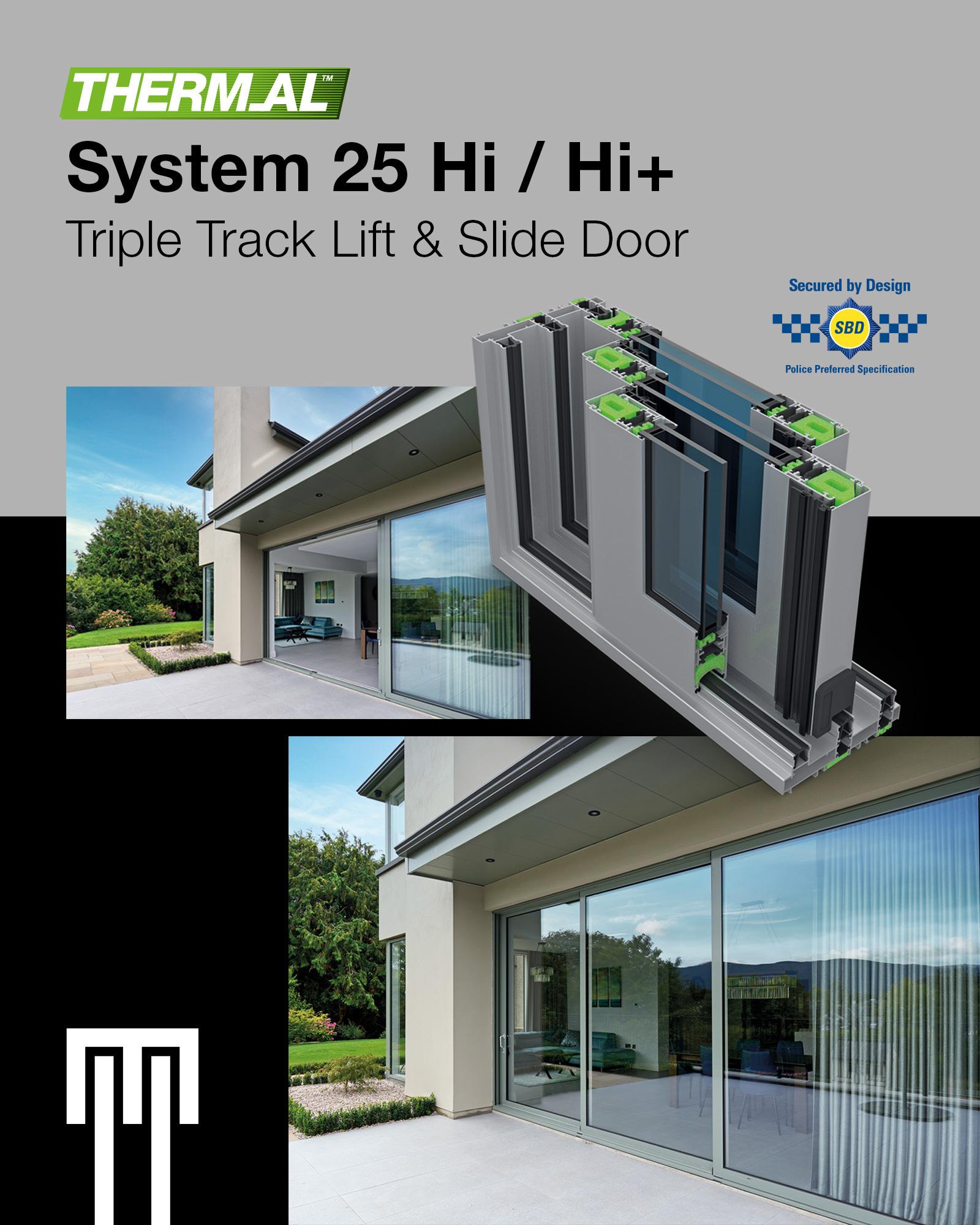

Sheerline has enhanced its popular Prestige range by adding a new thermally efficient Lift & Slide Patio Door, ready to transform any space. Its’ super slim sightlines of 106mm (frame and sash) maximise the views in any room and it offers highperformance U-values of 1.4 with double glazing and 1.0 for triple glazing. These U-values are easy to remember as they are the same for every product within the Prestige range and have been achieved thanks to Sheerline’s proprietary Thermlock® technology. It’s a huge achievement for the team and further highlights Sheerline’s commitment to innovative, energy efficient products that don’t compromise on sustainability, security, or style.

A key feature of the new Lift & Slide Patio Door is the fact it perfectly matches Sheerline’s other products so homeowners can achieve a consistent aesthetic throughout a project. However, fabricators and installers also benefit from the consistency provided by Sheerline’s technical team.

For instance, the Prestige Lift & Slide Patio Door integrates seamlessly with other products as it utilises Sheerline’s proven clip-in bead system. In addition, it’s available in Sheerline’s signature stepped sash, a range contemporary colours, is Part L compliant (as standard) and can be ordered up to a maximum size of 6.5m wide and 2.5m high, with up to 400kg sashes.

The Prestige Lift & Slide Patio Door completes the Prestige door range, meaning that Sheerline fabricators can now offer a matching suited range of proven products that integrate seamlessly.

Installers will also appreciate the different threshold styles available. This includes the standard outer frame, a version with a clip-on cill nose, alongside a ramped low threshold, which has been tested in-line with Part M requirements. There’s also a concealed zero threshold available, which is ideal for sheltered

locations on projects looking for a seamless transition between spaces.

As with all Sheerline products, the Prestige Lift & Slide Patio Door has been designed to offer high levels of security as standard, featuring a unique retracting hook-lock with flush keeps. Which reduces the risk of snagging clothing on protruding pegs. The doors glide smoothly during operation because of the specially designed stainlesssteel tracks and high-performance running gear. Dual and triple track options are available, which cover most requirements. To enhance the Prestige Lift & Slide Patio Door, a patented sealing system has been incorporated to ensure the doors are weathertight against the worst of the UK’s weather.

Considerable design consideration was also given to ensuring interlocks were as slim as possible, while also maintaining the systems exceptional thermal credentials. The new Sheerline patio comes with a choice of standard interlocks with slim 80mm sightlines, as well as ultra-slim 52mm interlocks suitable for use on many popular styles.

Sheerline’s Product Design Director, Adrian Redshaw comments: “We’re really proud of our new Prestige Lift & Slide Patio Door because it completes our Prestige range without compromising on the features that are most important to our customers; super slim sightlines, exceptional thermal efficiency, and looks that match all our other products.”

“These are the features that elevate this product, and the Prestige range, to the next level, especially when compared to other products on the market. We’re helping homeowners achieve their dream aesthetic that integrates stylish interiors with beautiful outdoor spaces without compromises,” he added.

View the Prestige range in full by visiting the website: http://www.sheerline.com, or to speak to the team directly, email: info@sheerline.com

Freefoam’s comprehensive range of stunning, easy to install, unique cladding transforms the look and insulation value of a home. No wonder homeowners smile at Freefoam installers’ stunning transformations.

Different ages of the UK’s built heritage are frequently most recognisable from their fenestration patterns as by their roof structure or choice of walling materialsmaking decisions regarding the windows replacement or conservation critical to the overall success of any redevelopment.

So it is that London-based Associated Steel Window Services (ASWS) has built a solid reputation far beyond the capital for successfully undertaking some of the most challenging fenestration contracts. ASWS worked in close cooperation with the project’s lead design consultants; as well as coordinating its operations with the main and other contractors. In fact, the multigenerational expertise ASWS offers extends beyond its management team to many of its long-serving workforce; while the company also retains a vast library of ironmongery and other window and door components, together with an established supply chain to keep contracts on track.

“ASWS was involved from beginning to end and they were exceptionally helpful, working assiduously right the way through the project. We were very pleased with their proactive approach. From my point of view, they have done remarkably well and came up with the goods; I’m very happy with the result and would certainly go back to them.”

David Loxton – Loxton & Associates (Project –Alexandra House)

Managing Director, Kris Bennell, explains:

“As a family business with a long track record within the industry, we are respected for our experience and try to offer added value for architects and the other professionals we deal with; often on a regular basis. In fact, we are frequently brought on board at an early stage to conduct very detailed condition surveys, and to offer ideas on how conservation goals can be achieved. Which then becomes part of the negotiation with the planning authorities.”

“There has also been a shift in the way projects are run, with end clients now actively encouraging architects to engage with specialists like ourselves – especially where the main contractor is leading the work. This can include them making use of our enablement service: where we can remove heritage fabric and windows to facilitate access for hoists or chutes, as well as cataloguing and putting frames and other components of historical value into safe storage for the duration.”

“We relied on ASWS as specialists to tell us what could and couldn’t be repaired. They were incredibly knowledgeable and their expertise was helpful in understanding what needed to be done with the windows.”

Andrew Morgan – JM Architects (Project - Heals Building)

Amongst the many historic buildings where ASWS has provided its unique skillset are Woolwich Arsenal, the South Bank’s County Hall building, The Royal Academy of Arts, the iconic retail emporium Whiteleys and the recently redeveloped Battersea Power Station. Both the Royal Academy and award-winning renovation work on one of the Crown Estate’s most public propertiesQuadrant Arcade, on Regent Street - both saw the specialist offering advice to the leading architectural practice, Barr Gazetas.

“We regularly use ASWS and the project went really well. The initial schedule of work that they produced was incredibly useful and detailed. It was quite a tricky project for them and they did a good job, especially considering the budgetary constraints and number of windows involved. Their advice and expertise were very helpful, especially with the ironmongery.”

Karen Fuller – Barr Gazetas (Project – Glasshouse and multiple other projects)

For more information on ASWS, please visit asws.co.uk.

ISO Chemie’s multi-functional joint sealing tape ISO-BLOCO Hybratec is now available as stock in a move to meet demand for energy efficient window sealing solutions and product availability from UK installers and specifiers.

ISO-BLOCO Hybratec is a window joint tape featuring the latest in hybrid technology to provide effective three-level 100% air tight sealing in line with RAL energy performance standards and resistance to driving rain in excess of 1050 Pa.

The tape, which also complies with the energy efficiency requirements of the Building Energy Act, provides excellent air tightness and thermal protection when it comes to the sealing between the inner room and external climate. Uncontrolled convection heat losses and draughts via the connection joint can be effectively eliminated - an important requirement in energy-saving construction.

ISO-BLOCO Hybratec also combines considerable expansion force with excellent functional reliability in terms of capacity to absorb long term movement and expansion of windows.

Awarded the ‘Certified Passive House Component’ label by Germany’s Passivhaus Institute, the tape can officially be used in the construction of passive energy houses across the UK as a window connection air tightness system.

In passive house construction, it is important for a building to be extremely air tight to minimise heat input required to warm the house, said Andy Swift, ISO Chemie’s sales and operations manager, who said the company is investing in UK stock handling and distribution to improve services and meet demand.

He said: “ISO-Chemie has a strong commitment to providing customers with high quality innovative products, so its good news for specifiers and installers that product, which offers outstanding thermal values esnure its advantages for passive energy installations, is now available as UK stock.”

Passivhaus-certified products provide high energy savings combined with enhanced comfort compared to conventional newbuilds and renovated properties. This requires the use of particularly energyefficient components, in addition to careful and detailed planning.

As an independent body, the Passivhaus Institute in Darmstadt tests and certifies products with respect to their suitability for use in passive energy houses. Products bearing the ‘Certified component’ quality seal have been tested against standardised criteria, have comparable characteristic values and offer excellent thermal quality.

ISO-CHEMIE is one of Europe’s main producers of impregnated foam sealants, specialising in the manufacturer of foam products from polyethylene (EPE), polypropylene (EPP) and polyurethane (PUR) using the latest production techniques.

www.iso-chemie.eu/en-GB/home/

Marking another step towards a purely authentic REHAU window solution, we have expanded our offering to include a range of window finishing trims in a select range of standard and niche colours including turner oak, elephant grey and midnight black.

Windows. Reinvented for modern life. rehau.uk/trims enquiries@rehau.com Tel: 01989 762600

Epwin Window Systems has just published its new commercial guide for its multiple PVC-U systems. Gerald Allen, Head of Marketing at Epwin Window Systems, said: “Our new commercial guide showcases the depth and breadth of our PVC-U commercial offer. It will help our fabricator and installer customers to demonstrate the added value they are able to deliver to commercial contractors and specifiers.”

The 56-page brochure perfectly showcases Epwin Window Systems’ commercial credentials, including a 17% market share and products that have been specified and installed in millions of homes, schools, colleges, student accommodation blocks, hospitals and other commercial buildings.

The well-designed brochure looks at the advantages of Epwin Window Systems products, including unparalleled design flexibility, industry-leading security, impressive thermal efficiency, futureproofed performance, exceptional quality assurance credentials and a commitment to sustainability.

There’s an introduction to the complementary internal design support service, which gives commercial contractors access to technical expertise and practical support to ensure they meet the exacting standards on every aspect of their window and door schedule.

Contractors can also read about the benefits of the Approved Commercial Partner scheme, which provides peace of mind that a project is being manufactured and installed by reputable commercial contractors.

The main section of the brochure introduces the multiple PVC-U window and systems in the Epwin Window Systems vast portfolio. This includes the Optima Casement, Spectus Casement, Flush Casement, Optima Tilt & Turn, Spectus Tilt & Turn, Flush Tilt & Turn, Fully Reversible Window and the Vertical Sliding Sash Window. For door systems, it includes the Optima Door, Spectus Door, PatioMaster Sliding Patio Door and the Emergency Door NSHEV and (AOV) window.

There is also information on the popular Curtain Walling System and the Two-Part Cill.

Sections on hardware and the cutting-edge Colour Collection are showcased and the comprehensive brochure closes with a series of commercial case studies that demonstrate the transformational benefits of choosing Epwin Window Systems products.

Gerald concluded: “Overall, the brochure demonstrates the unrivalled technical and specification support, industry expertise and in-depth knowledge of contracts and building regulations on offer from Epwin Window Systems. In other words, everything you would expect from an experienced commercial systems partner.”

The new commercial guide is available to download from the Connect digital portal.

Tel: 0845 340 3968 – www.epwinwindowsystems.co.uk

An agreement between leading VEKA and Halo window and door fabricator Glazerite UK Group Ltd and VEKA Recycling Ltd, for all virgin offcut material and limited volumes of post-consumer frames to be collected and recycled, has created a perfect model of the ideal window industry circular economy arrangement.

Following a highly successful launch at last year’s FIT Show and a year of establishing a nationwide dealer network, GERDA Residential Doors has launched a brand-new UK specific website through which British homeowners can specify products developed specifically for the UK market.

Pioneer Trading, exclusive distributor for Gerda in the UK, used the FIT Show to launch the range of Gerda unique steel and aluminium front entrance doors. Stylish, elegant and with an emphasis on high security with superior thermal performance across all of its products, Gerda Doors are superbly engineered using the finest steel and aluminium door construction techniques. With high performance levels and unique construction methods and materials, Gerda Doors are an effective alternative to conventional composite doors. The website – www.gerdadoors.co.uk – offers details of the four key ranges available –Optima, Thermo Premium, Thermo Prime and Altus – and describes each in detail including handles and hardware. A Q&A section offers homeowners advice on Gerda and particularly, why Gerda Doors are different from any other brand of residential door currently available in the UK.

An extensive photo gallery offers examples to guide homeowners, following which they may find their local Gerda dealer.

Tel: 01245 362236 - www.gerdadoors.co.uk.

The deal sees virgin offcuts from Glazerite’s Wellingborough, Peterborough and Bolton manufacturing operations, in addition to frames removed from selected installation sites, collected and returned to VEKA Recycling’s advanced PVC-U reprocessing facility in Wellingborough. With VEKA PLC’s Burnley extrusion facility now a large volume user of recycled pellet from its sister organisation, much of the material returned from Glazerite may be returned to them in the form of brand-new profiles to again be manufactured as new windows and doors.

Darren Rhodes, managing director of Glazerite’s North West Division, led the negotiations for the new contract: “Inevitably there are offcuts from the production of new frames despite Glazerite using advanced manufacturing techniques throughout our facilities, but this material remains intrinsically valuable. We also have agreements on a number of installation sites for which we support installer customers, by removing old frames from site.

“VEKA Recycling has provided a solution for Glazerite and a number of

our customers, by efficiently removing the material through bins placed at our sites. This reduces disposal costs and contributes significantly to Glazerite’s commitment to reducing the company’s carbon footprint. It also enables us to support our customers by providing recycling facilities, now a commitment demanded by public sector and larger landlords for refurbishment projects,” added Darren. Collection bins are placed at Glazerite’s factories and at sites such as the eightstorey housing project being installed for Warrington Borough Council housing by Glazerite customer K2 Aluminium Systems, from where they are returned directly to VEKA Recycling’s Wellingborough site for immediate reprocessing. The reprocessed PVC-U Pellet is 100% quality inspected to specification and ready to be extruded into new products such as ducting for air conditioning and electrical cabling, and new window and door frames such as at sister company VEKA PLC, Glazerite’s principle system supplier.

VEKA Recycling managing director Stuart Stockley says that the Wellingborough facility reduces carbon both through its processes and its location: “We have the most advanced PVC-U recycling facility in Europe which produces the highest quality PVC-U pellet, whilst our central location also contributes towards carbon reduction by ensuring all processes are completed within the UK. The loop between extrusion, through fabrication, installation, recycling and back to extrusion again, is perfected by this arrangement, and one that we will work towards repeating.”

the only clip-bead that delivers glazing and de-glazing in seconds.

IMPROVED for a faster install NEC BIRMINGHAM 23 - 25 MAY 20 23

PRE-FITTED

STAND Q11 QUALITY CHECKED PASS

PAS24

Pre-hung

Jon, who joined GAP originally in 1996, will undertake the newly created role of Procurement Director, effective immediately.

Low maintenance trade specialists, GAP are delighted to announce that Jon Randles has joined the companies’ growing board of directors, after having previously served in a number of roles for the company, most recently as Group Purchasing Manager.

Jon’s promotion comes at a crucial point in GAP’s history, as the company celebrates their 30th anniversary in February this year, with a number of further and exciting growth and expansion plans due to tie in with the landmark celebration.

Speaking of his appointment, Jon reflects on his time so far with GAP and how he is already making headway in his new role:

“I’m honoured to have been appointed to GAP’s experienced board of directors. Having first joined back in 1996, starting at our original Liverpool depot, I would never have thought that I’d be where I am now, and I’m truly delighted to be here in this new role.

“Jon has spent a very large part of his working life with us at GAP, so welcoming him to our board not only strengthens our team, but it also adds years’ worth of crucial, in-depth understanding of the building plastics industry, alongside expert product and market knowledge.”

“We have so many exciting plans ahead for the year, and I am looking forward to contributing further to the wider company and the growth plans we have in place over the next 12 months and beyond.”

Joint MD, Charles Greensmith believes the addition of Jon to the board of directors will provide more than just valuable experience:

“Jon has spent a very large part of his working life with us at GAP, so welcoming him to our board not only strengthens

our team, but it also adds years’ worth of crucial, in-depth understanding of the building plastics industry, alongside expert product and market knowledge.”

After the company reported strong sales growth last year, originating from numerous depot openings and multiple new product lines such as HomeFrame GRP Composite Doors, Jon finds himself joining the board at an exciting time as they look to the future.

A Supreme Court decision that residents have a right to privacy even when their homes are overlooked should spark industry conversations about smart shading technologies, says an industry expert.

The court’s findings that flat owners opposite the Tate Modern’s viewing gallery faced an unacceptable level of intrusion into their homes could potentially have a significant impact on the fenestration sector, according to Russell Hand, Head of Product Management and Technical at REHAU. He made the comments following the court’s determination that flat owners faced ‘constant visual intrusion’ that impacted their ‘ordinary use and enjoyment’ of their properties.

“The need for privacy may fundamentally change how windows and accessories are selected in builtup areas where space is increasingly at a premium, especially for flats and apartments.”

Specifically, Russell drew attention to the upheaval the decision could cause on window specification for installers working in densely populated urban environments on retrofit or newbuild projects. He said: “While the findings have extended the law of privacy to include overlooking in only extreme cases, those involved in the specification process should be vigilant to further challenges that could loosen this criteria.

“The need for privacy may fundamentally change how windows and accessories are selected in built-up areas where space is increasingly at a premium, especially for flats and apartments. Being overlooked may be unavoidable for residents in certain situations, so installers need to plan accordingly by looking into smart privacy technology options that can be implemented into frames.”

Shading solutions have grown in prominence in the windows sector, with suppliers such as REHAU continuing to develop its Smart Privacy solution. Russell believes that the technology, which can make full windows transparent or nontransparent at the push of a button, could provide a solution to the issue arising from overlooked properties.

“Though shading is still in its infancy as a solution, the possibilities the technology presents are very exciting for the industry,” Russell concludes. “Our own option, Smart Privacy, will be the first of its kind to be able to be produced industrially for implementation on residential and commercial properties.

“From talking to the market, we know that occupants don’t always want the classic curtain or blind option, and permanent milky films may not be appropriate as they can block the residents’ view. Controlling visibility through an app or controller therefore looks like the best possible privacy option, and we would encourage fabricators and installers to look out for this technology in the future.”

For more information, visit: www.rehau.com/uk-en/smart-privacy-from-rehau

Installing Granada Glazing’s secondary glazing system has delivered a significant saving in energy costs for a North Derbyshire welfare centre by reducing heating needs by two thirds, as well as eliminating external noise intrusion.

All the windows at the Muslim Welfare Association’s Grade II listed building in Chesterfield are original and single glazed, which provided little thermal insulation for users of the facility and allowed noise from a neighbouring factory to enter the rooms.

The building’s owner contacted Bakewellbased Brocklehurst Property Maintenance Ltd, one of Granada Glazing’s trade partners to discuss options, suitable treatments and fit a total of 59 units.

A combination of horizontal sliding units and arched units were installed. All have Low-E glass with a special coating that reflects heat back into the rooms as the main aim was to make the building warmer. Some windows feature an arched unit stacked over a horizontal sliding unit, while

others were treated with two horizontal sliding units one above the other.

Superior thermal insulation provided by quality secondary glazing reduces heat loss by up to 70%. Far less expensive than full window replacement, secondary glazing is often the only option to improve thermal efficiency in historic or listed properties.

Duncan Brocklehurst, Managing Director of conservation and renovation specialists

Brocklehurst Property Maintenance explains: “We were approached initially by the property owner to help keep the building warm in the face of rising energy bills. The building is listed and its old, steel windows were simply not performing either thermally or acoustically. In addition to the issues around heat retention, the customer was also experiencing excessive levels of external noise from a nearby factory, which proved particularly challenging during prayer sessions.

“The products that Granada supplied have ultimately helped to rectify both issues. The

Leading Birmingham window and door manufacturer

Shelforce has invested in a new software system from First Degree Systems.

The company, which specialises in providing high-quality PVCu and aluminium products, including fire doors, to local authority building projects has made the move due to continued success and rising demand.

Its fully compliant Fireshel 30-minure fire, smoke and security resistant door, which Shelforce launched in 2020, has proved so popular that the Erdington-based company now manufacturers 200 doors a week.

Shelforce’s Business manager Howard Trotter said: “Upgrading our software system to a cloud based one is crucial moving

forward due to demand and our business success. As we have grown we have had more orders to process and deliveries to send out and we need that information available at the push of a button.

“The new system will improve our processing power, bring us greater procurement control, and make things more efficient in terms of quoting, customer orders, ordering raw materials, production control and confirming work and converting it into orders.

“It will also incorporate and help organise weekly product and delivery schedules and it will be great to have everything in one system and under one umbrella.”

Shelforce is also looking at putting a new phone system in place that will be production friendly for staff on the shop floor, and Howard added: “It’s all about increasing efficiency and our business growth has enabled us to invest in these new software systems. Things will take minutes rather than a day, which will help our customer service as demand increases.”

To find out more, call Shelforce on 0121 603 5262 or visit www.shelforce.com.

factory noise is now not noticeable at all, and the customer is able to run their heating for just one third the amount of time they were previously. It’s been a massive financial saving.”

Ellen Dawson, Trade Sales Office Manager at Granada Secondary Glazing comments: “Given the requirements from a thermal perspective, we opted for a 4mm toughened Low E glazing solution that would drastically improve the building’s heat retentive properties.

“Where possible, we specified bespoke, arched units to match the primary windows exactly. Where this wasn’t possible, we instead stacked horizontal units on top of one another. Our entire suite of products offers incredible thermal and acoustic performance; it’s fantastic to hear that the customer has been reaping the benefits of the install so quickly.”

Suitable for all property types, Granada’s slimline aluminium secondary glazing frames can be powder coated in over 200 RAL colours. Virtually invisible, they blend in with any interior décor. The Granada Glazing product range encompasses hinged, sliding, vertical sliders, including tilt back, and lift-out options. Full training and marketing support is available to installers across the UK.

For more information about adding the Granada Secondary Glazing range to your business, please call 01909 499899, visit www.gsecg.com or email info@granadaglazing.com.

Epwin Window Systems has published a new sustainability brochure that highlights its environmental commitments throughout the business.

Phil Parry, Business Development Director, said: “Here at Epwin Window Systems, sustainability is front and centre across all our business practices. It’s not only the responsible thing to do, but there are clear commercial advantages too because end users increasingly prioritise sustainability in their purchasing decisions.”

The eight-page brochure highlights Epwin Window Systems’ cradle-to-cradle approach to the sustainability of its multiple systems.

Epwin Window Systems is the only UK-based PVC-U systems company certified to the requirements of BES 6001: Issue 3.0. This demonstrates the company has ensured – and can prove – that its products have been made with constituent materials that have been responsibly sourced.

As further evidence of its sustainability commitment, it was the first UK-based systems company to achieve the VinylPlus® Product Label, the scheme that makes it easy for customers and markets to identify the most sustainable and high-performance PVC-U products.

The company has a zero to landfill policy. Waste management processes are designed to segregate waste at source and all waste from its site is segregated and

sent by registered waste carriers for recycling. Waste bar lengths are recycled into RCM (recycled composite material) for use in thermal inserts for outerframes, sashes, transoms and mullions.

In use, all Epwin Window Systems products have been designed to maximise thermal efficiency and meet and exceed regulatory requirements. This helps specifiers, contractors, fabricators and installers to meet environmental targets – and give end users low maintenance products that help create thermally efficient homes.

Epwin Group has recently acquired the British company Poly-Pure Ltd, a leading recycler of post-consumer PVC-U window and door frames. The acquisition means it can take PVC-

U window and door frames at the end of their useful life, recycle the PVC-U content, and incorporate the reclaimed material back into new extruded building products manufactured across the Group. Phil said:

“This latest Group acquisition fully closes the recycling loop to cover the complete product lifecycle. Plus, like us, Poly-Pure is a UK based company, which means we can proudly say our products are made (and fully recycled) in Britain.”

Phil concluded: “We have a long track record of commitment to the environment. Back in 2009 we were the first UK systems company to offer a 100% recycled window. But our progress to date is just the start. We have well-developed and impactful programmes in place to continue to reduce our carbon footprint and enhance sustainability across all our activities, products and processes. We have aligned our operations to the United Nations Sustainable Development Goals and are developing an Environmental Social Governance framework and targets. In short, here at Epwin Window Systems we’ve made a commitment to a greener tomorrow.”

The new sustainability brochure is available to download from the company’s Connect digital portal.

Tel: 0845 340 3968 – www.epwinwindowsystems.co.uk

Contech Conservatory Roofing Ltd is a customer oriented business that has a long-standing working relationship with Kolorseal on coloured roofing projects. Based in Stoke on Trent, the company prides itself on offering tailored solutions to meet the needs of an ever changing market.

The Kolorseal team fully understands the need to provide choice and quality standards for Contech customers when colour is specified. The two companies work together to provide high calibre solutions and excellent customer service for the end user, particularly as demand for coloured products is increasing.

Over the years, Gareth Jones, Managing Director at Contech Conservatories has noticed how colour is being used more frequently to create striking finishes and powerful messages on projects, particularly if this requires something a little out of the ordinary.

He comments, “The use of colour is becoming even more important on modern projects as end users know they can add their own personal style to a home or commercial building. As a company we want to ensure we can give as broad a choice as possible which is where Kolorseal excels.”

Matching corporate colours on projects is nothing new for both teams and this can be shown on the complete refurbishment of a prestige car company’s head office, near Stoke. There was an important stipulation on the project that colour matching was essential as everything had been rebranded and things needed to be kept commensurate. Bifold doors, windows and guttering were required externally and internally to match the company logo in a dark green shade.

Gareth Jones, Director, Contech Conservatory Roofing Ltd comments, “The entire project was manufactured according to the exact specification of our customer and the business owners wishes for this extremely high specification job.”

He concludes, “This particular combination worked a treat and it provides a contemporary feel with a classic finish that the end user has been thrilled with since the installation was completed.”

When looking at corporate colour matching Deborah Hendry, Managing Director at Kolorseal comments, “ When matching colours for business such as this, it is important that the tone will also complement the style of the original building.

On any colour spraying contract we always work with our customers to ensure that the correct shades can be matched exactly - we understand the importance of this particularly when replicating a company’s colour brand, which could fade in time if not sprayed properly. We have many options for customers to choose from from RAL charts through to Farrow and Ball and beyond.”

For more information on the products and services available from Kolorseal please visit www.kolorseal.co.uk or call 01924 454 856 to discuss colour coating requirements. For Contech Conservatory Roofing Ltd please visit the website www.contechconservatories. co.uk or call 01782 593 968.

Debar has further expanded its portfolio of bi-fold hardware products with the launch of a brandnew line of contemporary and modern bi-fold door handles.

Velté is a sleek and minimalist range of handles which is suitable for most intermediate bi-fold door locking panels. Plus, with its modern, clean and seamless appearance the handles add a touch of elegance to any home’s bi-fold door system. Developing quality products is a huge priority for the leading Bradford-based bifold manufacturer and so the team has specially designed these handles so they not only look aesthetically excellent but are also highperforming.

All screws are concealed by a patent pending aesthetic plate to create a seamless clean look for the homeowner, while also boasting a unique anti-rotating innovation to deliver extra security by ensuring that the handle remains in place and cannot be tampered with by unauthorised persons – giving homeowners true peace of mind.

With three different choices available within the range, the Velté handles offer a variety of options for homeowners. One of which includes a landmark product which is the company's first handle that includes an impressive integrated cylinder.

Debar also offers a standard handle and a handle that features an escutcheon for an 18mm Euro cylinder. The handle tilts outwards for easy operation and is completely flat when not in use, making it the perfect addition to any home.

Constructed from zinc die cast and steel spindle, these robust handles fit on gearboxes or shoot bolt locks with 7mm spindle and 43

As part of its external affairs strategy, Glazpart has joined the British Plastics Federation (BPF).

With the trading environment adapting to legislative and policy changes made earlier this year, Glazpart felt it essential to have a voice in discussions with the BPF and its member companies in the plastics manufacturing and supply chain to the construction sector.

screw centres, such as the innovative Debar Robus Locks.

Andrew Fawthrop, National Sales Manager, at Debar said: “We’re delighted to further expand our comprehensive range of quality bi-fold locks and handles, with the launch of Velté. Whether you’re looking for a handle that prioritises security, or one that emphasises style, the Velté range of handles has you covered.

“These modern and sleek handles not only look great but are also incredibly hardwearing and use a specialist anti-rotating design to deliver fantastic protection and security. The Velté range is a great fit for any bi-fold door system and will no doubt be a must-have product for fabricators, installers and homeowners alike.”

Debar is the largest independent British manufacturer of bi-fold hardware and bi-fold door systems, supplying to fabricators and system houses around the world.

For more information on the brand-new Velté handle range contact the Debar team today by emailing sales@bifold-hardware.com or calling 01274 673 547.

BPF is the world’s longest established plastics trade association and has more than 450 member companies, representing over 80% of the UK plastics industry by turnover. On joining the BPF Moulders Group, Dean Bradley, Glazpart Sales Director commented,

“Whilst the Moulders Group offers to opportunity to network and understand wider industrial markets, whilst being part of the wider industry discussions impacting the plastics markets.”

In addition, to being part of the Moulders Group, Glazpart also intend to have an input to the BPF Windows Group. Dean Bradley explains,

“As the regulatory landscape has changed and continues to evolve, we see a clear need to present our concerns to key influencers in the plastics sector. We look forward to taking part in future meetings to discuss the impact of the changes to the Building Regulations, “Approved Document F” regarding ventilation in homes.”

The revised “Approved Document F” aims to improve the standards concerning energy efficiency and air quality of a building. The amendments have also been designed to ensure that ventilation is not compromised in the drive to the Government’s net zero targets, which aim to prevent energy loss from residential properties and minimise potential overheating risks.

This uplift in standards is expected to be followed by the planned introduction of the Future Homes Standard in 2025. The standard is set to be the subject of a government consultation in 2023. www.glazpart.com

Trade fabricator Modplan has just completed a new manufacturing extension at its headquarters in Newport, Gwent. The new extension further boosts Modplan’s manufacturing capacity across its multisite operation and will accommodate the company’s doorline fabrication.

Heidi Sachs, Modplan’s Managing Director, said: “We firmly believe in continuous investment in our business. This new doorline extension will open up new opportunities and provide additional capacity to support our long-term growth efforts.”

The new extension will allow Modplan to maintain its competitive turnaround times even as volumes increase. The extension has been future-proofed too, because new fabrication stations can be added as volumes grow further.

As you would expect from a Modplan facility, the new manufacturing centre is equipped with state-of-the-art door fabrication machinery, including a dedicated automated supercut machine for precision accuracy.

Heidi commented: “Investing in machine technology helps us deliver the quality we want as well as maintain competitive turnaround times, even as we grow.”

As Heidi says, continuous investment is a priority for Modplan. The new door extension follows hot on the heels of investment in several new trucks for its transport fleet as well as increased capacity to support the growth in demand for its PVC-U Flush Sash windows. It has also opened a Training Academy, which provides a dedicated space to train personnel across its business from NVQ level through to management. As well as supporting its own staff, the Training Academy is also available to Modplan’s customers, offering both office-based skills development and handson fabrication training.

Modplan manufactures a wide range of window, door and conservatory products for it growing customer base. It also has a partnership approach that delivers marketing, technical and training support that adds value to an installer’s business. Add in a clear commitment to continuous investment to ensure it is equipped to continue to deliver for its customers both now and into the future and it becomes clear why the company is about to celebrate 50 years in business.

Tel: 01495 246844 – www.modplan.co.uk

Endurance Doors® - the designer and manufacturer of solid, secure, and stylish composite doors - has invested over £300,000 into 500 solar panels which have been installed on the roof of its main production facility in Brigg, North Lincolnshire.

The new panels build on an existing focus at Endurance Doors of only using electricity generated from renewable sources, rather than fossil fuels, throughout its manufacturing processes. They will also significantly reduce the company’s energy spend.

Stephen Nadin, managing director at Endurance Doors, said: “As a business, Endurance Doors is proud to be a leading advocate and adopter of more sustainable manufacturing practices for the fenestration and construction sectors.

“To date, we have made enormous strides in our drive to minimise our environmental impact but there is no room for complacency. We continue to look for new opportunities to increase our levels of sustainability and the installation of the solar panels at our Brigg factory reflects this relentless focus.”

The use of self-generated electricity from solar energy is just the latest in a long line of steps taken by Endurance Doors as part of its commitment to the environment.

The business already plants two trees for every door it produces, sends zero waste to landfill, employs recycled material where possible, and aims to use virgin material from renewable, sustainably managed sources such as PEFC (Programme for the Endorsement of Forest Certification) and FSC (Forest Stewardship Council) certified forests.

Endurance Doors® has also became a corporate supporter of the World Land Trust (WLT) – an international conservation charity whose patrons include Sir David Attenborough, Chris Packham, and Steve Backshall.

“At Endurance Doors, we recognise our responsibility and the need for action rather than words. Anyone who buys our products can be confident they’ve been designed and manufactured with the future of the planet, as well as security and style, uppermost in mind.”

-Stephen Nadin, Managing Director,Endurance DoorsBy partnering with the WLT, Endurance Doors has become carbon neutral with any unavoidable emissions from its operations being offset by investment into forests, biomass plantations and other sustainable means of carbon sequestration.

Concluding, Stephen adds: “The next decade is make or break when it comes to the environmental issues facing the Earth. In the last 12 months alone, we’ve seen stark evidence of the effects of climate change – from record-breaking unseasonal heatwaves to devastating floods.

“At Endurance Doors, we recognise our responsibility and the need for action rather than words. Anyone who buys our products can be confident they’ve been designed and manufactured with the future of the planet, as well as security and style, uppermost in mind.”

Manufacturing more than 3500 PVC panels and 500 composite doors per week for a national network of over 1800 installers requires a constant and reliable delivery service.

That’s why Hurst Doors has heavily invested in their own dedicated fleet of 24 Mercedes vans and to support the large transport operation. Each van travels around 100,000 miles a year to help deliver more than 200,000 door products nationwide and Hurst’s Sales Director, Mark Atkinson, said: “When you’re sending approximately 4,000 products out every week, you want to know that they’re going to arrive on time and safely with the customer. Having our own transport fleet gives us this control over distribution and is a real benefit both to our customers and the business.

“We used to outsource to a third-party delivery company many years ago however now we don’t have to rely on couriers for 95% of our deliveries, which minimises damages, provides traceability, and gives us complete control.

“Our fantastic Transport Manager, Jon Brake, who has been with the company 18 years, organises deliveries nationwide from our manufacturing facility in Hull. It’s a big operation and is cited by customers as a USP for Hurst; time is a precious commodity, and we understand how important it is to customers for deliveries to be made on time and in full. Thanks to our transport fleet and wider distribution capability we can provide that service across the whole of the UK.”

Hurst’s distribution has been helped by a recent £200K

investment in a new 430sqm extension to its 50K sq ft manufacturing facility in Hull. This has enabled the business to provide a greater consistency of service in its dispatch of PVC panels and composite doors. The extension features a dedicated loading area for the fleet of 24 vans to be loaded overnight ready for the next day.

“As the fleet doubled in size, space became very limited. The extension has provided more space for the vans to reversed into the loading area meaning we can load them more efficiently and effectively,” explained Mark.

“We have built our reputation on our OTIF, which is currently at 99.8% on panels and 97% on composites. This investment will make it easier to achieve our 99.9% targets and reassure customers that we are doing everything we can to increase and ensure consistency of service.”

Customers can track their deliveries through Hurst’s online support portal, Hurst Live, which enables them to manage all aspects of their account in one place. The automated system features an animated Hurst van on screen which can be tracked in real time enabling customers to see their delivery.

Mark added: “Having our own dedicated transport fleet helps us ensure that our products always get to our customers on time, in full and, most importantly, in satisfactory condition. When it comes to distribution, we strive to deliver a first-class service.”

For more information on Hurst, call 01482 790790 or visit www.hurstdoors.co.uk.

Edgetech may be best known for its internationally recognised warm-edge spacer technology, but the Quanex company is experiencing rapidly rising demand for another cutting-edge product it offers.

TruFit is a state-of-theart window installation tape. Made of open-cell polyurethane foam and filled with a flame-retardant synthetic resin, it provides a much quicker, cleaner and more thermally efficient alternative to traditional silicone.

Once the tape’s backing paper is removed, it gradually expands to seal

the window fully, ensuring it offers exceptional all-round performance – protecting against mould, and providing first-class thermal and acoustic insulation.

In addition to this, it’s much easier to apply than silicone and can be used in all weathers.

Edgetech Head of Marketing

Charlotte Hawkes suggests these reasons are behind the growth of interest in TruFit:

“The biggest factor driving the surge of interest in TruFit is clearly energy efficiency.

“Installers have always been very impressed with TruFit when they’ve seen it but, in the past, they have often chosen to stick with what they know.

“For many of those installers, the last year has been a tipping point. The huge rises in household energy prices, combined with continuing pressure to help the country reach net zero, has led to a surge in

the numbers of customers enquiring about TruFit.

“It’s an incredibly effective tool for helping installers fit windows and offers outstanding thermal performance – in addition to being quicker, cleaner and easier to use than silicone.